Operation – York SUNLINE 2000 D1EE 048 User Manual

Page 12

The heaters are wired for a single point power supply. Power

supply need only be brought into the single point terminal block

and thermostat wiring to the low voltage terminal strip located

in the upper portion of the unit control box.

Fuses are supplied, where required, by the factory. Some KW

sizes require fuses and others do not. Refer to the accessory

instruction for electrical data.

COOLING SYSTEM

The cooling section is a complete factory package utilizing an

air-cooled condenser. The system is factory-charged with

Refrigerant-22. The compressor is hermetically sealed and

internally sprung.

The compressors have inherent (internal) protection. If there is

an abnormal temperature rise in the compressor, the protector

will open to shut down the compressor.

PRELIMINARY OPERATION COOLING

After the installation has been completed, the crankcase

heater of the compressor must be energized for at least 4 hours

before starting the unit. After this initial warm-up, the

compressor should be given three false starts (energized just

long enough to make a few revolutions) with a 5 minute delay

between each start before being put into full time service.

NOTE: Prior to each cooling season, the crankcase heater

must be energized at least 10 hours before the system

is put into operation.

COOLING SEQUENCE OF OPERATION

Single-Stage Cooling:

When the thermostat calls for “cooling”, “R” is closed to “G” and

“Y1" (wiring schematic) which completes the low voltage

control circuit, immediately energizing the compressors,

condenser fan motor and blower motor simultaneously.

Two-Stage Cooling:

A two-stage cooling thermostat may be used if the unit has an

economizer. First-stage cooling is provided by the economizer

if the outdoor air enthalpy is acceptable, and second-stage

cooling is provided by the compressor. Jumper wire J1 must be

removed. Refer to unit wiring diagram.

After the thermostat is satisfied and opens, the blower will

continue to run for a short time. All other components will stop.

SAFETY CONTROLS

The refrigerant system is equipped with the following safety

controls:

1. A Suction Line Freezestat to protect against low evaporator

temperatures due to a low air flow or a low return air tem-

perature.

2. AHigh Pressure Cutout Switch to protect against excessive

discharge pressures due to a blocked condenser coil or a

condenser motor failure.

3. A Low Pressure/Loss of Charge

Switch to protect against loss of refrigerant charge.

If either of the above safety controls opens, the refrigerant

system will be locked out. The lock out of the system can be

reset by opening the 24V circuit either at the room thermostat

or at the unit disconnect.

HEATING SEQUENCE OF OPERATION

The following sequence of operation is based on using a

standard single-stage or two-stage heating thermostat.

WITH POWER TO UNIT AND THERMOSTAT IN THE

HEATING MODE

Single-Stage Heating:

a. If the fan switch is in the “ON” position, the evaporator

blower motor relay (BR) will be energized through terminal

G to provide continuous blower operation. If the fan switch

is in the “AUTO” position, the blower will operate only when

there is a call for heating by the thermostat.

b. Upon a call for heat by the thermostat, the first stage of heat

will be energized. Sequencer 1S (or contactor 2M) is al-

ways the first and last to complete its timing cycle and con-

trols power to the evaporator blower motor.

c. The thermostat will cycle the electric heat to satisfy the

heating requirements of the conditioned space.

Two-Stage Heating:

a. If the fan switch is in the “ON” position, the evaporator

blower motor relay (BR) will be energized through terminal

G to provide continuous blower operation. If the fan switch

is in the “AUTO” position, the blower will operate only when

there is a call for heating by the thermostat.

b. Upon a call for first-stage heat by the thermostat, the first

stage of heat will be energized.

If the thermostat calls for the second stage of heat, the

second stage of heat will be energized.

As before, sequencer 1S (or contactor 2M) maintains

control of the evaporator blower.

c. The thermostat will cycle the electric heat to satisfy the

heating requirements of the conditioned space.

CONTINUOUS BLOWER - Continuous blower operation is

possible by closing the R to G circuit on the thermostat.

