Plumbing for water connections – Raypak Versa 105B User Manual

Page 15

PLUMBING FOR WATER CONNECTIONS

LOCATION

The VERSA heater requires water flow and positive

pressure to fire and operate properly. It must therefore be

installed downstream of the discharge side of the filter

pump. A typical installation is plumbed as follows:

1. The inlet side of the filter is plumbed directly to

the discharge side of the filter pump;

2. The outlet side of the filter is then plumbed to

the inlet of the heater; and

3. The outlet of the heater is plumbed to the

return line to the pool or spa. The pump, filter

and heater are thus plumbed in series.

Plumbing from the heater back to the pool must not have

any valves or restriction that could prevent flow when the

pump is operating. To do so will void the warranty.

FLOW RATES

MIN.GPM: 20, MAX.GPM: 115*

*When flow rates exceed 115 GPM an external auxiliary

bypass valve is required. See External Auxiliary Bypass

Valve section for details.

15

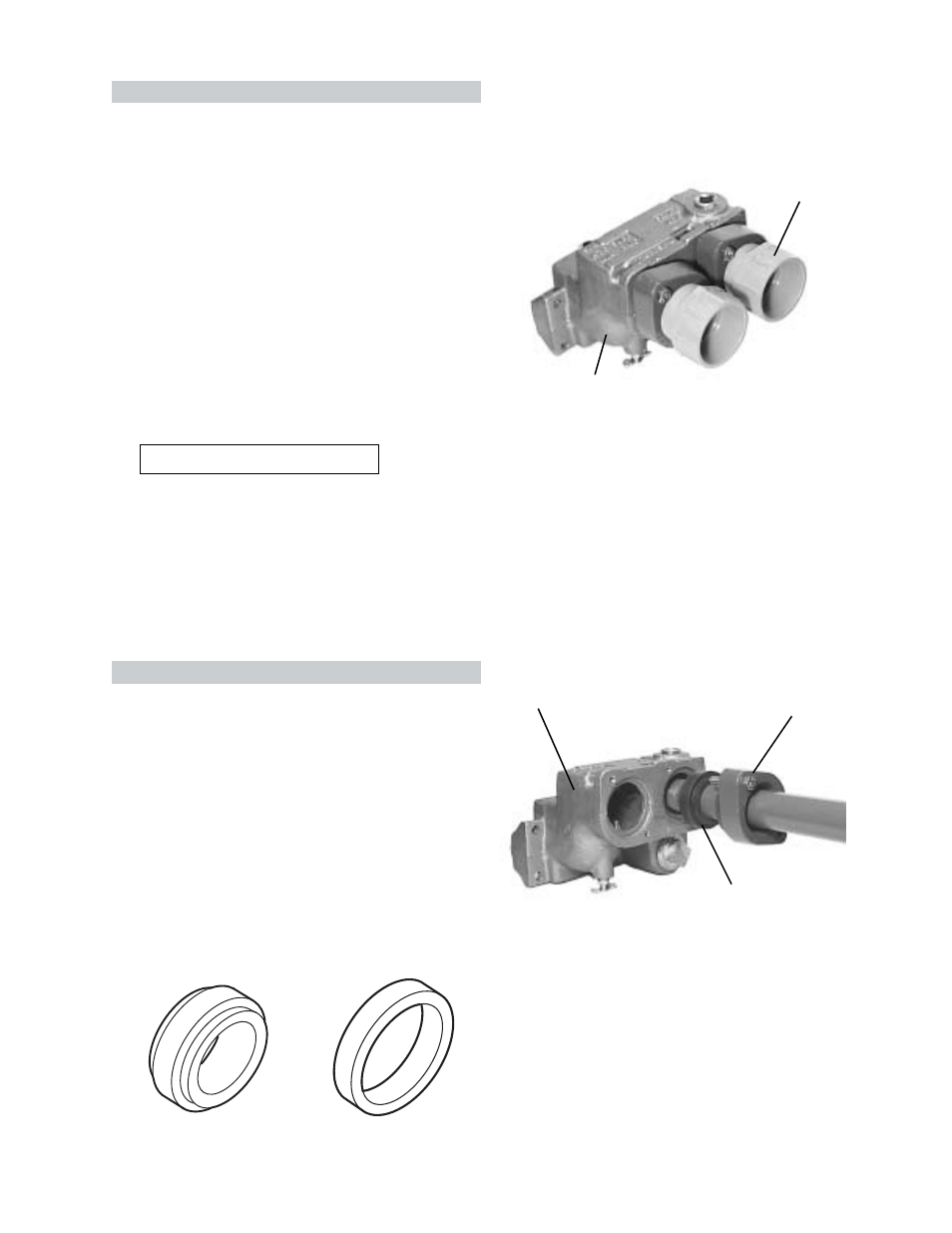

COMPANION FLANGE CONNECTIONS

DO NOT use petroleum base assembly fluids (such

as Petroleum Jelly or lubricating oil). If assembly lube is

required use a silicone base such as Amoral etc.

PREMIUM BRONZE HEADER

The inlet/outlet single header flanges are designed for four

type of water connections. There are two sets of flange

gaskets supplied with your header; one set installed,

between flanges and in/out header, and the other set

shipped loose in the unit. Use the appropriate gasket

design, for all your heater connections.

GASKET DESIGN #1: (Factory Installed) Accepts

1-1/2" copper tube or 1-1/4" galvanized pipe as a slip

connections.

GASKET DESIGN #2: (Loose in a Bag) Accepts 2"

copper tube as a slip connection. The flange is threaded

for 2" screw in pipe connections. Also used with the 2"

CPVC adapters.

#1

#2

Fig. #8095.1

Fig. # 8097.1

INLET/OUTLET HEADER

AUTOMATIC CHLORINATORS AND CHEMICAL

FEEDERS

All chemicals must be introduced and completely

diluted into the pool or spa water before being circulated

through the heater. Do not place chlorine tablets or

bromine sticks in the skimmer. High chemical concen-

trations will result when the pump is not running (i.e.

overnight).

Chlorinators must feed downstream of the heater and

have an anti-siphoning device to prevent chemical back-

up into the heater when the pump is shut off.

Fig # 9272

FLANGE GASKET

HEADER FLANGE

Fig # 9273

CAUTION: NEVER install PVC directly in header

flanges. Use the 2" CPVC adapter (supplied by others).

NOTE: If 2" piping is used in the heater, this piping must

be anchored (copper) or screwed into the flange (metal)

if operating pressures above 30 PSI are encountered.

CAUTION: Never install PVC directly in header flanges.

The initial connection must be made with high

temperature materials such as CPVC or copper.

For IID pilots: PVC may be utilized immediately after the

initial connections.

For Standing pilots: Copper or high temperature CPVC

pipe and two elbows are required between the heater and

the PVC connections (heat sinks not supplied).

High temperature 2" plastic pipe (CPVC) may be

threaded directly into the header flanges. This is not the

same as the Schedule 80 PVC pipe which is also colored

gray. PVC may be used immediately after the CPVC

adapters.

INLET/OUTLET HEADER

2" CPVC Adapters

(supplied by others)