Lochinvar 000 - 500 User Manual

Page 31

o. Check “V” baffles on top of the heat

ex chang er. Remove and clean if necessary.

p. Remove soot from the heat exchanger with a stiff

bristle brush. Soot may also be re moved from the

heat exchanger by washing thoroughly with

detergent and water. Remove the heat exchanger

before using water for cleaning. Rinse thoroughly

and dry before re-installing. Use a vacuum to

remove loose soot from surfaces and in

ner

chamber.

q. Remove the heat exchanger (HEX) filler bracket

(FIG. 38A).

r. The heat exchanger can be removed by sliding

towards the front of the appliance. Once the

heat exchanger is removed from the ap pli ance,

a garden hose can be used to wash the tubes to

ensure that all soot is removed from the heat

exchanger surfaces.

s. Ensure that all burner ports are cleaned to

remove any soot. See Inspection and Cleaning

Procedure, page 30.

t. Carefully re-install the heat exchanger, “V”

baffles, jacket panels, and wires.

u. Reassemble all gas and water piping. Test for

gas leaks.

v. Cycle the appliance and check for prop

er

operation.

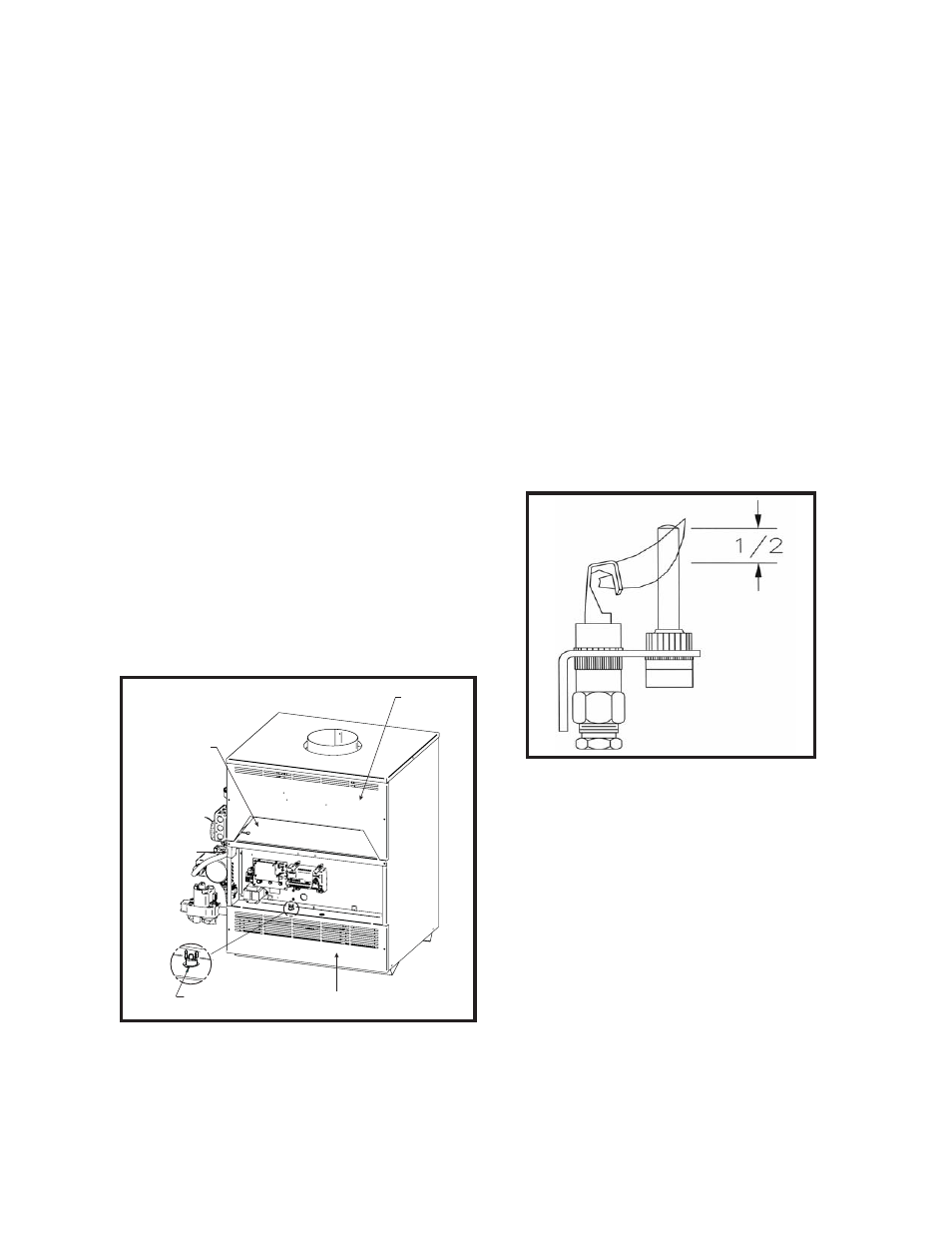

FIG. 38A Outer Air Deflector and HEX Filler Bracket

5. Water Circulating Pump: Inspect pump ev

ery 6

months and oil if required. Use SAE 30

non-detergent oil or lubricant specified by pump

man u fac tur er.

6. Keep appliance area clear and free from

com

bus

ti

ble materials, gasoline and other

flammable vapors and liquids.

7. Check frequently to be sure the flow of com bus -

tion and ventilation air to the boiler is not

obstructed.

8.

Inspection of Heat Exchanger Waterways:

Appliances operated in hard water areas should

have periodic inspections of the tubes to be sure

that no sediment or scale accumulates on the heat

transfer sur fac es. Inspection plugs are located at

both ends of the heat exchanger. In spec tion plugs

should be removed and tubes inspected at the end

of the first 45 days of operation and again at the

end of 90 days of operation. If no scale

accumulation is ob served, inspections can be made

at the end of each six months of op er a tion.

9. Pilot Flame Adjustment Procedure - The pi

lot

flame should envelop 3/8" to 1/2" (10 to 13mm) of

the tip of the thermocouple (see Figure 38B).

FIG. 38B Pilot Flame on Thermocouple

a. Remove pilot adjustment cover screw on gas

valve. See Gas Valve Illustrations in the

Lighting Instructions section for lo

ca

tion of

cover screw.

b. Turn inner adjustment screw clock

wise to

decrease or counterclockwise to increase pilot

flame.

c. If difficulty is experienced in ad

just

ing the

pilot flame, a tee may be installed in the pilot

line from the gas valve to the pilot burn er.

d. Replace pilot adjustment cover screw on valve.

Tighten firmly after adjustment to prevent gas

leakage.

31

"

FLAME ROLL-OUT SWITCH /

INTERLOCK SWITCH

LOWER FRONT

JACKET PANEL

UPPER FRONT

JACKET PANEL

OUTER AIR

DEFLECTOR

HEX FILLER

BRACKET