System start up, Pilot valve operation, Troubleshooting – Toro 850S User Manual

Page 4: Pilot valve

System Start Up

_________________________________________________________

The following is a recommended procedure that will protect system components during system start-up. The procedure is based on a

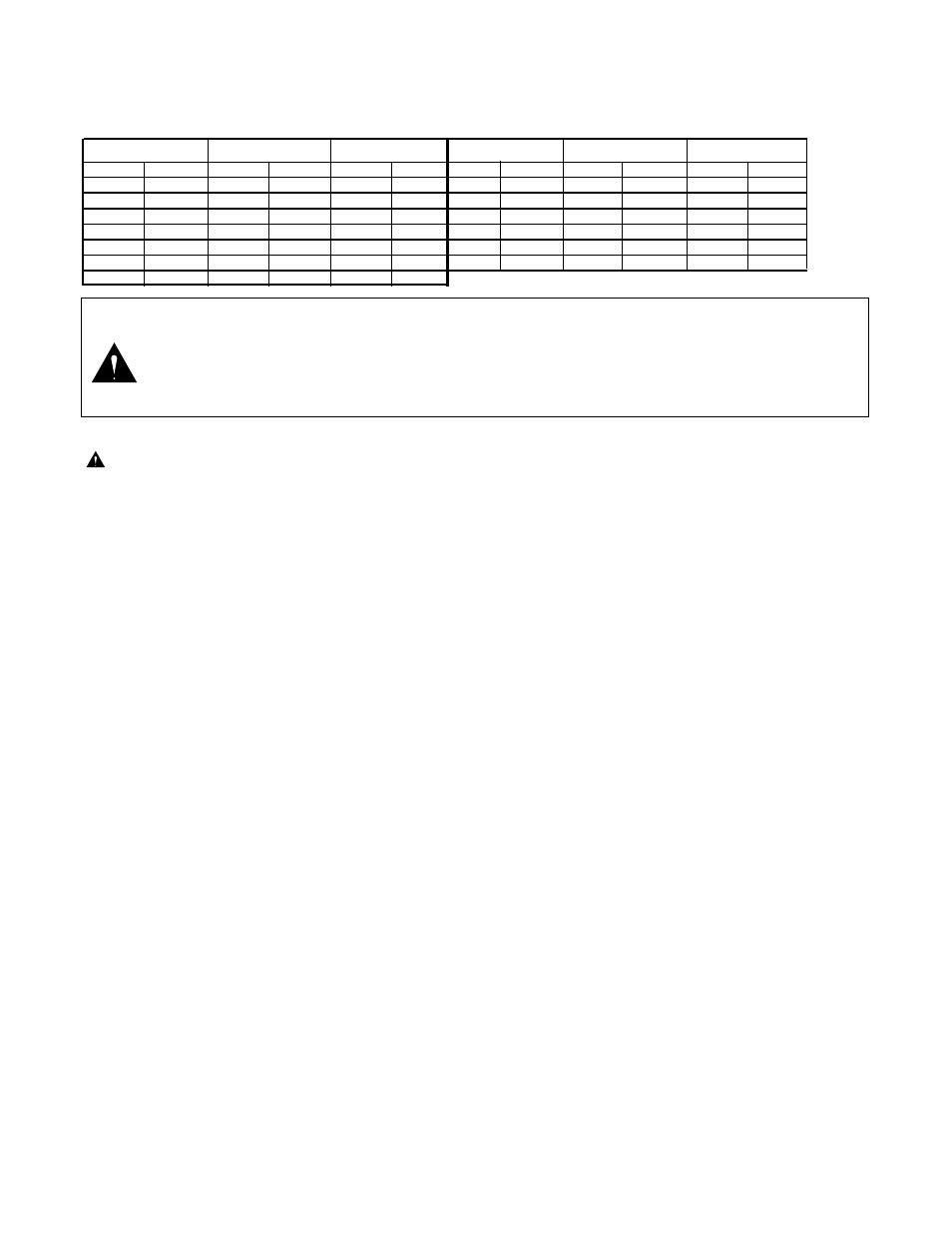

velocity fill rate of less than 2' (.61 m) per second. See Table 3 below.

