Important warning, Using current limiting as protection, Control loop description – RoboteQ AX2850 User Manual

Page 93

AX2550 Motor Controller User’s Manual

93

Using Current Limiting as Protection

Important Warning

Limit switches must be used when operating the controller in Position Mode. This

will significantly reduce the risk of mechanical damage and/or injury in case of dam-

age to the position sensor or sensor wiring.

Using Current Limiting as Protection

It is a good idea to set the controller’s current limit to a low value in order to avoid high cur-

rent draws and consequential damage in case the motor does not stop where expected.

Use a value that is no more than 2 times the motor’s draw under normal load conditions.

Control Loop Description

The AX2550 performs the Position mode using a full featured Proportional, Integral and Dif-

ferential (PID) algorithm. This technique has a long history of usage in control systems and

works on performing adjustments to the Power Output based on the difference measured

between the desired position (set by the user) and the actual position (captured by the

position sensor).

Figure 61 shows a representation of the PID algorithm. Every 16 milliseconds, the control-

ler measures the actual motor position and substracts it from the desired position to com-

pute the position error.

The resulting error value is then multiplied by a user selectable Proportional Gain. The

resulting value becomes one of the components used to command the motor. The effect

of this part of the algorithm is to apply power to the motor that is proportional with the dis-

tance between the current and desired positions: when far apart, high power is applied,

with the power being gradually reduced and stopped as the motor moves to the final posi-

tion. The Proportional feedback is the most important component of the PID in Position

mode.

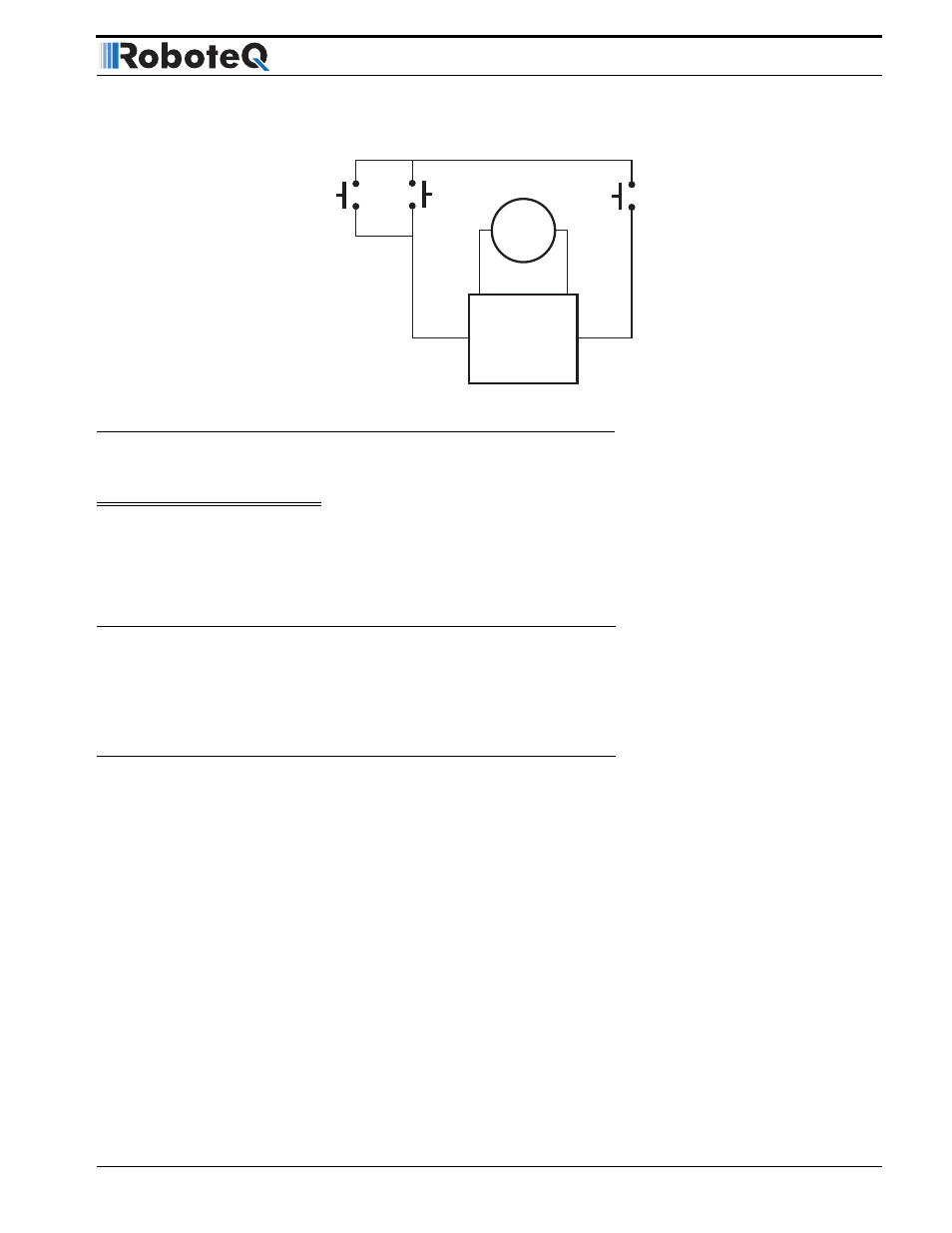

Motor

SW1

SW2

Manual

Emergency

Stop Switch

Emergency Stop Input

Ground

Controller

FIGURE 60. Safety limit using AX2550’s Emergency Stop input