Data sheet: maxeta, Ifa series, Input/output ripple and noise measurements – TDK Maxeta iFA Series User Manual

Page 18: Safety considerations

Data Sheet: Maxeta

TM

iFA Series

©2002-2006 TDK Innoveta Inc.

iFA 28V 600W Advance Datasheet 8/3/2006

℡

(877) 498-0099

18/19

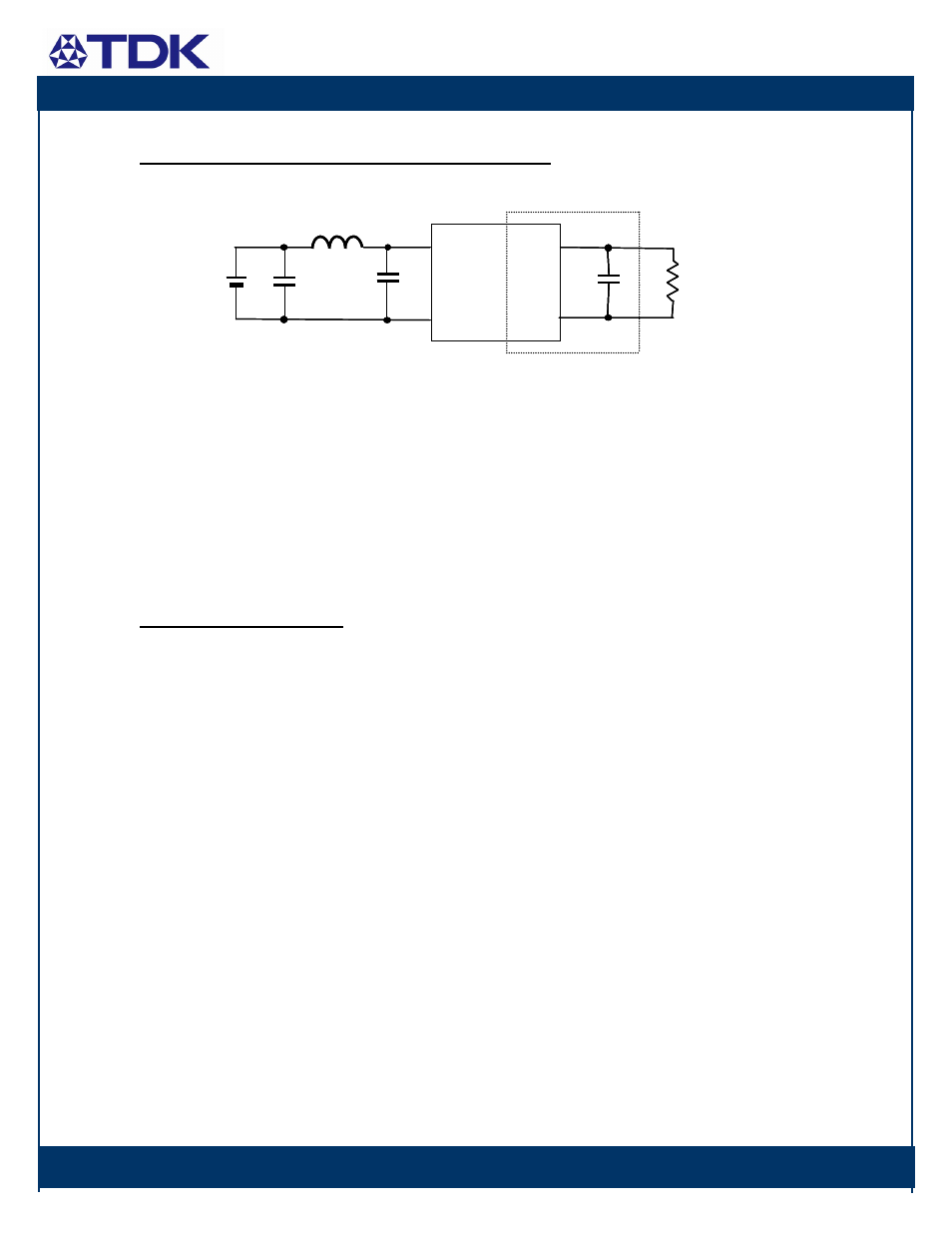

Input/Output Ripple and Noise Measurements:

The input reflected ripple is measured with a current probe and oscilloscope. The ripple current is the current through the

15uH inductor, Lin, with esr

≤ 10 mΩ, feeding a capacitor, C1, esr ≤ 700 mΩ @ 100kHz, across the module input voltage

pins. The capacitor C1 across the input shall be at least 100

µF/100V. A 470µF/100V or two 220µF/100V capacitors in

parallel is recommended. A 220

µF/100V capacitor for C0 is also recommended.

The output voltage ripple measurement is made approximately 5 cm (2 in.) from the power module using an oscilloscope

and BNC socket. The capacitor Cext consisting of a 0.1

µ

F and a 10

µF ceramic capacitors and at least a 470µF or larger

aluminum electrolytic or tantalum capacitor (esr

≤ 300 mΩ) located about 5 cm (2 in.) from the power module. At Io <

Io,min, the module output is not required to be within the output voltage ripple and noise specification.

Safety Considerations:

All TDK Innoveta products are certified to

regulatory standards by an independent,

Certified Administrative Agency laboratory.

UL 1950, 3

rd

edition (US & Canada), and

other global certifications are typically

obtained for each product platform.

The iFA products have the following

certifications:

UL 60950 (US & Canada)

VDE 0805

CB Scheme (IEC 950)

CE Mark (EN60950)

For safety agency approval of the system in

which the DC-DC power module is installed,

the power module must be installed in

compliance with the creepage and clearance

requirements of the safety agency. The

isolation is basic insulation. For applications

requiring basic insulation, care must be

taken to maintain minimum creepage and

clearance distances when routing traces

near the power module.

As part of the production process, the power

modules are hi-pot tested from primary and

secondary at a test voltage of 1500Vdc.

When the supply to the DC-DC converter is

less than 60Vdc, the power module meets

all of the requirements for SELV. If the

input voltage is a hazardous voltage that

exceeds 60Vdc, the output can be

considered SELV only if the following

conditions are met:

1) The input source is isolated from the ac

mains by reinforced insulation.

2) The input terminal pins are not

accessible.

3) One pole of the input and one pole of

the output are grounded or both are kept

floating.

4) Single fault testing is performed on the

end system to ensure that under a

single fault, hazardous voltages do not

appear at the module output.

+

C0

C1

Vout

+

-

-

Lin

Vs

Vin

Cext

R

Load

Ground Plane

+

C0

C1

Vout

+

-

-

Lin

Vs

Vs

Vin

Cext

R

Load

R

Load

Ground Plane