Lochinvar 000 - 500 User Manual

Page 12

Verify that the appliance is supplied with the type gas

spec i fied on the rating plate. This appliance is orificed

for operation up to 2000 feet altitude. The ap pli ance

will be derated 4% per 1000 feet above 2000 feet el e va -

tion. Consult the factory for installations above 2000

feet elevation. Field conversions for operation at high

altitude must be performed by certified per son nel only.

The appliance will be marked to indicate suitability for

high al ti tude operation.

GAS SUPPLY PRESSURE: Measured at the inlet

pres sure tap located upstream of the combination gas

valve(s) see Figures 20 - 22, page 17.

Maximum inlet gas pressure must not exceed the val ue

specified. Minimum value listed is for the purposes of

input adjustment.

MANIFOLD PRESSURE: Measured at the pres sure

tap on the downstream side of the com

bi

na

tion gas

valve(s) (see Figures 20 - 22 on page 17). The gas

regulator settings for single stage and two stage

operation are factory set to supply proper manifold

pressure for normal operation. To check manifold

pressure, see Manifold Ad just ment Procedure. Do not

increase manifold pressure beyond spec

i

fied

pressure settings shown below in Table D.

1.

The appliance must be disconnected from the

gas supply piping system during any pressure

testing of that system at a test pressure in

excess of 1/2 PSIG (3.5kPa).

2. The appliance must be isolated from the gas

supply piping system by closing a manual

shutoff valve during any pressure testing

of the gas supply piping system at test

pressures equal to or less than 1/2 PSIG

(3.5kPa).

3.

The appliance and its gas connection must

be leak-tested before placing it in operation.

1.

Safe operation of the appliance requires

properly sized gas supply piping. See data

in Table E.

2.

Gas pipe size may be larger than appliance

gas connection.

3.

Installation of a union is suggested for ease

of service, see Figure 16 on page 14.

4. Install a manual main gas shutoff valve,

outside of the appliance gas connection and

before the gas valve or manifold connection,

when local codes require.

5.

A trap (drip leg) MUST be provided by the

installer in the inlet of the gas connection to the

appliance, see Figure 16 on page 14.

6.

The combination gas valve has an integral

vent lim

it

ing device and does not require

venting to atmosphere, outside the building.

12

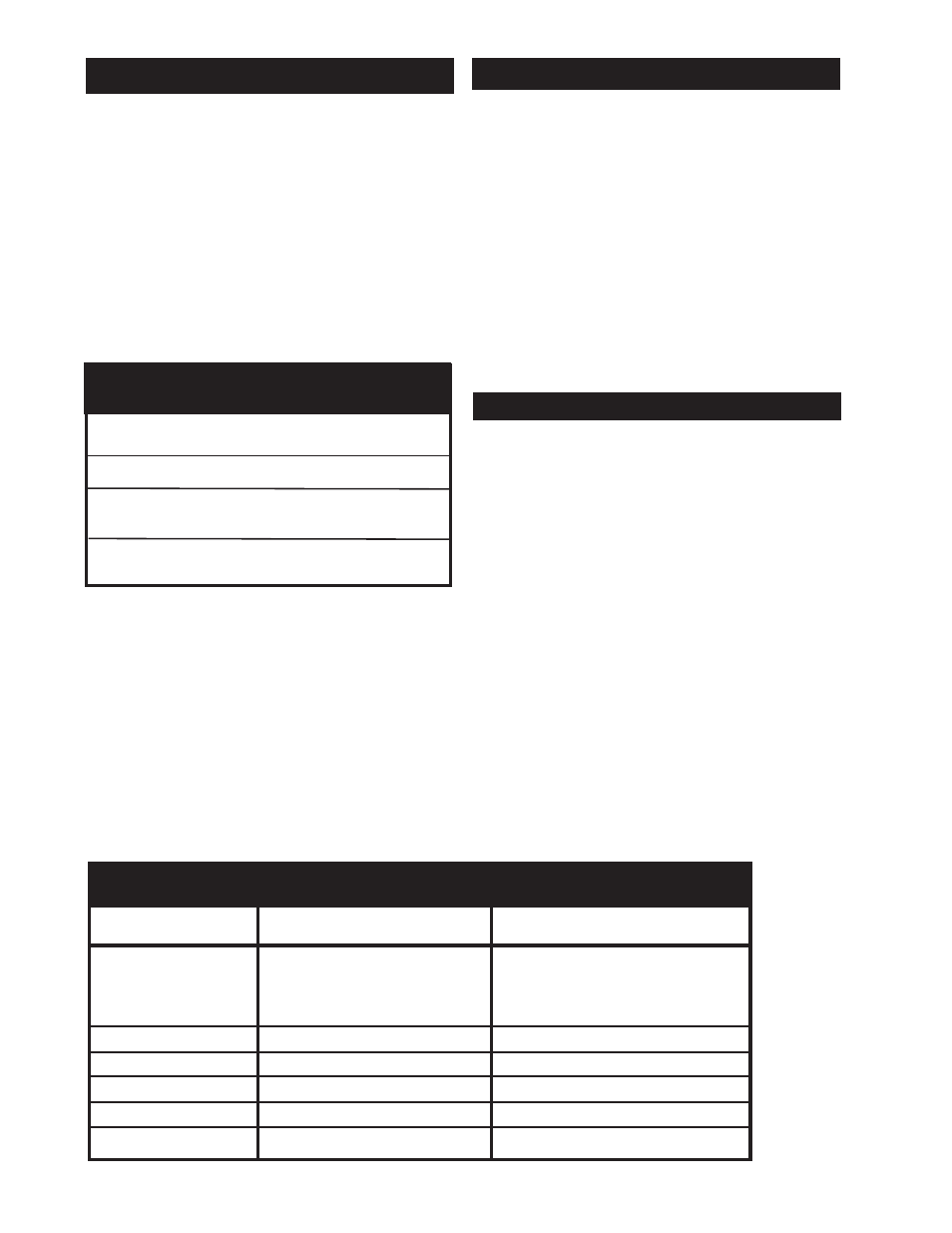

GAS PRESSURE TEST

GAS CONNECTION

GAS SUPPLY

Nat. Gas LP Gas

Max. (Inches Water Column) 10.5 13

Min. (Inches Water Column) *4.5 11

Min. (Inches Water Column) **5.0 11

*Models 45,000 - 360,000 Btu/hr Only

**Models 399,999 - 500,000 Btu/hr Only

TABLE - C

GAS SUPPLY PRESSURE

Single and Two-Stage

Two Stage

Btu/hr Full or High Fire Settings

Low Fire Settings

Input Gas

Natural Gas L.P. Gas

Natural Gas

L.P. Gas

45,000

3.5" 10"

0.9"

2.5"

75,000

2.4"

7"

0.9"

2.5"

90,000 - 180,000

3.5"

10"

0.9"

2.5"

199,999

2.9"

7.5"

0.9"

2.5"

215,000 - 399,999

3.5"

10"

0.9"

2.5"

500,000

3.5"

10" (two valves)

N/A

N/A

TABLE - D

MANIFOLD PRESSURE