General, Venting – Lochinvar Knight Wall Mount Soiler 51-211 User Manual

Page 19

19

3

General

venting

(continued)

Installation & Operation Manual

Installing vent and air piping

Use only cleaners, primers, and solvents

that are approved for the materials which

are joined together.

NOTICE

1. Work from the boiler to vent or air termination. Do not

exceed the lengths given in this manual for the air or vent

piping.

2. Cut pipe to the required lengths and deburr the inside

and outside of the pipe ends.

3. Chamfer outside of each pipe end to ensure even

cement distribution when joining.

4. Clean all pipe ends and fittings using a clean dry rag.

(Moisture will retard curing and dirt or grease will prevent

adhesion.)

5. Dry fit vent or air piping to ensure proper fit up before

assembling any joint. The pipe should go a third to

two-thirds into the fitting to ensure proper sealing after

cement is applied.

6. Priming

and

Cementing:

a. Handle fittings and pipes carefully to prevent

contamination

of

surfaces.

b. Apply a liberal even coat of primer to the fitting

socket and to the pipe end to approximately 1/2"

beyond the socket depth.

c. Apply a second primer coat to the fitting socket.

d. While primer is still wet, apply an even coat of

approved cement to the pipe equal to the depth of

the fitting socket along with an even coat of

approved cement to the fitting socket.

e. Apply a second coat of cement to the pipe.

f.

While the cement is still wet, insert the pipe into

the fitting, if possible twist the pipe a 1/4 turn as

you insert it. NOTE: If voids are present,

sufficient cement was not applied and joint could

be

defective.

g.

Wipe excess cement from the joint removing ring or

beads as it will needlessly soften the pipe.

PVC/CPVC

Table 3D PVC/CPVC Vent Pipe, and Fittings

All PVC vent pipes must be glued, properly

supported, and the exhaust must be

pitched a minimum of a 1/4 inch per foot

back to the boiler (to allow drainage of

condensate).

NOTICE

ƽ WARNING The vent connection to the appliance must

be made with the starter piece provided

with the appliance if PVC/CPVC vent is to

be used. The field provided vent fittings

must be cemented to the CPVC pipe section

using an “All Purpose Cement” suitable for

PVC and CPVC pipe. Use only the vent

materials, primer, and cement specified in

Table 3D to make the vent connections.

Failure to follow this warning could result

in fire, personal injury, or death.

ƽ WARNING

Insulation should not be used on PVC

or CPVC venting materials. The use of

insulation will cause increased vent wall

temperatures, which could result in vent

pipe failure.

