General, Venting – Lochinvar 1 User Manual

Page 18

18

Installation & Operation Manual

PVC/CPVC air intake/vent connections

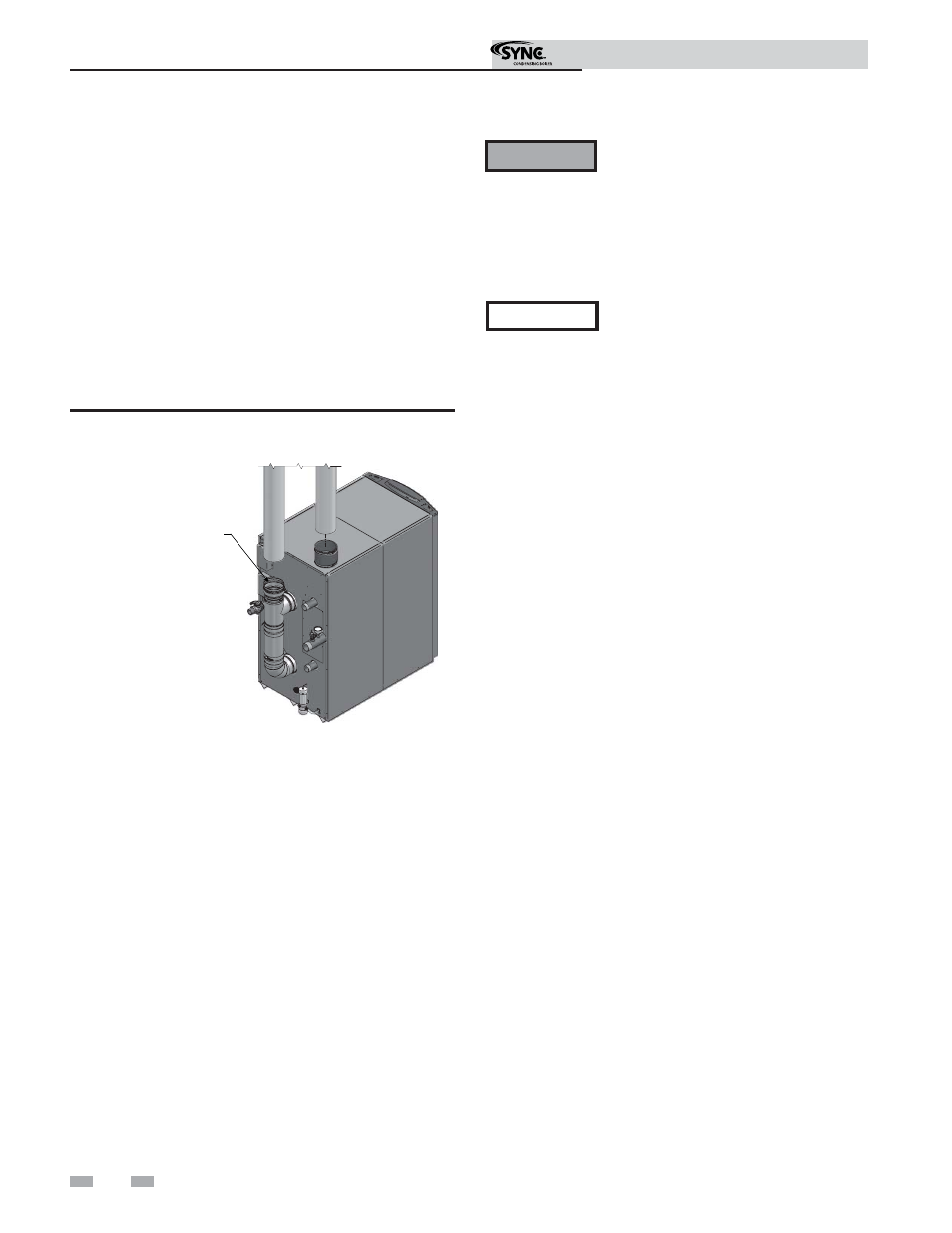

1. Combustion Air Intake Connector (FIG. 2-2) - Used to

provide combustion air directly to the unit from

outdoors. A fitting is provided on the unit for final

connection. Combustion air piping must be supported

per guidelines listed in the National Mechanical Code,

Section 305, Table 305.4 or as local codes dictate.

2. Vent Connector (FIG. 2-2) - Used to provide a

passageway for conveying combustion gases to the

outside. A transition fitting is provided on the unit for

final connection. Vent piping must be supported per the

National Building Code, Section 305, Table 305.4 or as

local codes dictate.

VENT

AIR

PVC/CPVC ADAPTER

FACTORY INSTALLED

Figure 2-2 Near Boiler PVC/CPVC Venting

Air inlet pipe materials:

The air inlet pipe(s) must be sealed. Choose acceptable

combustion air inlet pipe materials from the following list:

PVC, CPVC or ABS

Dryer Vent or Sealed Flexible Duct (not recommended

for rooftop air inlet)

Galvanized steel vent pipe with joints and seams sealed

as specified in this section.

Type “B” double-wall vent with joints and seams sealed

as specified in this section.

AL29-4C, stainless steel material to be sealed to

specification of its manufacturer.

*Plastic pipe may require an adapter (not provided) to

transition between the air inlet connection on the appliance

and the plastic air inlet pipe.

ƽ WARNING Using vent or air intake materials other

than those specified, failure to properly

seal all seams and joints or failure to follow

vent pipe manufacturer’s instructions can

result in personal injury, death or property

damage. Mixing of venting materials will

void the warranty and certification of the

appliance.

NOTICE

The use of double-wall vent or insulated

material for the combustion air inlet

pipe is recommended in cold climates

to prevent the condensation of airborne

moisture in the incoming combustion air.

Sealing of Type “B” double-wall vent material or galvanized

vent pipe material used for air inlet piping on a sidewall or

vertical rooftop Combustion Air Supply System:

a. Seal all joints and seams of the air inlet pipe using either

Aluminum Foil Duct Tape meeting UL Standard 723 or

181A-P or a high quality UL Listed silicone sealant such

as those manufactured by Dow Corning or General

Electric.

b. Do not install seams of vent pipe on the bottom of

horizontal

runs.

c. Secure all joints with a minimum of three sheet metal

screws or pop rivets. Apply Aluminum Foil Duct Tape or

silicone sealant to all screws or rivets installed in the vent

pipe.

d. Ensure that the air inlet pipes are properly supported.

The PVC, CPVC, or ABS air inlet pipe should be cleaned and

sealed with the pipe manufacturer’s recommended solvents

and standard commercial pipe cement for the material used.

The PVC, CPVC, ABS, Dryer Vent or Flex Duct air inlet pipe

should use a silicone sealant to ensure a proper seal at the

appliance connection and the air inlet cap connection. Dryer

vent or flex duct should use a screw type clamp to seal the

vent to the appliance air inlet and the air inlet cap. Proper

sealing of the air inlet pipe ensures that combustion air will be

free of contaminants and supplied in proper volume.

2

General

venting