035-12046-003-A-0204

12

Unitary Products Group

OPERATION

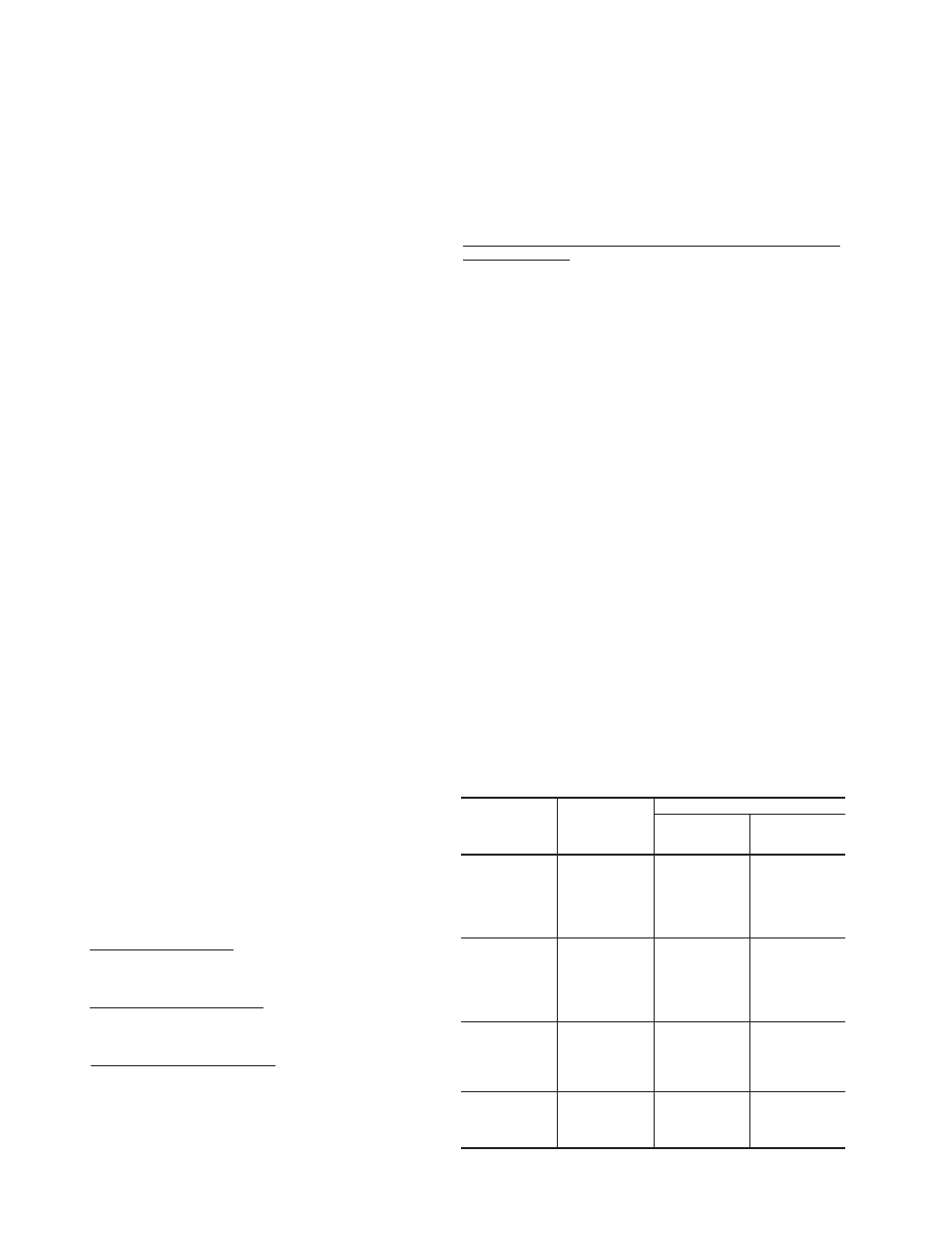

NOMINAL

HEATER

SIZE

KW

VOLTAGE

SETTING, AMPS

TH1

TH2

5

7

10

15

20

30

240-1-60

0.16

0.35

0.35

0.35

0.35

0.35

-

-

-

0.19

0.38

0.38

5

7

10

15

20

30

240-3-60

0.35

0.35

0.35

0.35

0.35

0.35

-

-

-

0.19

0.38

0.38

7

10

15

20

30

480-3-60

0.35

0.35

0.35

0.37

0.37

-

-

-

0.29

0.29

10

15

20

30

600-3-60

0.35

0.35

0.37

0.37

-

-

0.29

0.29

TABLE 10 - HEAT ANTICIPATOR SETTING