Raypak Versa 105B User Manual

Page 24

TUBE CLEANING PROCEDURE

Establish a regular inspection schedule, frequency

depending on local water condition and severity of

service. Do not let the tubes clog up solidly. Clean out

deposits over 1/16" in thickness.

The heater may be cleaned from the return header

side, without breaking pipe connections. It is prefer-

able, however, to remove both headers for better visibil-

ity through the tubes and to be sure the ground-up lime

dust does not get into the system.

Note that you do not remove the top panel or the

heat exchanger, generally.

After reaming, mount the wire brush in place of the

auger and clean out debris remaining in the tubes.

Another method is to remove the heat exchanger,

ream tubes and immerse heat exchanger in non-inhib-

ited de-scale solvent for severe scale build-up.

TUBE REPLACEMENT PROCEDURE

On Raypak units, tube replacement may be ef-

fected without rolling, as a temporary means of repair,

providing there are two or more tubes rolled in to act as

stays on the left and right sides. The "O" rings should

provide a seal up to 125 PSI working pressure. Use 3/

8" heavy duty reversible drill motor or large to power the

tube roller. If a reversible drill is not available, after

rolling the tube in, remove the drill motor and wrench out

the roller. A tube roller is available from the factory.

Shut gas and power off to the unit, close the system

off and drain the heater. Remove the draft diverter.

Remove the access panel and jacket top. Lift flue

collector off. Remove "V" baffles over tube(s) to be

replaced. If no pipe unions have been provided, use the

header as a union, remove the flange nuts off the inlet-

outlet header, break gas connection and slide heater

away from piping to allow room to work. Pull wedge

clips out of control wells and remove sensing bulbs.

Remove flange nuts of the return header and remove

header. Lift heat exchanger straight up and inspect "O"

ring seals at this time. Unless severed they are reus-

able. The tube may be cut out the a hacksaw or hammer

and chisel adjacent to both tube sheets, leaving studs

in the tube sheets. Then proceed to collapse studs in

the tube sheets with a chisel or screwdriver. Use

caution not to cut into the tube sheet. Replacement

tubes will have the fins stripped off longer on one end.

The long end is inserted into the opening of the tube

sheet first; then the short end is fitted through the

opposite tube sheet. If the tube ends become dented or

bent, straighten at least (4) inches back from the tube

and by means of a tapered punch.

Insert tube roller into tube opening up to stop

against tube, then push center rod in until roller is tight.

Be careful to keep replacement tube squared up 1/8"