Table 3: Recommended System Fill Rate

1. Use a jockey pump only to fill the system at a velocity fill rate of less than 2' (0.61 m) per second.

CAUTION: Failure to comply with recommended fill rate will increase line pressure resulting in a water hammer

effect that could damage sprinklers and piping components. See Warning above.

2. At all tees and greens use quick coupler keys with quick coupler valves to bleed air from the system lines during the filling

process. For best results, do not compress air and then relieve it – bleed the air constantly while filling the system.

3. After water has filled all lines and all air is removed, remove the quick coupler keys.

Pilot Valve Operation

(Electric Models Only)

________________________________________

The pilot valve controls the operation of the main valve located in the base of the sprinkler body. The main valve is operated by the release

of water metered through the pilot valve when it is activated either manually at the sprinkler or by the irrigation system controller.

The pilot valve regulates the water pressure to the sprinkler nozzle. Pressure regulation compensates for large variations within the

system and maintains a constant pressure for optimum sprinkler operation. The pilot valve is factory set to regulate one of four

pressure levels: 50 psi (3.4 bar), 65 psi (4.5 bar), 80 psi (5.5 bar) or 100 PSI (6.9 bar).

The sprinkler operation mode is set using a Toro Selector Tool (P/N 995-15) inserted through the body flange onto the pilot valve D-

shaped selector cam. The "AUTO" mode permits automatic operation from the system controller. The "ON" mode opens the main

valve for manual operation and "OFF" mode prevents the main valve from opening.

Troubleshooting

_________________________________________________________

■

Pilot Valve

Possible equipment failures with causes and corrective action are listed below.

PROBLEM

POSSIBLE CAUSE – CORRECTIVE ACTION

SPRINKLER WILL

(a) No 24 VAC to coil assembly. (Electric Models)

NOT TURN ON

– Measure voltage with a Digital Volt Meter (DVM). Check wiring and controller program.

– Refer to Controller Operating Instructions.

(b) Selector cam in "OFF" position.

– Set to "AUTO" position.

(c) Debris in pilot valve assembly.

– Disassemble and remove all debris. (See Servicing Pilot Valve page 11.)

(d) Insufficient pressure in controller supply line and/or sprinkler control tube. (N.C. Models)

– Check pressure.

SPRINKLER WILL

(a) Constant 24 VAC from controller. (Electric Models)

NOT SHUT OFF

– Check for voltage using a DVM. If voltage is present, disconnect wire.

If sprinkler closes, service controller. Refer to Controller Service Manual.

(b) Selector cam in manual "ON" position.

– Set to "AUTO" or "OFF" position.

(c) Debris in pilot valve assembly.

– Disassemble and remove all debris. (See Servicing Pilot Valve page 11.)

(d) Constant pressure from controller. (N.C. Models)

– Check pilot valve at controller for constant flow.

– Check elevation differential. Valve elevation should not exceed 0' above

controller elevation or 70' (21.3 m) below controller elevation.

4

WARNING

NEVER STAND OR LEAN OVER THE SPRINKLER WHILE THE IRRIGATION SYSTEM IS BEING FILLED,

DURING MANUAL OR AUTOMATIC OPERATION OR WHEN PERFORMING SPRINKLER SERVICE

PROCEDURES. DIRECT CONTACT WITH IRRIGATION SPRAY, A FAILED OR IMPROPERLY INSTALLED

SPRINKLER CONNECTION OR SPRINKLER COMPONENTS FORCIBLY EJECTED UPWARD UNDER

PRESSURE CAN CAUSE SERIOUS INJURY.

Pipe Size

Flow

Velocity

Pipe Size

Flow

Velocity

in.

cm

GPM

LPM

ft/sec

m/sec

in.

cm

GPM

LPM

ft/sec

m/sec

1/2

1.3

2

7.6

1.60

0.49

3

7.6

45

170.3

1.86

0.57

3/4

1.9

3

11.4

1.92

0.59

4

10.1

75

283.9

1.87

0.57

1

2.5

5

18.9

1.50

0.46

6

15.2

150

567.8

1.73

0.53

1-1/4

3.1

10

37.9

1.86

0.57

8

20.2

250

946.3

1.70

0.52

1-1/2

3.8

10

37.9

1.41

0.43

10

25.4

450

1703.0

1.97

0.60

2

5.0

20

75.7

1.80

0.55

12

30.5

500

1893.0

1.55

0.47

2-1/2

6.4

30

113.6

1.84

0.56