The tests detailed in, Table f.2, Troubleshooting & repair – Lincoln Electric INVERTEC V250-S User Manual

Page 49: Input rectifier test (continued)

F-17

TROUBLESHOOTING & REPAIR

F-17

6. If the Input Rectifier does not meet

the acceptable readings outlined in

Table F.2. the component may be

faulty. Replace.

Note: Before replacing the Input

Rectifier(D9) check the input

power switch (S1) and perform

the

Test. Also check for leaky or

faulty filter capacitors.

7.

When installing a new Input

Rectifier, torque the mounting nuts to

44IN-LBS. A thin coating of Dow

Corning 340 Heat Sink Compound

(Lincoln E1868) is recommended.

Torque the lead terminals to 31IN-

LBS. See

8. If the Input Rectifier is good be sure

to reconnect leads #207, #207A and

#209 to the correct terminals and

torque to 31IN-LBS. See wiring dia-

gram and Figure F.2.

INPUT RECTIFIER TEST (continued)

INVERTEC V250-S

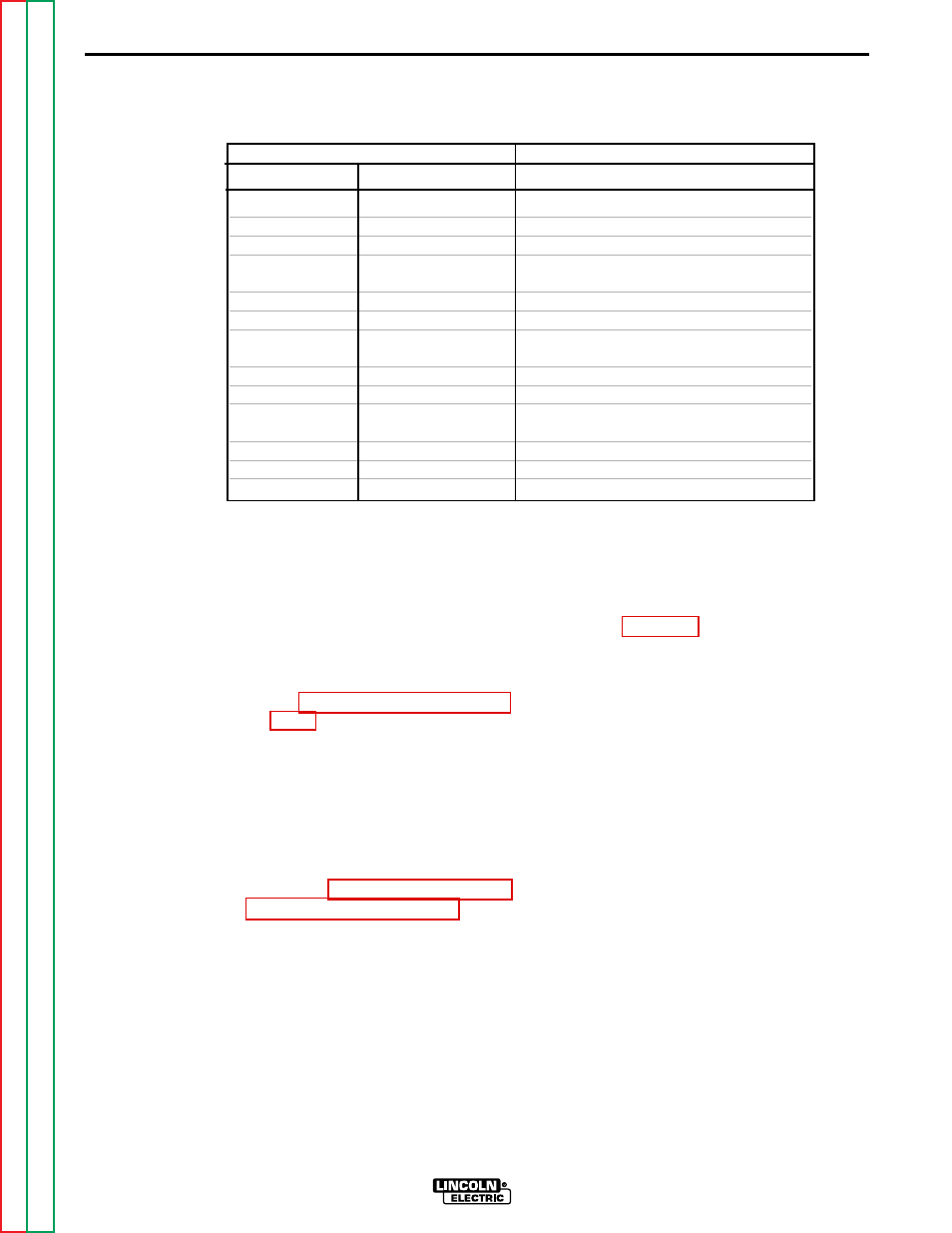

TEST POINT TERMINALS

ANALOG METER X10 RANGE

+ Probe

- Probe

Acceptable Meter Readings

A

207

Greater than 1000 ohms

B

207

Greater than 1000 ohms

C

207

Greater than 1000 ohms

A

209

Less than 100 ohms

B

209

Less than 100 ohms

C

209

Less than 100 ohms

207

A

Less than 100 ohms

207

B

Less than 100 ohms

207

C

Less than 100 ohms

209

A

Greater than 1000 ohms

209

B

Greater than 1000 ohms

209

C

Greater than 1000 ohms

TABLE F.2 Input Rectifier Test Points