Rhinotek F-4243C User Manual

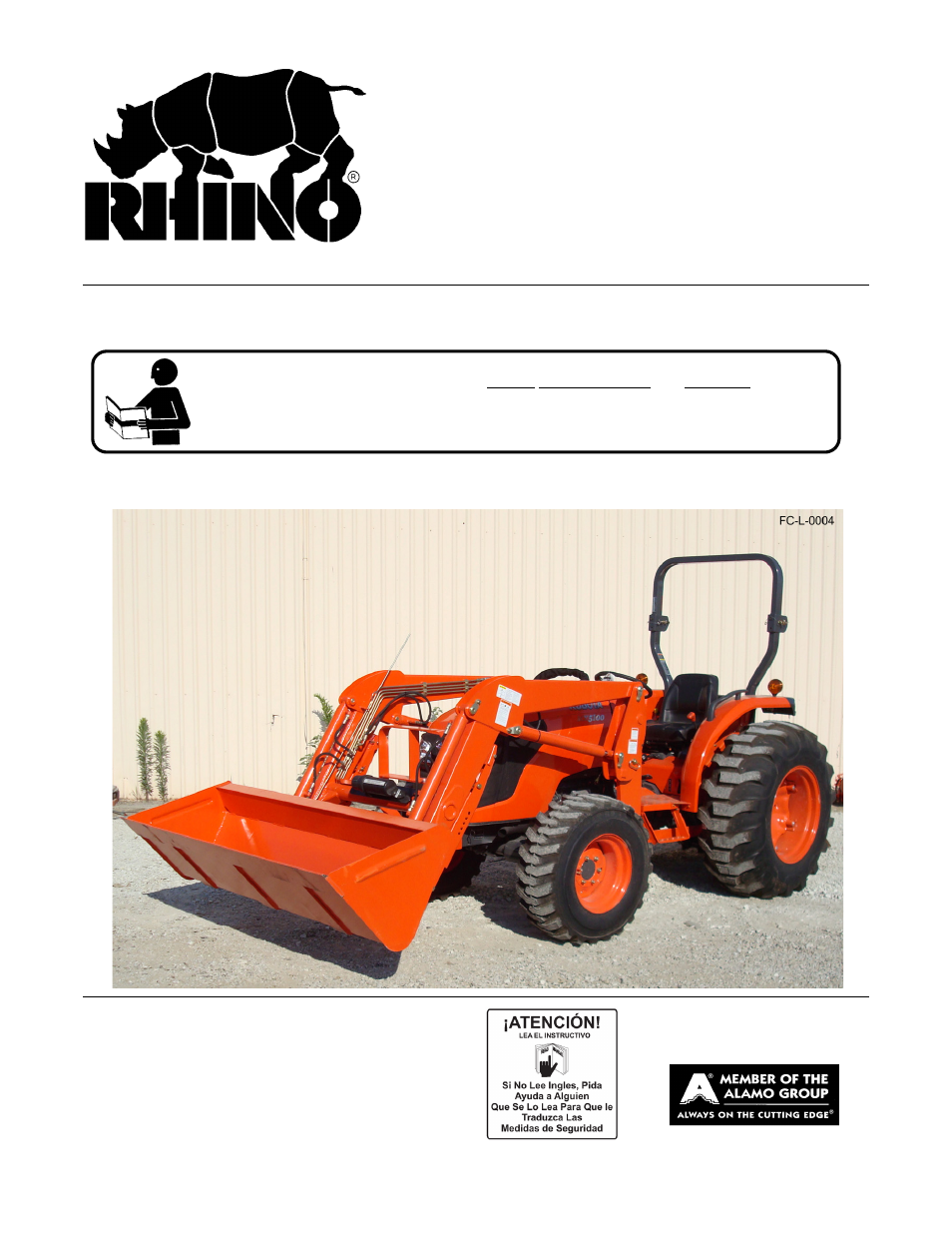

Operator’s manual, Loader

© 2011 Alamo Group Inc.

$0.00

1625

Published 01/11

Part No.

