How to deal with error codes, Error code display examples, Menus – Watlow Electric Micro-Based Autotuning Control SERIES 980/985 User Manual

Page 32

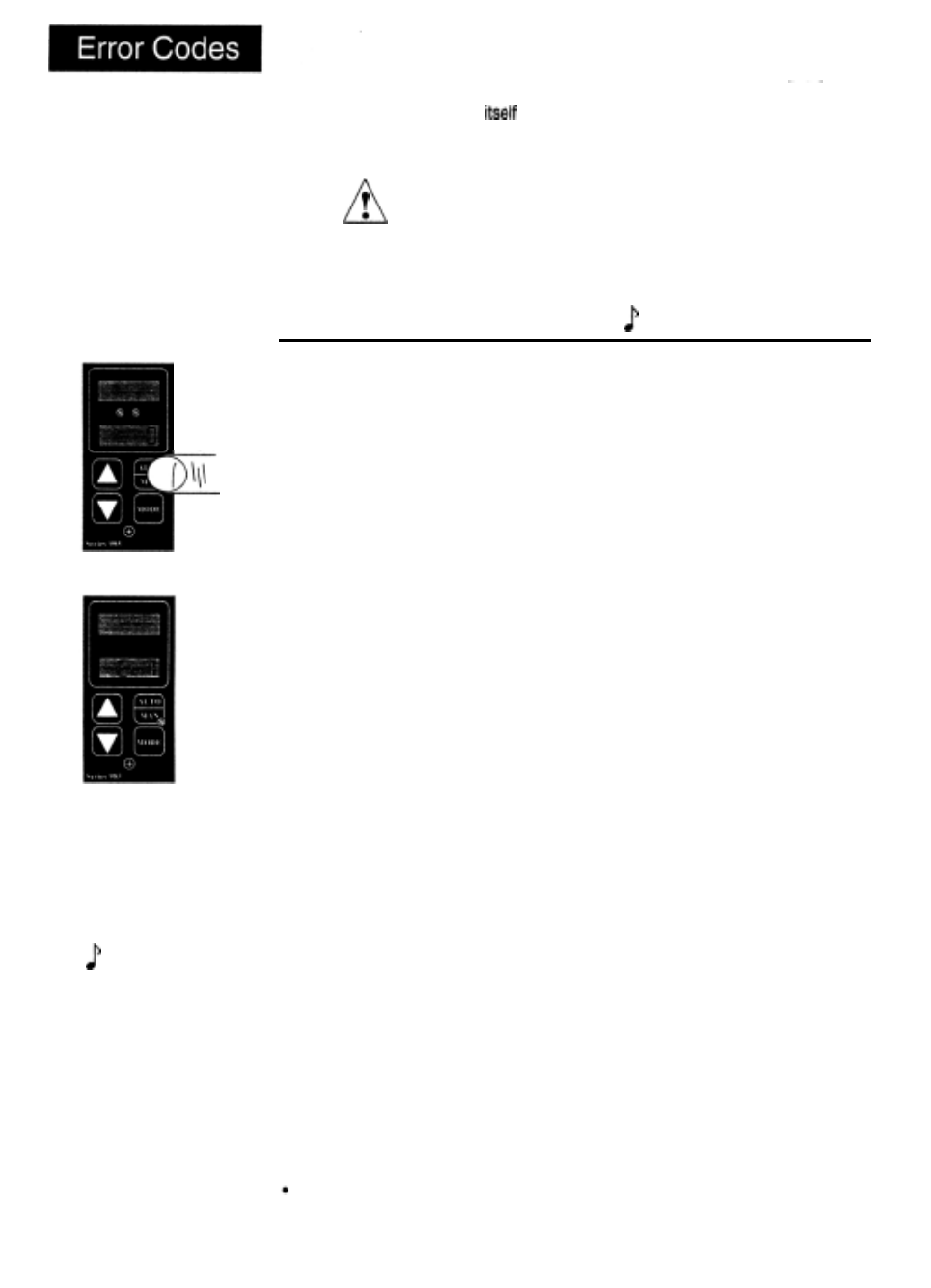

Press

~ twice-

Read

error

Figure 32 -

Error Code Display

Examples

NOTE:

Electrical noise or a

noise event, vibra-

tion or excess

environmental

moisture or tem-

perature may cause

Series 985 errors to

occur.

If the cause

of an error is not

otherwise apparent,

check for these.

•If the alarm is non-latching...

The alarm will clear

automatically as soon as the process

temperature is inside the alarm limit by 3°F/l.7°C for 1° RTD units, or

0.3°F/0.

17°C for 0.1° RTD units.

l

CAUTION:

An alarm display will be masked by an error condition or when the

control is in the Calibration or Set Up

Menus.

How To Deal With Error Codes

Three dashes, “- - -", in the upper display indicate a Series 985 error.

l

If operator access is LOC 0 or

1 . . .

l

Press the AUTO/MAN key twice to see the error code for one

second.

•

If operator access is LOC 2 or 3...

l

The error code is already in the lower display.

•

Error code definitions and actions...

Er 1 -

Sensor overrange error

The sensor input is generating a value that is higher than that allowed for

the range of this sensor, or the A/D circuitry is not functioning properly.

Enter a valid input.

Er 2 -

Sensor underrange error

The sensor input is generating a value that is lower than that allowed for

the range of this sensor, or the A/D circuitry is not functioning properly.

Enter a valid input.

Er 3 -

Ambient error

Check the specification for the ambient temperature range.

Er 4 -

Configuration error

The unit’s microprocessor is faulty; call the factory.

Er 5

-

Non volatile checksum error

The nonvolatile memory checksum has discovered a checksum error.

Unless a momentary power interruption occurred while the unit was

storing data, the nonvolatile memory is bad. Call the factory.

Er 7 -

A/D overflow error

The A/D circuit is over- or under-range. An open or reversed polarity

sensor is the most likely cause. Check the sensor; if it is connected and

functioning properly, then call the factory.

To clear a corrected error...

l

Cycle power to the control.

32

WATLOW Series 980/985 User’s Manual

Tuning and Operating, Chapter 5