Important le canada seulement – TOA Electronics SSDV-3328 User Manual

Page 35

35

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Note - use extra care not to engage the

orifice strip with the 7/16" open end wrench

(contacting the orifice strip could cause strip

distortion rendering the pilot inoperative).

Also avoid wrench contact to any of the

other pilot parts.

Use a 7/16" open end wrench and turn the

pilot hex fitting counter-clockwise 1/4 turn.

(See Figure 62 ).

Note - The orifice strip tab may be randomly

located on any side of the hex fitting.

d. Push the orifice strip tab all the way

against the hex fitting to align the appropri-

ate gas type orifice (see Figures 61 & 62 ).

The type of gas for which the pilot is set,

is, the gas type shown on the tab.

e. Retighten, clockwise, the pilot hex

fitting until the pilot hood aligns with the

thermocouple and thermopile as indicated

by the arrows shown in Figure 62.

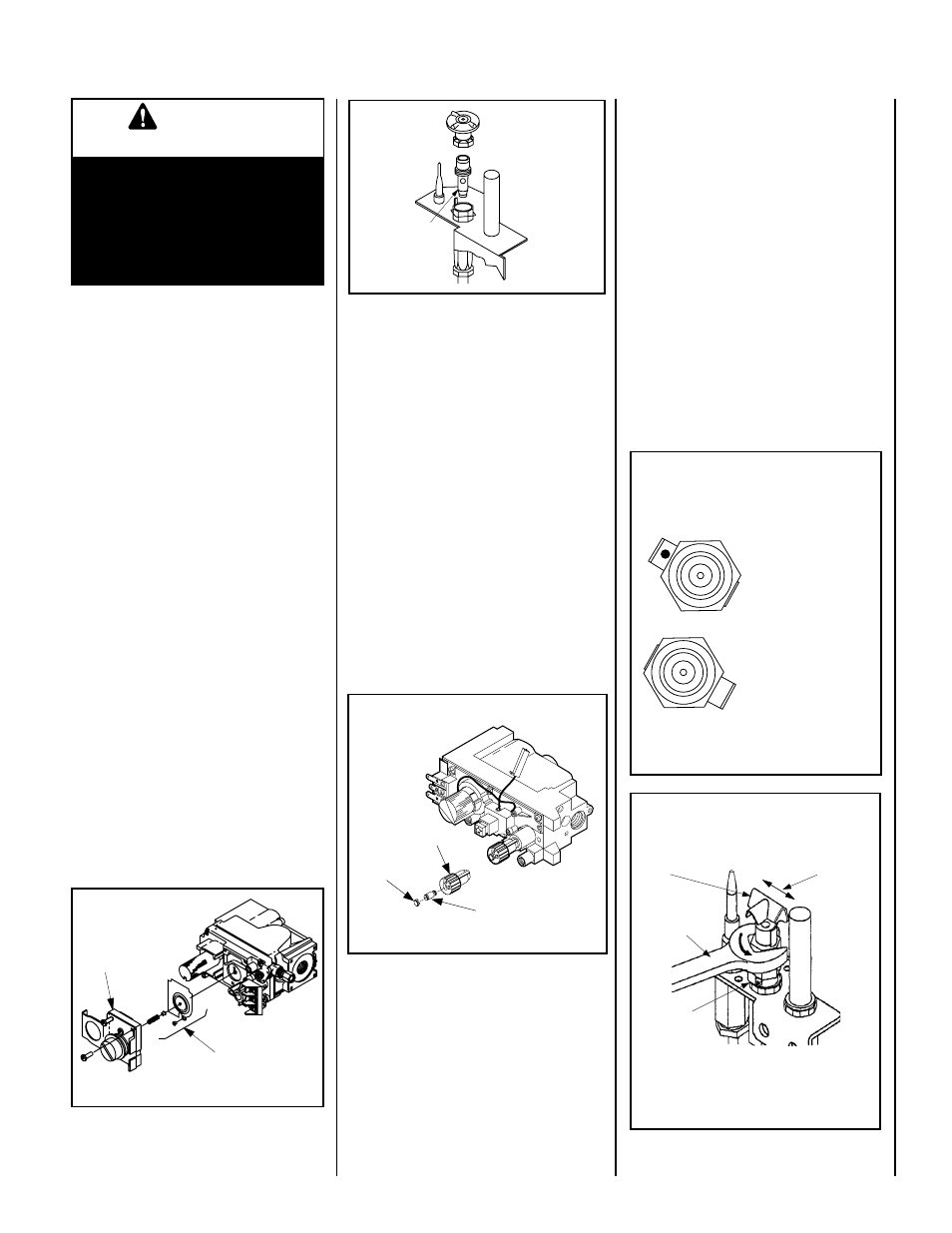

Adjusting Knob

Conversion screw

(blue natural gas;

red LP/propane gas)

Regulator Cap

Honeywell Millivolt Gas Valve

Figure 60

Pilot for Honeywell Millivolt Gas Valve

Figure 61

b. Attach manometer to the manifold side

pressure test fitting and verify manifold

pressure reads 3.5 inches water column

(0.87 kPa) for natural gas, and 10.0

inches water column (2.49 kPa) for pro-

pane gas.

c. Convert the pilot orifice as follows (see

Figures 61 & 62):

b. Attach manometer to the manifold side

pressure test fitting and verify manifold

pressure reads 3.5 inches water column (0.87

kPa) for natural gas, and 10.0 inches water

column (2.49 kPa) for propane gas.

c. Refer to Figure 59 and remove the pilot

hood assembly to access the hexed pilot orifice.

Remove and replace the orifice with the one

provided with the kit.

Step 5. Millivolt Appliances

Honeywell Systems -

a. Convert the gas valve as follows

(see Figure 60): Remove the plastic protecting

cap. Remove the gas type setting screw by

turning it counterclockwise. Obtain the replace-

ment gas type setting screw from the kit and

screw it into place (red for propane and blue

for natural gas). Tighten the gas type setting

screw by turning it clockwise. Replace the