F-4243C

OPERATOR’S MANUAL

RHINO

®

1020 S. Sangamon Ave.

Gibson City, IL 60936

800-446-5158

Email: [email protected]

LOADER

This Operator's Manual is an integral part of the safe operation of this machine and must

be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety

and Operation Instructions contained in this manual before operating the equipment. C01-

Cover

Table of contents

Document Outline

- 1625

- OPERATOR’S MANUAL

- To the Owner/Operator/Dealer

- TABLE OF CONTENTS

- General Safety Instructions and Practices

- Connecting or Disconnecting Implement Safety Instructions and Practices

- Transporting Safety Instructions and Practices

- Maintenance and Service Safety Instructions and Practices

- Storage and Parking Safety Instructions and Practices

- Concluding Safety Instructions and Practices

- Decal Location

- 1. D469 1 WARNING Loader Safety

- 2. D468 2 DANGER Crushing, Electrocution, Falling Hazard

- 3. D471 1 WARNING Handling Bales

- 4. 52740 1 WARNING Oil Leaks

- 5. D470 1 DANGER Use ROPS, Seatbelt, Rear Ballast

- 6. 52203 1 WARNING Lock Valve in Transport

- 7. 55277 2 MODEL 1625

- 8. 49696 1 LOGO Rhino, Left

- 9. 51448 1 LOGO Rhino, Right

- 10. 03200347 * REFLCTR SMV Sign

- 11. 00776031 1 ________ Canister, Operator’s Manual

- 12. 55580 1 ________ Sheet, Decal; includes two D516 Decals (Note: For Optional Quick Attach Device Only)

- Decal Description

- Decal Location

- Federal Laws and Regulations

- SAFETY SECTION

- 1. Carefully read the Operator’s Manual, completely understand the Safety Messages and instructions, and know how to operate correctly both the tractor and implement.

- 2. Fill out the Warranty Card in full. Be sure to answer all questions, including the Serial Number of the implement. Mail within 30 days of delivery date of this implement.

- 3. Record the Loader Model and Serial Numbers on the Warranty page. Keep this as part of the permanent maintenance file for the implement

- Assembly Instructions

- Proper Ballasting and Wheel Spacing

- Tractor and Loader General Information

- Preparing Tractor

- Pallet Component Removal

- Installing Grille Guard (Optional)

- Installing Left and Right Mid-mounting Brackets

- 1. Lift right midmounting bracket (1) with overhead hoist. Fasten right midmounting bracket (1) to flywheel housing and tractor frame using HHCS M16 x 50MM (20) and M16 lockwashers (24).

- 2. Raise left midmounting bracket (2) with overhead hoist. Fasten left midmounting bracket (2) to flywheel housing using HHCS M16 x 50MM (20) and M16 lockwashers (24).

- 3. Install the back axle bars (3) on both sides of the tractor with HHCS M16 X 60MM (22), M16 spring washers (24) and M16 nut (26). Attaching them towards the center of the tractor in the back and towards the outside of the tractor in the front.

