Maintenance, Address reported problems, Inspect boiler area – Lochinvar 1 User Manual

Page 58: Inspect boiler interior, Clean condensate trap, Check all piping for leaks

58

Installation & Operation Manual

11

Maintenance

Follow the service and maintenance procedures given throughout this manual and in component literature

shipped with the boiler. Failure to perform the service and maintenance could result in damage to the boiler

or system. Failure to follow the directions in this manual and component literature could result in severe

personal injury, death, or substantial property damage.

The boiler should be inspected annually only by a qualified service technician. In addition, the maintenance

and care of the boiler designated in Table 11A and explained on the following pages must be performed to

assure maximum boiler efficiency and reliability. Failure to service and maintain the boiler and system could

result in equipment failure.

Electrical shock hazard – Turn off power to the boiler before any service operation on the boiler except as

noted otherwise in this instruction manual. Failure to turn off electrical power could result in electrical shock,

causing severe personal injury or death.

Address reported problems

1. Inspect any problems reported by the owner and correct

before proceeding.

Inspect boiler area

1. Verify that boiler area is free of any combustible materials,

gasoline and other flammable vapors and liquids.

2. Verify that air intake area is free of any of the contaminants

listed in Section 1 of this manual. If any of these are

present in the boiler intake air vicinity, they must be

removed. If they cannot be removed, reinstall the air and

vent lines per this manual.

Inspect boiler interior

1. Remove the front access cover and inspect the interior of

the boiler.

2. Vacuum any sediment from inside the boiler and

components. Remove any obstructions.

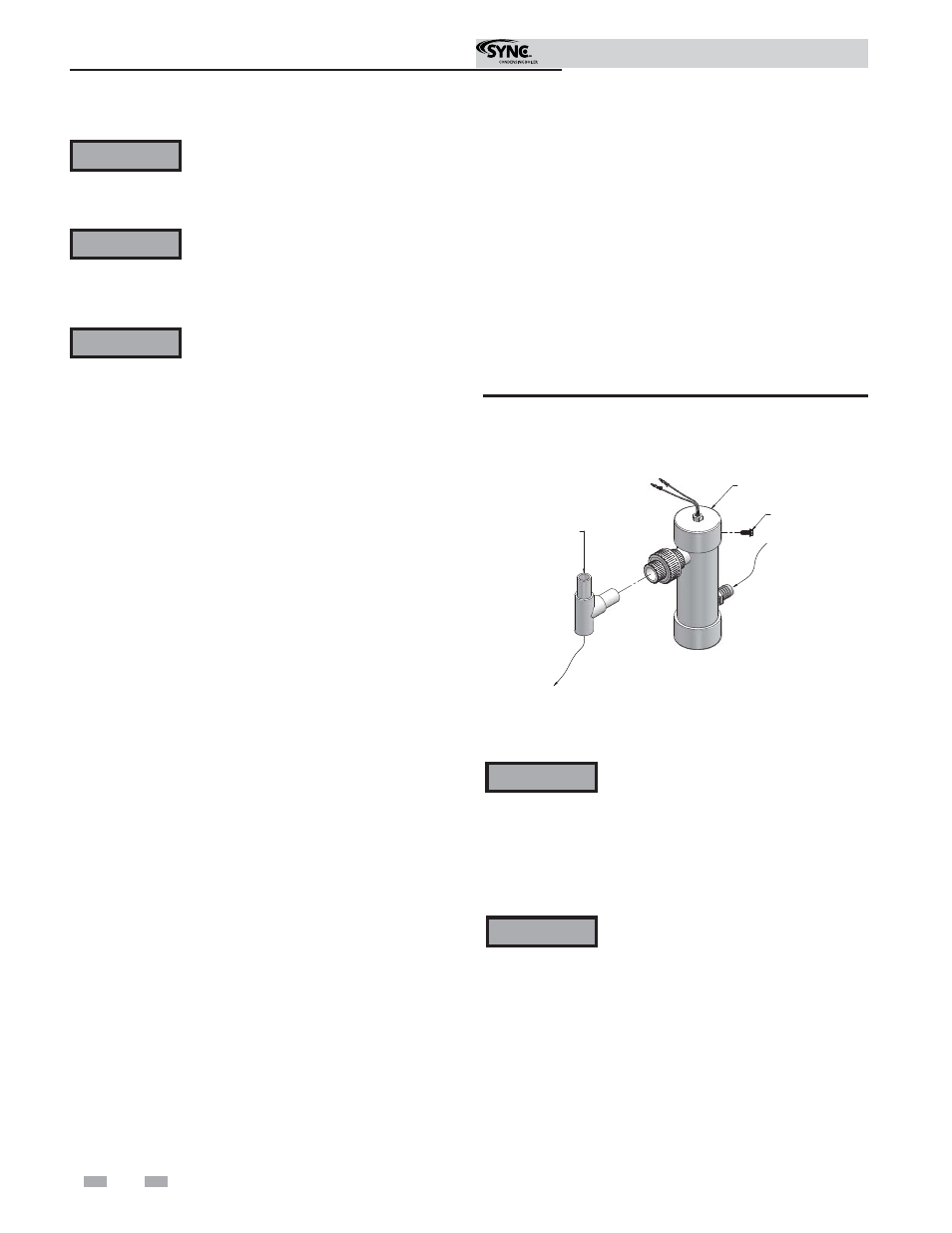

Clean condensate trap

1. Inspect the condensate drain line, condensate PVC

fittings, and condensate trap.

2. Remove the PVC cap retaining screw from the PVC cap

(FIG. 11-1).

3. Remove the 2 inch PVC cap with the switch located at the

top of the trap (FIG. 11-1).

4. Remove any sediment in the trap.

5. Fill with fresh water until the water begins to pour out of

the drain.

6. Replace the cap. Press the cap onto the trap until the cap

makes contact with the drain.

7. Replace the retaining screw.

Eliminate all system or boiler leaks.

Continual fresh makeup water will

reduce boiler life. Minerals can build

up in sections, reducing heat transfer,

overheating heat exchanger, and causing

heat exchanger failure. Leaking water may

also cause severe property damage.

1. Inspect all water and gas piping and verify to be leak free.

2. Look for signs of leaking lines and correct any problems

found.

3. Check gas line using the procedure found in Section 6

- Gas Connections.

Check all piping for leaks

The condensate trap must be filled with

water during all times of boiler operation

to avoid flue gas emission from the

condensate drain line. Failure to fill the

trap could result in severe personal injury

or death.

ƽ WARNING

ƽ WARNING

ƽ WARNING

ƽ WARNING

ƽ WARNING

CONDENSATE FROM

HEAT EXCHANGER

RETAINING

SCREW

2” PVC CAP WITH

BLOCKED DRAIN SWITCH

PVC TEE ASSEMBLY

(FACTORY SUPPLIED)

TO FLOOR

DRAIN

Figure 11-1 Condensate Trap