plastic protecting cap.

Pilot for Honeywell Millivolt Gas Valve

(Loosening of Hex Fitting For

Orifice Strip Tab Positioning)

Figure 62

7/16 in. Open

End Wrench

Hood

Hood

Alignment

Orifice

Strip Tab

Take care not to contact the orifice strip tab

with the hex fitting wrench - distortion of the

tab may render the pilot inoperative.

LP (propane) Gas Posi-

tion - 1/16 inch hole,

LP and red color shown

on tab.

Natural Gas Position

- NAT shown on tab.

Top View of Hex Fiting and Orifice Strip Tab

Orifice Strip Tab Position Identification

For LP (propane gas) and Natural Gas

P

L

NA

T

SIT Millivolt Gas Valve

Pilot for SIT Millivolt

Gas Valve

Pressure

Regulator

Remove

These

Components

Figure 58

Pilot

Orifice

Gas conversion kits are available to adapt the

appliance from the use of one type of gas to

the use of another. These kits contain all the

necessary components needed to complete the

task including labeling that must be affixed to

ensure safe operation.

Kit part numbers are listed here and the following

steps detail the conversion procedure.

Step 1. Turn off the gas supply to the appliance.

Remove the front glass door/frame from the

appliance. Access the control compartment.

Step 2. Carefully remove the logs. Exercise care

so as not to break the logs.

Step 3. Locate the screws securing the burner

assembly to the appliance. Remove the burner

assembly and retain the securing screws.

Step 4. Millivolt Appliances - SIT Systems

a. See Figure 58 and the instructions

provided with the kit. Using a Torx T20,

tool or or standard flat screwdriver remove

and discard the three pressure regulator

mounting screws. Remove the pressure

regulator, spring, poppet, diaphragm and

bushing. Discard all removed components.

Ensure the rubber gasket installed on the

back of the replacement pressure regulator

is properly positioned and install the new

pressure regulator using the new screws

supplied with the kit. Tighten screws to 25

In. lb. torque.

IMPORTANT

LE CANADA SEULEMENT

La conversion devra être effectuée

conformément aux recommanda-

tions des autorités provinciales

ayant juridiction et conformément

aux exigences du code d'installation

CAN1-B149.1 ET.2.

Figure 59