Parker Products OEM650X User Manual

Page 36

29

OEM650/OEM650X • INSTALLATION

connect a single-ended, incremental, optical encoder to the

OEM650X. When an encoder is used, the following functions will be

added to the system:

❏ Encoder referenced positioning

❏ Encoder position servoing

❏ Motor stall detection

❏ Higher accuracy homing function

❏ Multi-axis stop (also available without an encoder—see FSF in

command reference)

Encoder Inputs A, B, Z (Signals 17-19)

The OEM650X has three

dedicated inputs for use with a

single ended incremental

encoder. These inputs in

conjunction with the FS com-

mands will determine the

encoder functionality.

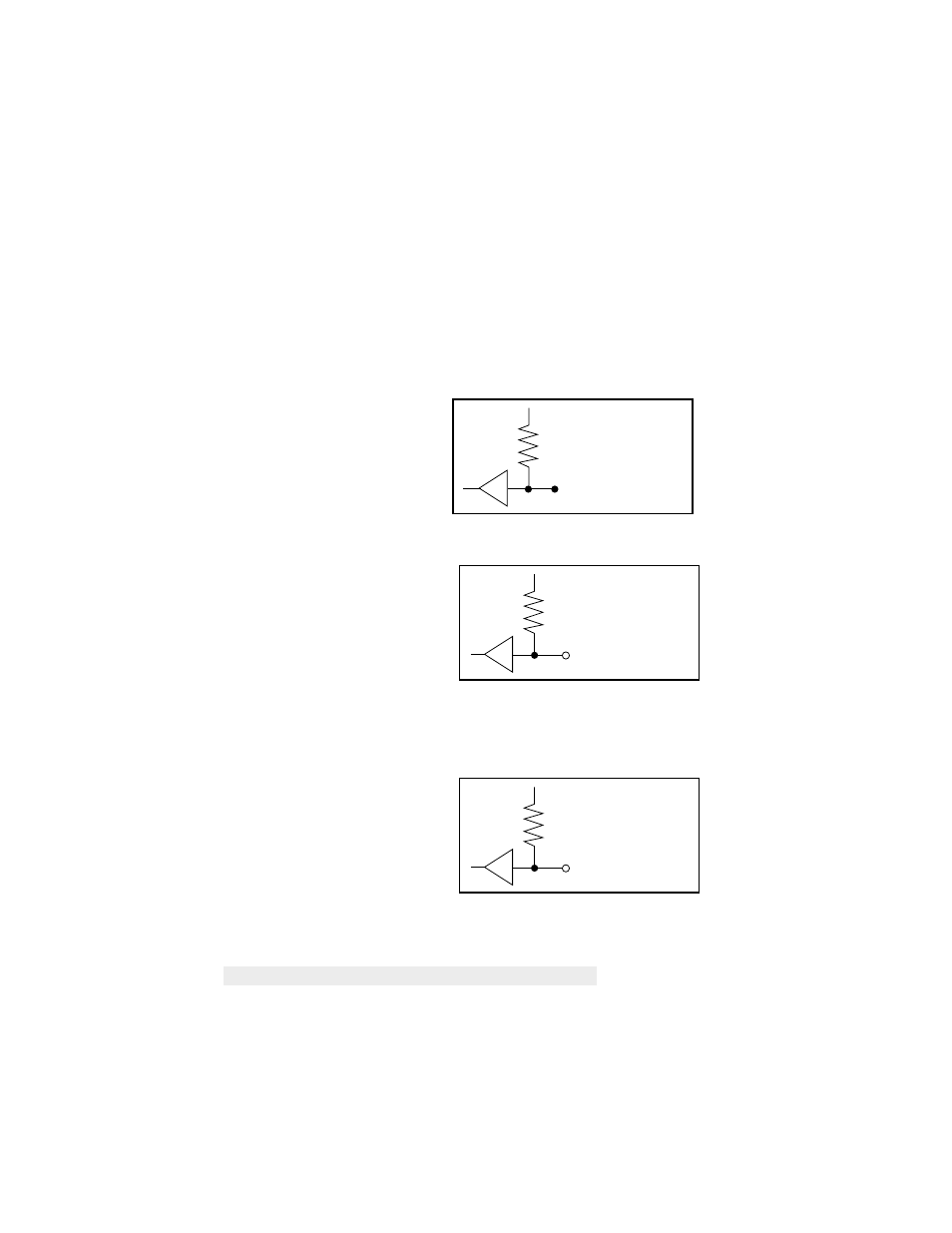

Trigger Inputs #1 - #3 (Signals 20 - 22)

The OEM650X has three dedi-

cated Trigger inputs. These

inputs are pulled up internally.

These inputs are used with the

Trigger (TR) command to control

the OEM650X's trigger function.

The figure represents a typical

configuration of these inputs.

Address Signals #1 - #3 (Signals 23 - 25)

The OEM650X has three dedicated address inputs that allow you to

specify a unique address for each OEM650X in your configuration.

Units may be assigned a valid

address from 1 to 8. Each unit

in the configuration must have a

unique address. The default

address is 8 (all three inputs are

internally pulled up. The address

inputs are read only during

power-up and when Restart (Z) commands are issued. Use the

matrix below to assign unique address values. (Refer to the

# command for more information.)

Address #

8

7

6

5

4

3

2

1

Address #1

Ш

1

Ш

1

Ш

1

Ш

1

Address #2

Ш

Ш

1

1

Ш

Ш

1

1

Address #3

Ш

Ш

Ш

Ш

1

1

1

1

• Maximum low-level input: 0.8V

(Sinks 1.2 mA)

• Minimum high-level input: 2V

+5V

4.75k

HCT541

• Maximum low-level input: 0.8V

(Sinks 1.2 mA)

• Minimum high-level input: 2V

+5V

4.75k

HCT244

• Maximum low-level input: 0.8V

(Sinks 1.2 mA)

• Minimum high-level input: 2V

+5V

4.75k

HCT541