Warning, Fig q spring turn chart, Winding springs – Wayne-Dalton 451 User Manual

Page 12

12

DOOR HEIGHT

400-8

400-12

5250-18

800-32

6’6”

7.5

7.5

7’0”

7.875

7.875

7’6”

8.5

8.5

8’0”

8.875

8.875

6.75

8’6”

9.25

7.125

9’0”

9.5

7.375

9’6”

10.125

7.75

10’0”

10.5

8.125

5.375

10’6”

11

8.375

5.625

11’0”

11.5

8.875

5.875

11’6”

12

9.125

6

12’0”

12.5

9.5

6.25

12’6”

9.875

6.5

13’0”

10.25

6.75

13’6”

10.5

7

14’0”

10.875

7.375

14’6”

11.25

7.5

15’0”

11.5

7.625

15’6”

11.875

8

16’0”

12.25

8.125

16’6”

12.5

8.25

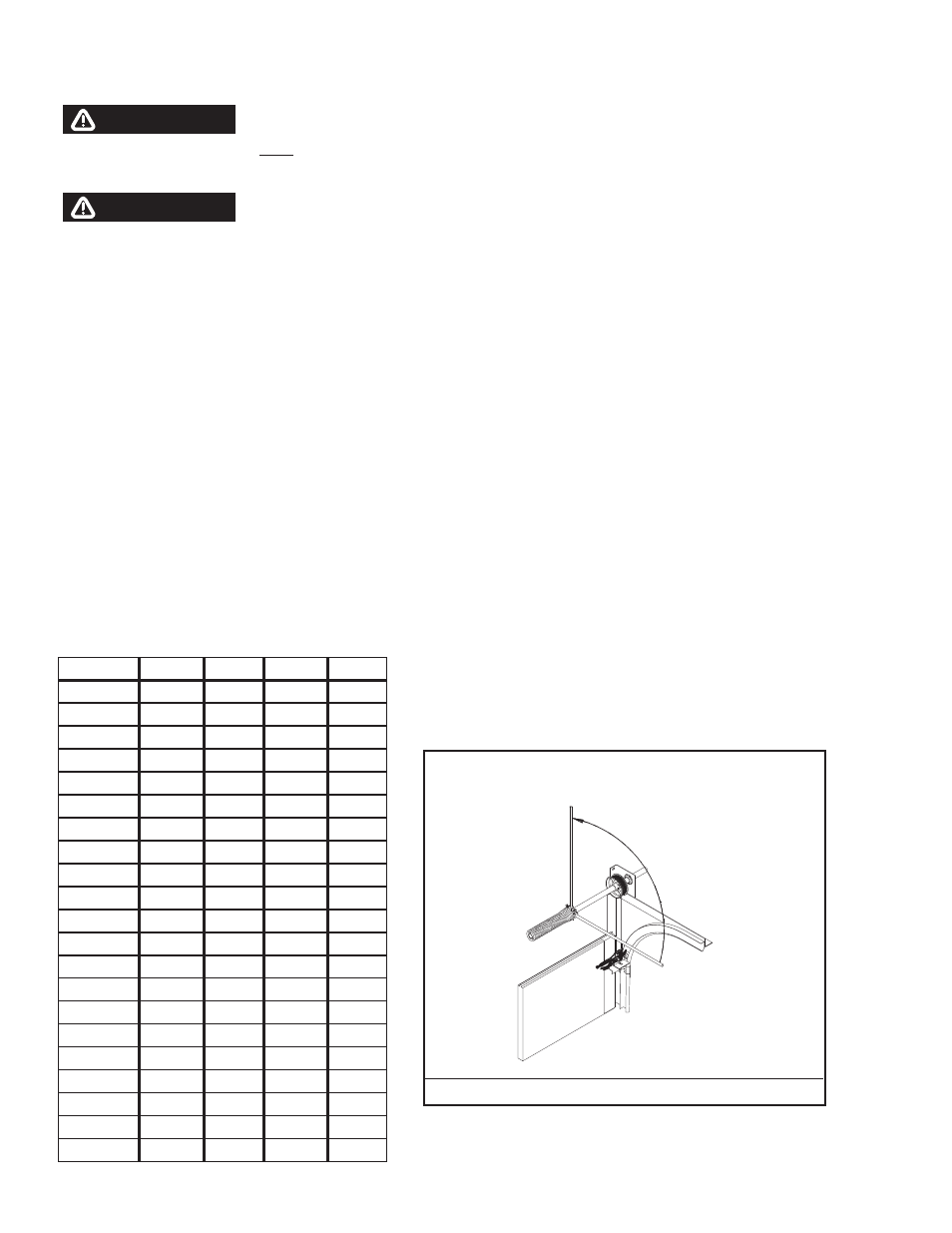

FIG Q

SPRING TURN CHART

WIND SPRINGS

TOWARD CEILING.

(STANDARD LIFT

APPLICATIONS)

WARNING

WARNING

WINDING SPRINGS

APPLY LOCKING PLIERS TO THE TRACKS ABOVE THE THIRD ROLLER, OR LOCK DOOR IF APPLICABLE, BEFORE WINDING THE SPRING(S) TO PREVENT DOOR FROM

RISING UNEXPECTEDLY, POSSIBLY RESULTING IN SEVERE OR FATAL INJU RY.

WINDING BARS MUST FIT SNUGGLY INTO HOLES IN SPRING WINDING CONES. ATTEMPTING TO WIND SPRINGS WITH LOOSELY FITTING RODS, SCREWDRIVERS OR

OTHER IMPROPER TOOLS CAN RESULT IN SEVERE OR FATAL INJURY.

Feed the cable attached to the left hand bottom bracket up the vertical track, behind the rollers and secure to the left hand drum. Push the drum up against the end

bearing bracket and secure to the shaft by tightening the set screws (solid shafts use 1/4” key(s) and set screws to secure drums).

Rotate drum and shaft until cable is taut, then apply locking pliers to torsion shaft with end resting against header. This will hold cable taut and on drum. There must be

at least 1/2 wrap of cable on the drum. If not, contact Wayne-Dalton for proper length cables. Attach other cable to right hand drum. Push drum against end bearing

bracket and rotate drum until cable is taut. Secure drum to shaft by tightening the set screws. Cable tension must be equal on both drums on single shaft applications.

On split shaft applications, apply locking pliers to both torsion shafts, and secure bolts in coupling after springs are fully wound.

Carefully, following spring winding instructions detailed in FIG Q, wind spring(s), using the appropriate 1/2”, 5/8” or 3/4” diameter winding rods of suffi cient length; wind

spring 1/4 turn at a time to the number of complete revolutions recommended on the spring turn chart. When the proper number of turns is reached, tighten the set

screws on the winding cone. Release the locking pliers from the spring shaft(s). Adjust the coupler on split solid shafts until drums are in line (check door level) and

tighten coupler.

NOTE: Coupling used on solid shaft only. Tighten connecting bolts after winding springs.