- 1. 55042 WDMT, MID MOUNT RH 1

- 2. 55043 WDMT, MID MOUNT LH 1

- 3. 55044 BACK AXLE BAR 2

- 4. 55045 WDMT, GRILLE GUARD 1

- 5. 55046 GRILLE GUARD BRACKET 1

- 6. 55047 PIN 1

- 7. 55048 SPRING 1

- 8. 54070 BRACKET - C/V 1

- 9. 54218 PIN, SPLIT 1

- 10. 49040-23 HEXB METRIC 8 - P1.25 - 50MM PL10 3

- 11. 701511C M8 PLAIN WASHER 3

- 12. 701611C M8 SPRING WASHER 3

- 13. 54133-3 M8 NUT 3

- 14. 49040-51 HEXB METRIC 10 - 1.5P -35MM PL10 2

- 15. 00755954 M10 SPRING WASHER 2

- 16. 54133-1 M10 NUT 2

- 17. 701513C M12 PLAIN WASHER 1

- 18. 49040-5 HEXB METRIC 16 - 2P - 50MM PL10 4

- 19. 701614C M14 SPRING WASHER 4

- 20. 701615C HEXB METRIC 16 - 2P - 50MM PL10 18

- 21. 49040-1 HEXB METRIC 16 - 2P - 60MM PL10 2

- 22. 49040-52 HEXB METRIC 16 - 2P X 60MM PL10 8

- 23. 55049 M16 DISC SPRING WASHER 2

- 24. 701615C M16 SPRING WASHER 26

- 25. 701515C M16 PLAIN WASHER 6

- 26. 54133-2 M16 NUT 10

- Attaching Hydraulic Block

- 1. Remove cover from tractor hydraulic area located under foot rest on right side of tractor. Align attaching holes in tractor with holes in hydraulic block. Install hydraulic block with O- rings in place using (4) bolts, lockwashers and O-rings. (Tw...

- 2. Install 90° pipe hydraulic elbow fitting in top front pressure port and point toward front of tractor.

- 3. Install straight pipe adapters into other two ports.

- Plumbing the Valve

- 1. Screw in three 90° hydraulic fittings into the power beyond tank, and pressure in the valve.

- 2. Screw in four straight fittings into the ports that control the lift and curl on top of the valve.

- 3. Screw in quick attaches into the straight fitting. Attach the dust caps to appropriate location shown in Figure 4.

- Attaching Valve to Tractor

- Plumbing Loader

- Installing Manual Canister to Boom Assembly

- Mounting Loader to Tractor

- Attaching Bucket to Loader

- Pre-Operation Check

- Hydraulics

- Connecting Quick Attach Device (Optional)

- Dismounting the Loader

- Mounting Loader

- RHINO 1625 LOADER

- OPERATION INSTRUCTIONS

- 1. Standard Equipment and Specifications

- 2. Operator Requirements

- 3. Tractor Requirements

- 4. Getting On and Off the Tractor

- 5. Starting the Tractor

- 6. Pre-Operation Inspection and Service

- 6.1 Tractor Pre-Operation Inspection/Service

- 7. Driving the Tractor and Loader

- 7.1 Starting the Tractor

- 7.2 Brake and Differential Lock Setting

- 7.4 Operating the Tractor and Loader

- 7.5 Operating the Loader

- 8. Loader Storage

- 9. Transporting the Tractor and Implement

- 9.1 Hauling the Tractor and Implement

- 10. Troubleshooting Guide

- Loader slow or will not lift Hydraulic oil too heavy. Change to proper oil.

- and/or dump

- Oil filter plugged. Clean or replace filter.

- Hydraulic pump worn. Repair or replace pump.

- Oil line restricted or leaking. Check all hoses and tubes for leaks,

- damage or restrictions. Replace

- damaged or restricted hoses or tube

- oil lines.

- Control valve does not shift Inspect, clean, repair or replace

- properly. valve.

- Air in hydraulic system. Cycle lift cylinders and bucket

- cylinders several times to free

- system of air.

- Cylinder leaks internally. Replace seals.

- Faulty relief valve (tractor). Clean and replace relief valve.

- Loader chatters or Air leak in pump inlet line. Check, tighten or replace inlet line.

- vibrates when raising

- or lowering

- Air in hydraulic system. Cycle lift and bucket cylinders.

- Oil level too low. Add oil as required.

- External leakage Damaged seals. Remove leaking component;

- replace seals.

- Pump noisy Inlet line restricted or leaking. Check for air leaks, restrictions or

- collapsed hose. Tighten or replace hose. Clean filter.

- Oil level too low. Add oil as required.

- Pump worn or damaged. Repair or replace pump.

- Excessive wear on bucket Bucket is riding on cutting edge Use boom “FLOAT” position or

- cutting edge instead of wear runners. bucket level indicator to ensure

- bucket rides on wear runners.

- MAINTENANCE SECTION

- Lubrication Schedule

- Daily Maintenance

- 1. Check fluid level of tractor hydraulic system before starting each day’s operation. If necessary, add hydraulic oil as recommended in your tractor operator’s manual.

- 2. After every four hours of operation, lubricate all sixteen grease fittings

- 3. After every ten hours of operation, check all hardware and tighten where required.