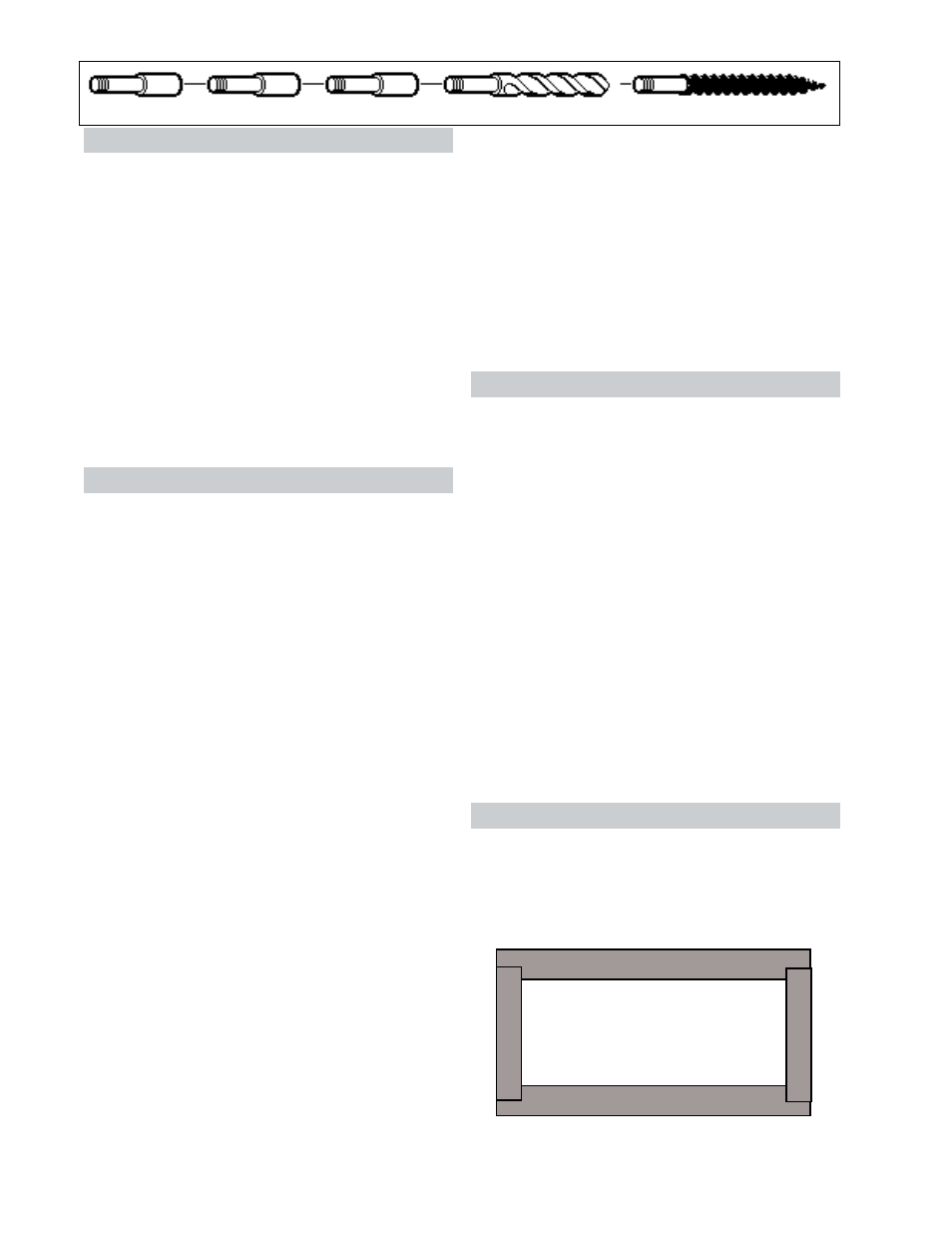

Extension Pieces (2)

Auger with Carbide Tip Wire Brush

24

outside each tube sheet. A loose tube will sometimes

pull toward the roller. Attach drill motor to tube roller,

holding it straight and level. Proceed to expand tube

until the tool begins to grab. At this point, 1/2" to 1"

should be exposed on the tool shank. Reverse drill

motor or wrench out by hand. Care should be exercised

to avoid applying excessive torque during rolling opera-

tion and to avoid thinning out any part of the tube wall

excessively over .015". Use same procedure at the

opposite end of the tube.

Apply line pressure test, and re-roll, if necessary

before re-assembly of the heater.

DESOOTING PROCEDURE

CAUTION: SOOT IS COMBUSTIBLE. EXERCISE

EXTREME CARE. NEVER USE A WIRE BRUSH.

Soot can clog areas between fins and cause even-

tual tube failure. Any sign of soot at the base of the

burners or around the outer jacket indicates a need for

cleaning.

1. Disconnect top portion of unit. (See heat

exchanger

removal procedure steps 1 through 6).

2. Remove burner tray (See burner tray removal

procedure.)

3. Take a garden hose and wash heat exchanger,

making sure soot is removed completely from be-

tween fins. Avoid excessive water against refrac-

tory.

NOTE: In extreme cases it may be necessary to re-

move the heat exchanger completely for cleaning. The

simplest method is steam cleaning at the local car

wash. DO NOT WIRE BRUSH.

COMBUSTION CHAMBER REMOVAL

1. Remove heat exchanger (See heat exchanger

removal procedure).

2. Lift up and remove front and rear refractory shield.

3. Remove refractory panels.

4. Reverse above procedure to re-install.

Fig . # 8155.0s

Refactory Panel Top View

Fig. # 8154.0