Control of roller pressure – Royal Sovereign 1050 User Manual

Page 11

RSH-1050/1650

RSR-685/1050

1. Set up cold film below the upper bar of the machine

(Set the same as method of HOT film for protect paper of lower part)

2. Set the pressure Lever to the 15mm, open mode

3. Insert a piece of wide cardboard (guiding paper/carrier) between the rollers

4. Pull the film from the upper roller passing over the upper idle bar to the upper

roller and put it on the upper roller.

5. Put the paper back of the film to the bobbin at take-up bar to rewind

the paper back.

6. Allow some of the film with melted resin to stick to the Guiding Paper.

7. Place the film from lower shaft beneath the film from the upper roller which is

already melting and unwind films of both rollers 30~40Cm(1~1.3ft) for loosing

the tension.

8. Set the pressure Lever to the 1mm

9. Set speed at 1 and press Run button. The films will be fed into the machine and

will come out from the rear site of machine

10. Check the status of lamination and place the pressure lever at lamination mode

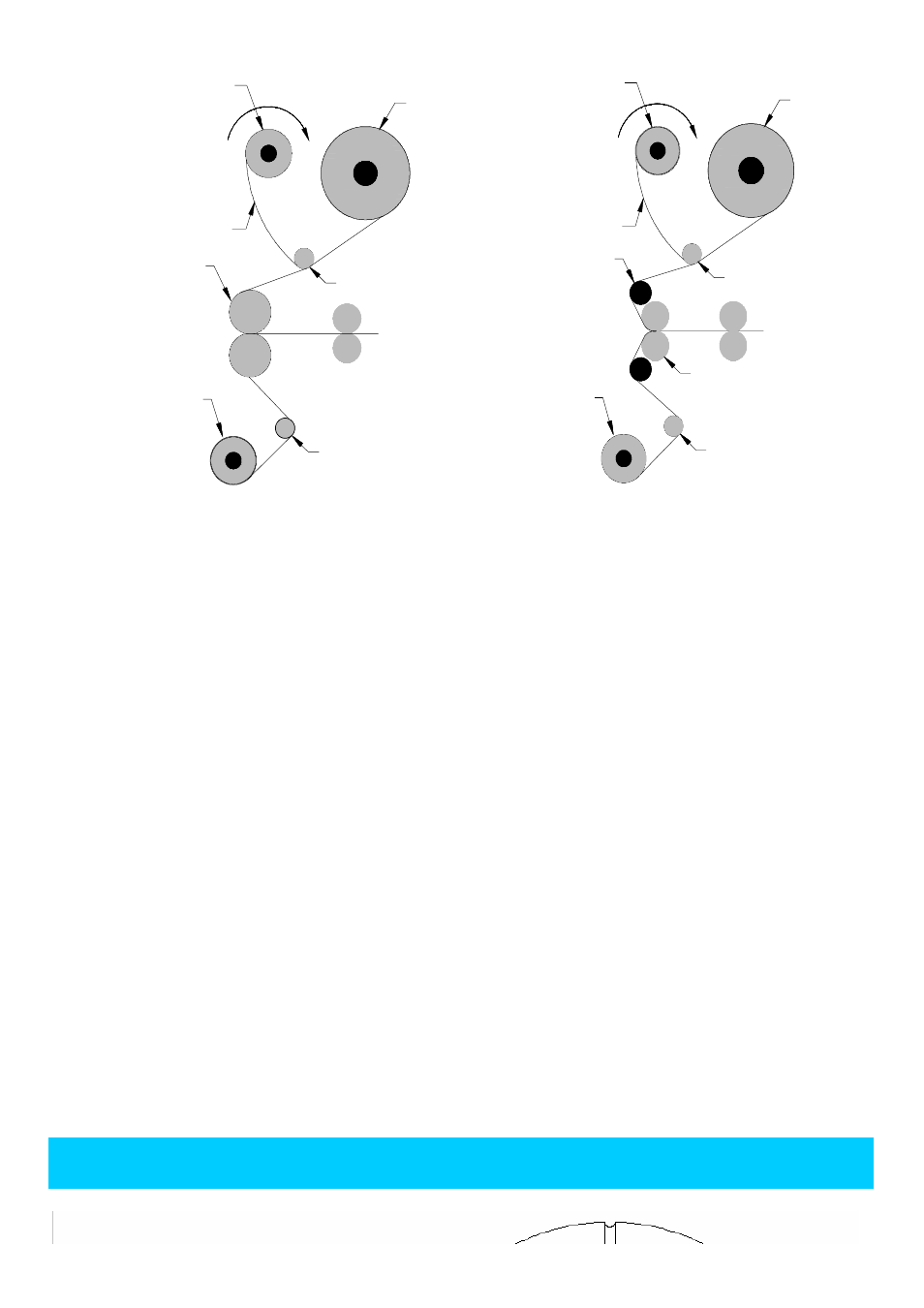

CONTROL OF ROLLER PRESSURE

TAKE UP DEVICE

PAPER BACK

COLD FILM

UPPER IDLE BAR

LOWER IDLE BAR

HOT ROLLER

PAPER BACK

UPPER IDLE BAR

PAPER BACK

LOWER IDLE BAR

HOT METAL ROLLER

TAKE UP DEVICE

COLD FILM

ROLLER

PAPER BACK

- 11 -