Raypak D-2 POWER VENT 206A User Manual

Page 8

8

INSTALLATION (Continued)

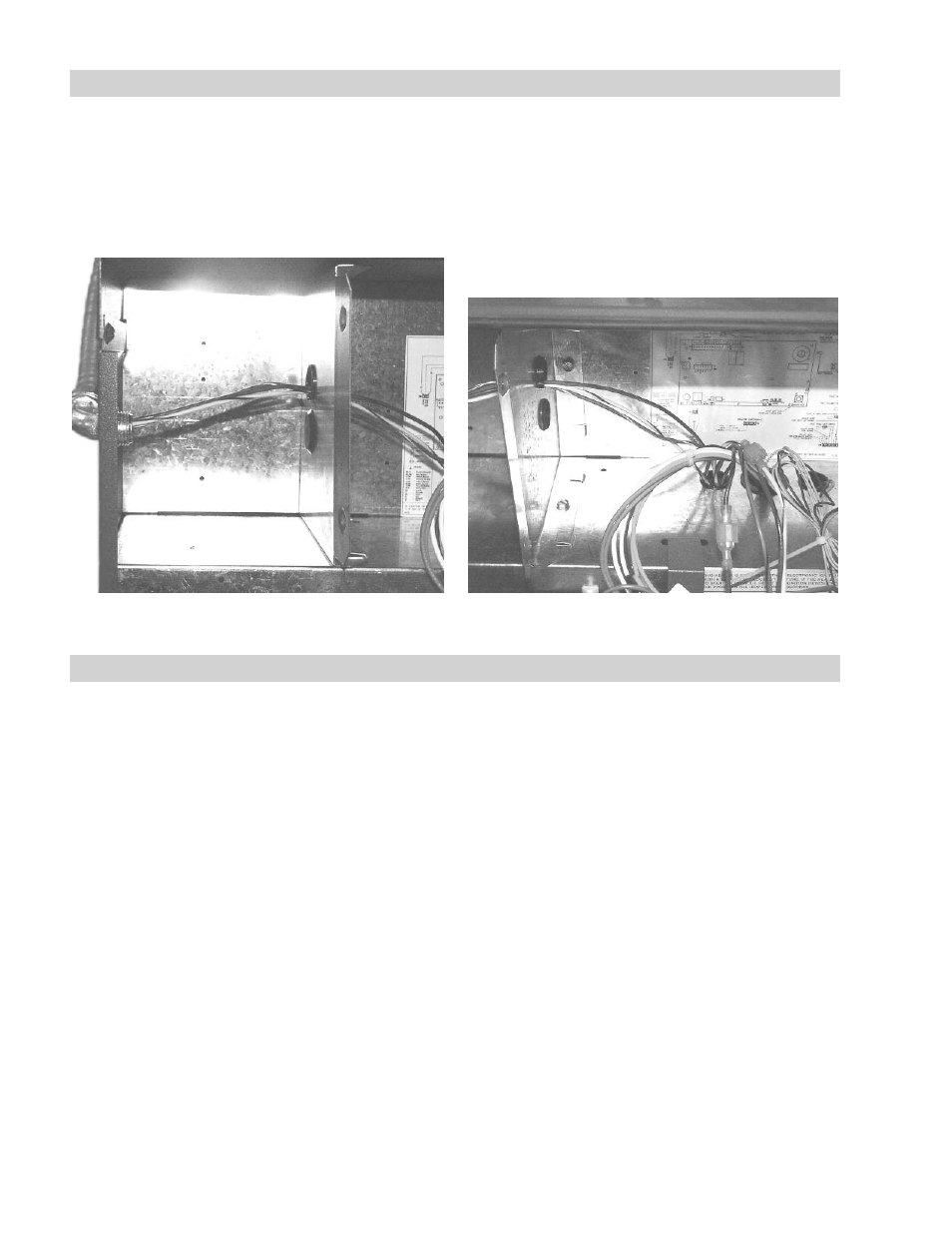

19. Route the 24 VAC harness through the 7/8” grommet, See Fig. 17.

20. Continue to route the harness down through any available grommet hole. See Fig. 18.

21. Wire the harness along with the installed gas valve harness per the wiring diagram.

22. Reinstall the (4) Phillips screws that hold the control panel to the heater. See Fig. 15.

23. Place the front door back onto the heater. Refer to Fig. 1.

VENTING

The D-2 Power Vent operates with a positive vent static pressure and with a vent gas temperature that prevents

excessive condensate production in the vent, and as such, is a CATEGORY III appliance.

The total length of horizontal run shall not exceed an equivalent length of 100 ft including the termination cap.

For all cases, each 90° elbow reduces the maximum horizontal vent run by 10 ft and each 45° elbow reduces

the run by 5 ft. The vent must be installed properly to prevent the flue gas leakage within the heater. The vent

pipe must be suitable for use with Category III Appliances which have flue gas temperatures of less than 400°F.

Care must be taken during the assembly to ensure that all joints are properly sealed.

For appliances installed in extremely cold climates, it is recommended that:

a) The vent be installed with a slight upward slope of not more than 1/4” per foot of horizontal run to the

vent terminal. In this case, an approved condensation trap must be installed per applicable codes.

b) The vent be insulated through the length of the horizontal run.

The exit terminal of the D-2 Power Vent shall not be less than 7 ft above grade where located adjacent to pub-

lic walkways. It must also be at least 3 ft above any forced air inlet located within a 10 ft radius.

Fig 17

Fig 18