Raypak LONMARK Y-200 User Manual

Page 8

8

Notes:

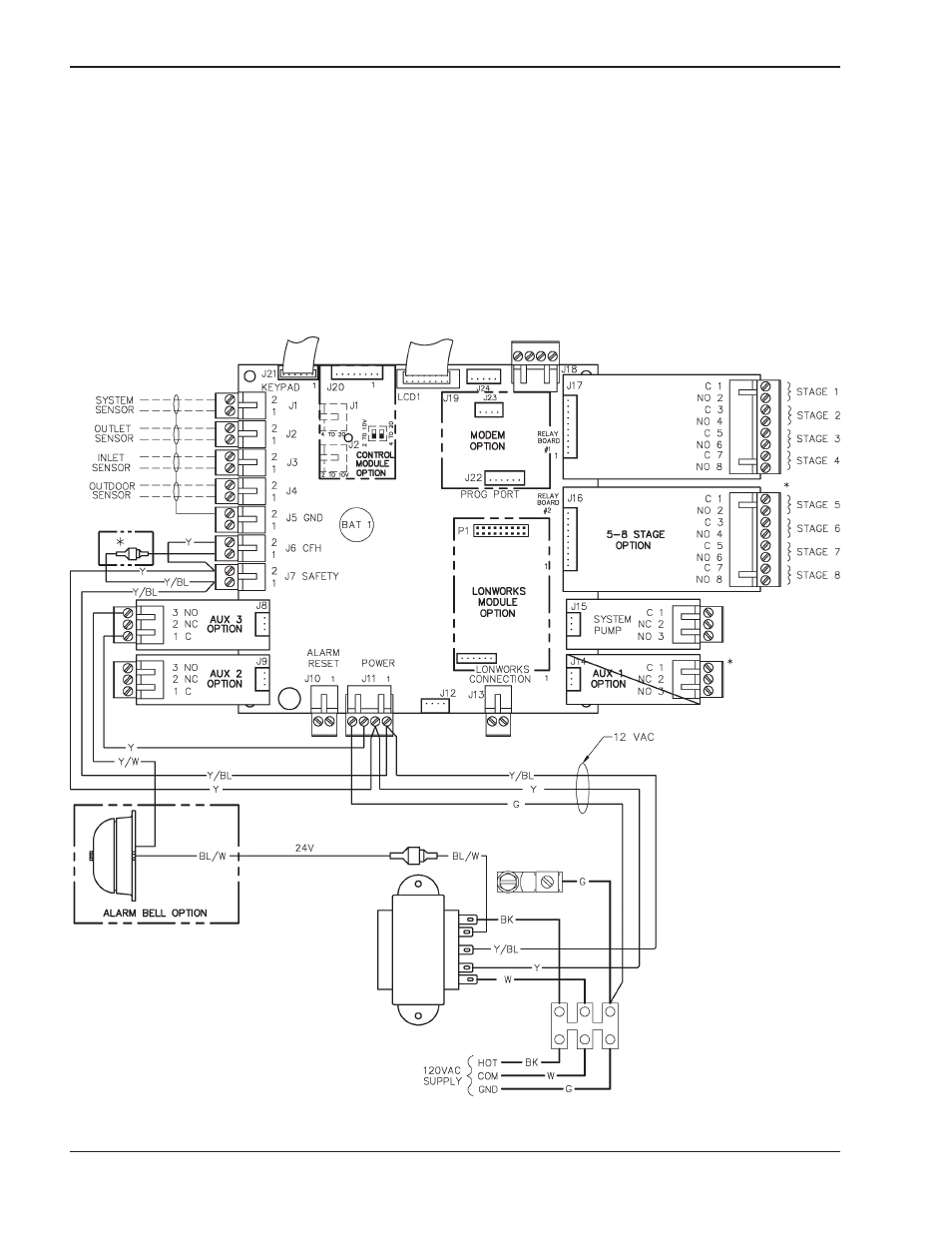

1. Tighten terminal strip clamping screws to 2.5 in-

lbs. Breakage from over-torquing is not covered

under warranty.

2. Use stranded copper conductors only. For supply

connections, use wires sized on the basis of 60°C

(140°F) ampacity and rated a minimum 90°C

(194°F).

3. Install disconnect for each control unit.

Fig. 3: Wiring Diagram

4. For external building control or thermostat control,

remove wiring to J6 (CHF) connector and activate

with 12 to 28 VAC.

See also other documents in the category Raypak Water boiler:

- 240692 (31 pages)

- HIDELTA 992B (68 pages)

- 1000 (74 pages)

- RAYTHERM 962-1826 (2 pages)

- 335 (1 page)

- 504-2004 (4 pages)

- 265 (14 pages)

- 751-1501 (2 pages)

- HI DELTA HD401 (48 pages)

- DEL TA LIMITED 899B (5 pages)

- 2100 - 4001 (2 pages)

- H-0042B (4 pages)

- 2005 (8 pages)

- HI DALTA HD401 (48 pages)

- XFYRE 400 (8 pages)

- 42 & 66 (2 pages)

- 992BE (5 pages)

- 500 (56 pages)

- 182-400 (2 pages)

- Gas Fired Boiler (8 pages)

- MVB 5042004 (56 pages)

- B0147 (43 pages)

- RAYTHERM 0042B (40 pages)

- WH 0090A (28 pages)

- H7 504-2004 (2 pages)

- 503-2003 (60 pages)

- XFYRE NINETY PLUS 850 (8 pages)

- XPAK 85 (68 pages)

- 0066B (38 pages)

- 195A (28 pages)

- Power Vent Raytherm 4001 (2 pages)

- FlexGas (1 page)

- XPAK 120 (12 pages)

- XTHERM 1505 (8 pages)

- RayTherm Commercial Boilers And Water Heater (4 pages)

- 0135B (6 pages)

- RayTemp Hot Water Energy Management Control (30 pages)

- 0090B (39 pages)

- B6000 (51 pages)

- B6000 (2 pages)

- 1001 (76 pages)

- RAYTHERM 133-4001 (44 pages)

- HI DELTA SS HD401 (4 pages)

- XFYRE 300-850 (2 pages)

- 30B (4 pages)