Raypak Versa 105B User Manual

Page 16

EXTERNAL AUXILIARY BYPASS VALVE

(Where required)

An auxiliary bypass valve should be used when flow

rates exceed 115 GPM (usually a high performance

pump size larger than 2 HP will exceed this flow rate).

This valve is required to complement the function of the

automatic bypass valve, particularly when starting the

heater in winter or early spring when the spa or pool

temperature is down below 55°F. It also serves to

eliminate needless pressure drop through the heater and

accompanying reduction in the flow rate to the spa jets,

etcetera.

From Heater To Heater

To Pool

From Pool

Auxiliary Bypass Valve (do not use gate valve)

AUXILIARY BYPASS VALVE ADJUSTMENT

To set bypass: With clean filter, adjustment is made

by feeling the inlet and outlet pipes at the heater. Outlet

pipes should be slightly warmer than inlet and comfort-

able to the touch. If pipe is hot, close bypass; if cold, open

bypass.

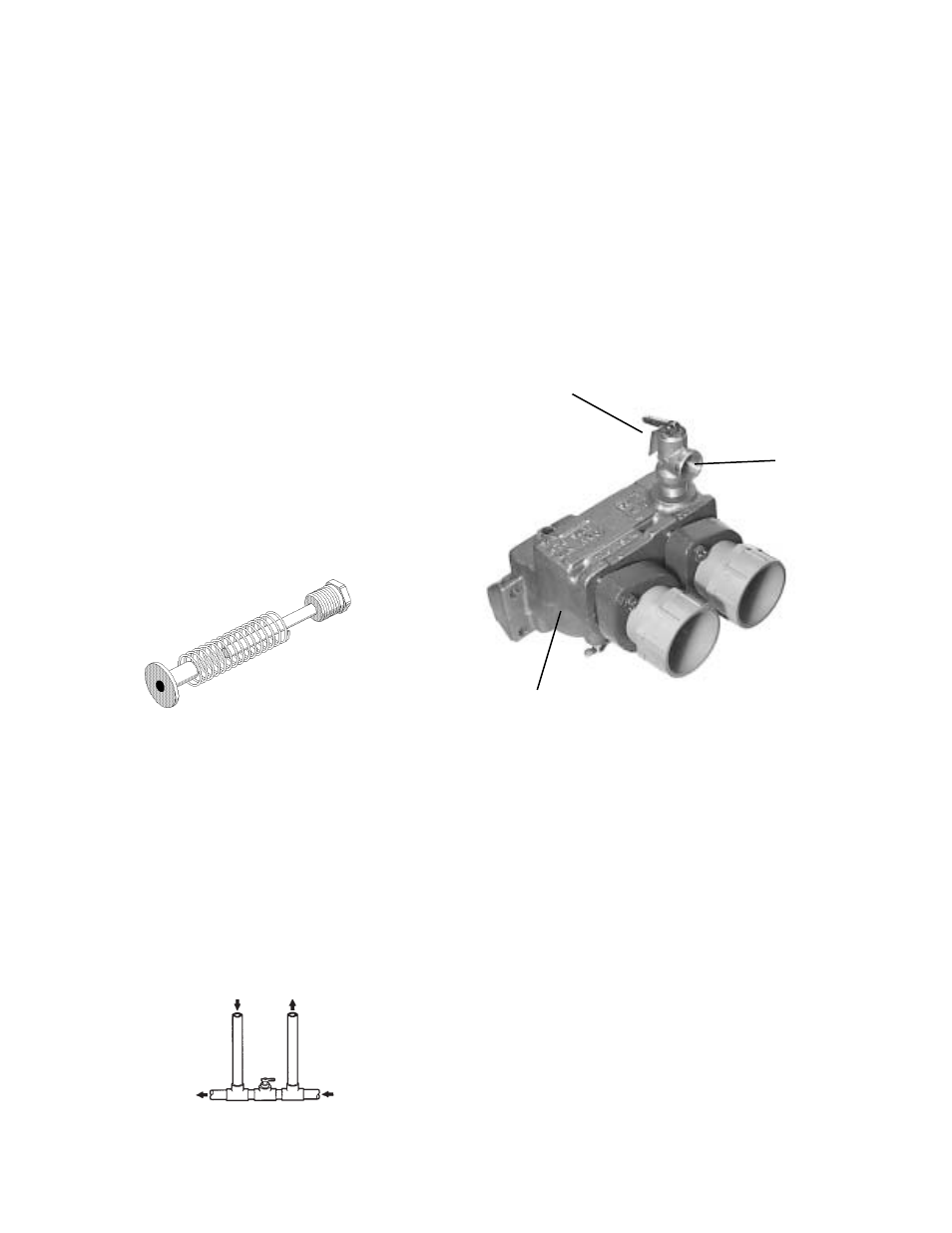

INTERNAL AUTOMATIC BY-PASS VALVE

A built-in automatic by-pass valve is provided in the

in/out header. The internal by-pass valve automatically

responds to changes in water pressure in the piping

system. Proper amount of water flow is maintained

through the heater under varying pressures dictated by

the conditions of the pump and filter.

Fig. # 8078.0

PRESSURE RELIEF VALVE INSTALLATION

To conform to local building codes, it may be neces-

sary to install a pressure relief valve. A 3/4" pressure relief

valve having a capacity equal to BTU/HR output of the

model to be installed is recommended for this appliance.

A 3/4" NPT connection is provided in the inlet/outlet

header for installation of a pressure relief valve. The valve

shall be installed in a vertical position.

PRESSURE RELIEF

VALVE

PRV

DISCHARGE

CONNECTION

INLET/OUTLET HEADER

Fig. # 8095.0

NOTE: To avoid water damage or scalding due to valve

operation, drain pipe must be connected to valve outlet

and run to a safe place of discharge. Drain pipe must be

the same size as the valve discharge connection

throughout its entire length and must pitch downward

from the valve. No shut-off valve shall be installed

between the relief valve and the drain line. Valve lever

should be tripped at least once a year to ensure that

waterways are clear.

Fig. # 8150.

NOTE: High chemical concentration from feeders and

chlorinators that are out of adjustment will cause very

rapid corrosion to the heat exchanger in the heaters.

Such damage is not covered under the warranty.

UNITHERM GOVERNOR OPERATION

(PREMIUM BRONZE HEADERS ONLY)

The patented Unitherm Governor is a thermostatic

mixing valve specifically designed to maintain constant

heater internal temperature between 105° - 115°F despite

continually changing flow rates from the filter and chang-

ing pool temperatures. This narrow range is needed to

prevent damaging condensation on the burners which will

occur if the heater runs for any length of time below 100°F.

It is also needed to inhibit scale formation in the tubes by

maintaining temperatures well below accelerated scaling

temperatures.

16