Installation – Trane WPVJ User Manual

Page 15

WSHP-SVX04A-EN

15

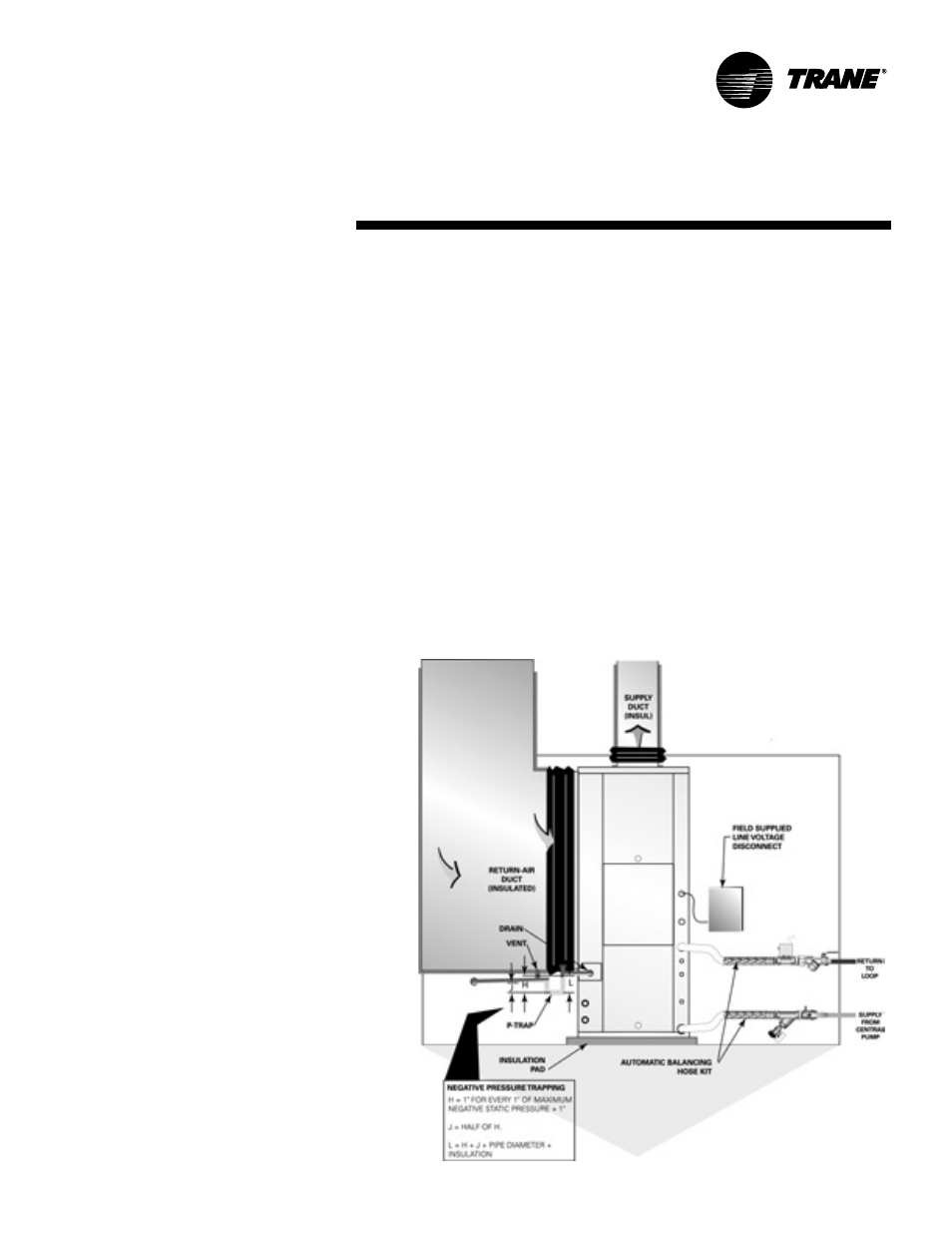

Unit Installation; WPVJ

Duct collars are provided for the WPVJ

equipment. The duct system and dif-

fusers should be sized inaccordance

with ASHRAE or ACCA Manual D.

1 Install a flexible connector (field

provided) for supply/return air duct

connections on all metal duct sys-

tems.

Note: If the unit is connected to ex-

isting ductwork, an initial check of

the mechanical system should be

made to insure the duct has the ca-

pacity to handle the air required for

the unit application. If ducting is too

small, as in the replacement of heat-

ing only systems, larger ductwork

should be installed. All existing

ductwork should be checked for

leaks, and repairs should be made.

2 Insulate the field ductwork with a

minimum of 1" duct insulation.

Note: Installing the unit to an unin-

sulated ductwork in an uncondi-

tioned space may adversely affect

the unit’s performance, as well as in-

crease noise emissions into the

space.

3 Install proper condensate trapping

to the equipment. The unit drain

connection is 3/4" (19mm). When de-

signing the condensate trap, it is im-

portant to consider the unit’s draw-

thru design requiring negative pres-

sure trapping.

In a properly trapping system, when

condensate forms during normal

operation, the water level in the trap

rises until there is a constant flow

(Figure 3). It is imperative to main-

tain water in the trap and not allow

the trap to dry out during heating

season. Keeping the trap primed at

all times will enable the water to

flow properly.

Condensate piping must be installed

to allow the cleanable condensate

pan to be removed for cleaning.

Minimum clearances for drain pan

removal are 22" (sizes 018 and 024),

25" (sizes 030 and 042), and 27" (siz-

es 048 through 072).

4 Flush System. See page 17 for sys-

tem flushing.

Water Connection

For vibration isolation, it is recom-

mended that flexible steel braided

hoses be installed instead of hard pip-

ing between the supply/return risers

and the equipment.

Trane offers 4-types of hose kit varia-

tions:

• Stainless steel braided flexible

hose with manual shut-off (ball)

valves

• Stainless steel braided flexible

hose with manual deluxe shut-off

(ball) valves

• Stainless steel braided flexible

hose with manual circuit-setter

valve

• Stainless steel braided flexible

hose with automatic balancing

valve

Additional accessories, such as a

strainer are recommended for use to

eliminate contaminants from entering

the co-axial water-to-refrigerant heat

exchangers.

Installation

Figure 3: Negative pressure trap