- 4. Replace hoses immediately if they are damaged by a cut or scrape, extruded at the fittings or leaking. Hydraulic oil leaks should be repaired promptly to avoid loss of oil and serious personal injury from escaping oil.

- Storage

- Proper Torque for Fasteners

- RHINO

- LIMITED WARRANTY

- 1. LIMITED WARRANTIES

- 1.01. Rhino warrants for one year from the purchase date to the original non-commercial, governmental, or municipal purchaser (“Purchaser”) and warrants for six months to the original commercial or industrial purchaser (“Purchaser”) that the ...

- 1.02. Manufacturer will replace for the Purchaser any part or parts found, upon examination at one of its factories, to be defective under normal use and service due to defects in material or workmanship.

- 1.03. This limited warranty does not apply to any part of the goods which has been subjected to improper or abnormal use, negligence, alteration, modification, or accident, damaged due to lack of maintenance or use of wrong fuel, oil, or lubricants, ...

- 1.04. Except as provided herein, no employee, agent, Dealer, or other person is authorized to give any warranties of any nature on behalf of Manufacturer.

- 2. REMEDIES AND PROCEDURES.

- 2.01. This limited warranty is not effective unless the Purchaser returns the Registration and Warranty Form to Manufacturer within 30 days of purchase.

- 2.02. Purchaser claims must be made in writing to the Authorized Dealer (“Dealer”) from whom Purchaser purchased the goods or an approved Authorized Dealer (“Dealer”) within 30 days after Purchaser learns of the facts on which the claim is based

- 2.03. Purchaser is responsible for returning the goods in question to the Dealer.

- 2.04. If after examining the goods and/or parts in question, Manufacturer finds them to be defective under normal use and service due to defects in material or workmanship, Manufacturer will:

- (a) Repair or replace the defective goods or part(s) or

- (b) Reimburse Purchaser for the cost of the part(s) and reasonable labor charges (as determined by Manufacturer) if Purchaser paid for the repair and/or replacement prior to the final determination of applicability of the warranty by Manufacturer.

- 2.05. Purchaser is responsible for any labor charges exceeding a reasonable amount as determined by Manufacturer and for returning the goods to the Dealer, whether or not the claim is approved. Purchaser is responsible for the transportation cost for...

- 3. LIMITATION OF LIABILITY.

- 3.01. MANUFACTURER DISCLAIMS ANY EXPRESS (EXCEPT AS SET FORTH HEREIN) AND IMPLIED WARRANTIES WITH RESPECT TO THE GOODS INCLUDING, BUT NOT LIMITED TO, MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

- 3.02. MANUFACTURER MAKES NO WARRANTY AS TO THE DESIGN, CAPABILITY, CAPACITY, OR SUITABILITY FOR USE OF THE GOODS.

- 3.03. EXCEPT AS PROVIDED HEREIN, MANUFACTURER SHALL HAVE NO LIABILITY OR RESPONSIBILITY TO PURCHASER OR ANY OTHER PERSON OR ENTITY WITH RESPECT TO ANY LIABILITY, LOSS, OR DAMAGE CAUSED OR ALLEGED TO BE CAUSED DIRECTLY OR INDIRECTLY BY THE GOODS INCLU...

- 3.04. NO ACTION ARISING OUT OF ANY CLAIMED BREACH OF THIS WARRANTY OR TRANSACTIONS UNDER THIS WARRANTY MAY BE BROUGHT MORE THAN TWO (2) YEARS AFTER THE CAUSE OF ACTION HAS OCCURRED.

- 4. MISCELLANEOUS.

- 4.01. Proper Venue for any lawsuits arising from or related to this limited warranty shall be only in Guadalupe County, Texas.

- 4.02. Manufacturer may waive compliance with any of the terms of this limited warranty, but no waiver of any terms shall be deemed to be a waiver of any other term.

- 4.03. If any provision of this limited warranty shall violate any applicable law and is held to be unenforceable, then the invalidity of such provision shall not invalidate any other provisions herein.

- 4.04. Applicable law may provide rights and benefits to purchaser in addition to those provided herein.

- TO THE OWNER/OPERATOR/DEALER