Lochinvar 000 - 500 User Manual

Page 14

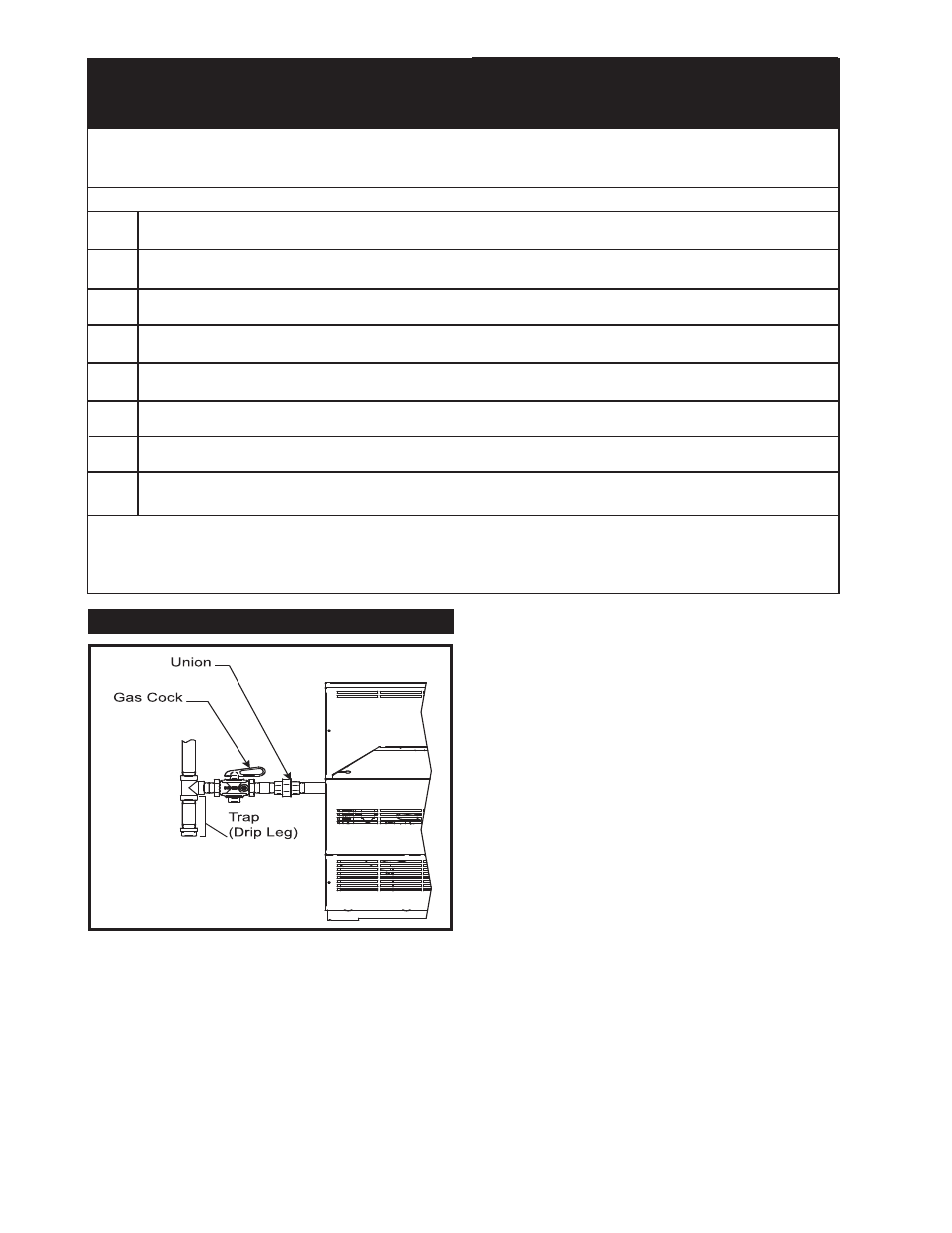

FIG. 16 Gas Line Connection

All gas connections must be made with pipe joint

com pound resistant to the action of liquefied pe tro leum

and natural gas. All piping must comply with local

codes. Tubing installations must com ply with ap proved

standards and practices. Reference Figure 16 for a

typical installation.

Install Piping to Control

1.

The gas line should be a separate line direct

from the meter unless the existing gas line is of

sufficient capacity. Verify pipe size with your gas

sup pli er.

2.

Use new, properly threaded black iron pipe free

from chips. If tubing is used, make sure the ends

are cut squared, deburred and clean. All tubing

bends must be smooth and without deformation.

Avoid flexible gas connections. Internal diameter

of flexible lines may not provide proper volume of

gas.

3.

Run pipe or tubing to the gas valve or manifold

inlet. If tubing is used, obtain a tube to pipe

coupling to connect the tubing to the gas valve

or man i fold inlet.

4.

Thread pipe the proper amount for insertion into gas

valve or manifold inlet as shown in Table H.

DO NOT OVER TIGHTEN. Over tightening may

result in damage to the gas valves. Valve distortion

or malfunction may result if the pipe is inserted too

deeply into the gas valve.

5.

Apply a moderate amount of good quality pipe

compound (DO NOT use Teflon tape) to pipe

only, leaving two end threads bare.

6.

Remove seal over gas valve or manifold inlet.

7.

Connect pipe to gas valve or manifold inlet. Use

wrench to square ends of the gas valve (FIG. 17).

14

Nominal

Iron Pipe

Length of Pipe in Straight Feet

Size, Inches

10

20

30

40

50

60

70

80

90

100

125

150

175

200

3/4

369

256

205

174

155

141

128

121

113

106

95

86

79

74

1

697

477

384

328

292

267

246

226

210

200

179

164

149

138

1 1/4

1,400

974

789

677

595

543

502

472

441

410

369

333

308

287

1 1/2

2,150 1,500

1,210

1,020

923

830

769

707

666

636

564

513

472

441

2

4,100 2,820

2,260

1,950

1,720

1,560

1,440

1,330

1,250 1,180

1,100

974

871

820

2 1/2

6,460 4,460

3,610

3,100

2,720

2,460

2,310

2,100

2,000 1,900

1,700

1,540 1,400

1,300

3

11,200 7,900

6,400

5,400

4,870

4,410

4,000

3,800

3,540 3,300

3,000

2,720 2,500

2,340

4

23,500 16,100 13,100 11,100 10,000

9,000

8,300

7,690

7,380 6,870

6,150

5,640 5,130

4,720

Maximum Capacity of Pipe in Thousands of BTU’s per hour for gas pressures of 13.5 Inches Water Col umn

(0.5 PSIG) or less and a pressure drop of 0.5 Inch Water Column (Based on the calorific value of Natural Gas,

1025 Btu/ft

3

@ 0.60 Specific Gravity)

TABLE - H

MULTIPLE APPLIANCE INSTALLATIONS

GAS PIPING SIZE CHART

GAS PIPING