Approved PVC/CPVC Vent Pipe and Fittings

Item

Material

Standard

Vent pipe

PVC Schedule 40, 80 ANSI/ASTM D1785

PVC - DWV

ANSI/ASTM D2665

CPVC Schedule 40, 80 ANSI/ASTM F441

Vent fittings

PVC Schedule 40

ANSI/ASTM D2466

PVC Schedule 80

ANSI/ASTM D2467

CPVC Schedule 80

ANSI/ASTM F439

Pipe Cement /

Primer

PVC

ANSI/ASTM D2564

CPVC

ANSI/ASTM F493

NOTICE: DO NOT USE CELLULAR (FOAM) CORE PIPE

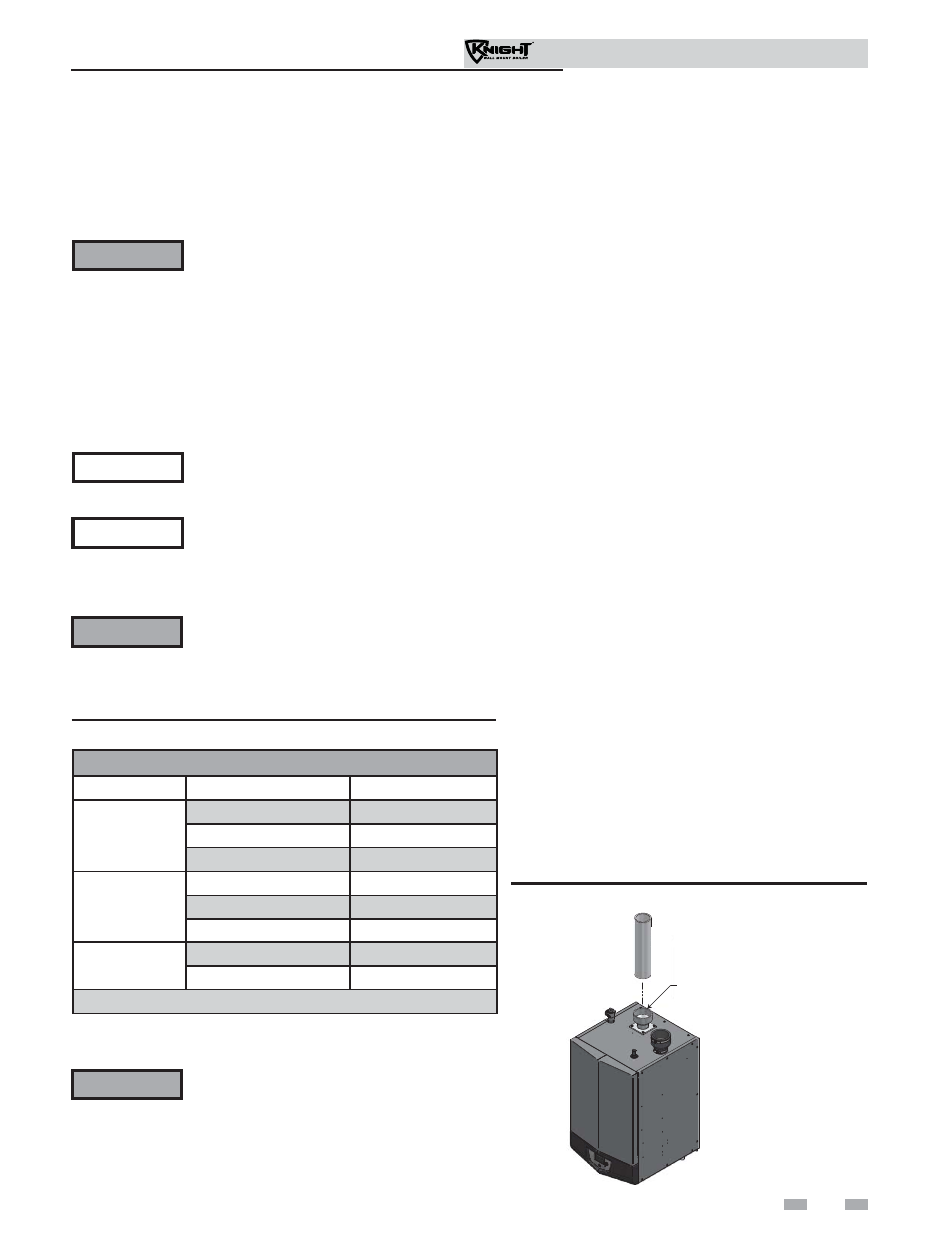

Figure 3-7 Near Boiler PVC/CPVC Venting

This product has been approved for use with the PVC/CPVC

vent materials listed in Table 3D.

NOTE: In Canada, CPVC and PVC vent pipe, fi ttings and cement/

primer must be ULC-S636 certifi ed.

CPVC STARTER PIECE

For models 51 - 106 when transitioning from 2

to 3 inch vent diameter, a 2" pipe section and

2"to 3" increaser are required to be CPVC when

PVC/CPVC vent is used.

For installations using 2" vent, the first seven

(7) equivalent feet of vent must be CPVC (field

supplied). See examples on this page.

ƽ WARNING

Examples: 1. Seven (7) feet vertical

2. Connector + 90° elbow + 2 feet horizontal

3. One (1) foot vertical + 90° elbow + 1 foot

horizontal