Theory of operation, General description, General functional description – Lincoln Electric POWER FEED SVM185-A User Manual

Page 70

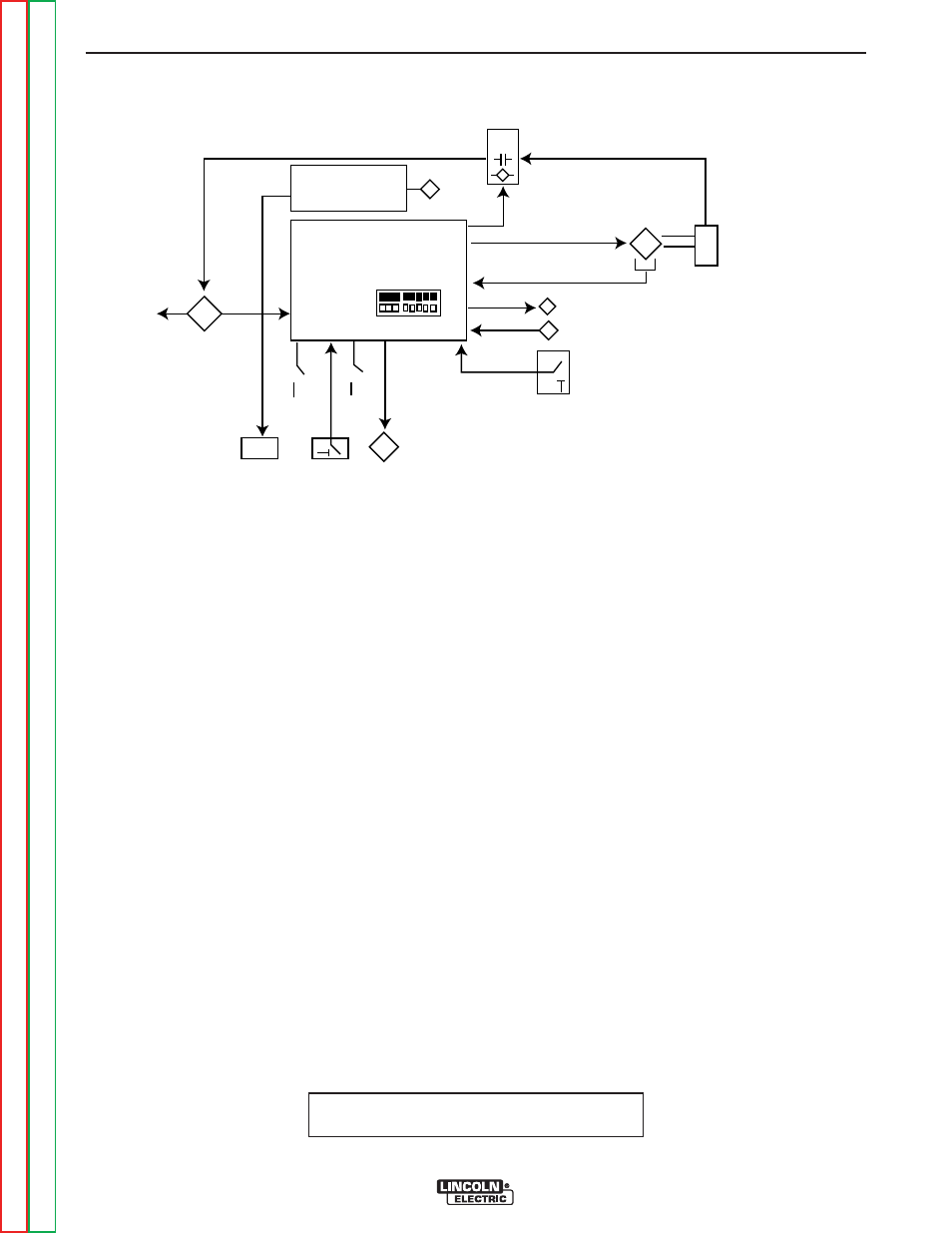

VOLTAGE

SENSE

LEAD #67A

LEAD #67

PUSH PULL

DAUGHTER

DRIVE

MOTOR

GEAR BOX

AND

CONDUCTOR

BLOCK

FEEDBACK

TACH

STATUS LED

GUN TIGGER AND

DUAL PROCEDURE

RECEPTACLE

2-STEP/

4-STEP

CONTROL BOARD

FEEDHEAD

DIP SWITCHES

TO POWER

SOURCE

INPUT

NETWORK

RECEPTACLE

HEATER LIGHT

CONNECTOR

FOOT AMPTROL

COLD

INCH/

GAS

PURGE

GAS

SOLENOID

THEORY OF OPERATION

E-2

E-2

POWER FEED® 25M

GENERAL DESCRIPTION

The POWER FEED® 25 Single Wire Feeder is a wire

feeder, consisting of two components - a

wire drive

and a

control box

- are available assembled as a

bench unit

or as a

boom system

. High speed, highly

reliable digital cables connect the components togeth-

er and to the Power Wave power source.

The POWER FEED® 25M Wire Feeder system has the

ability to connect to one power source, use the same

power source.

The powerful two roll wire drive system sets the indus-

try standard for ease of use. Its patented design allows

for tool-less change out of wire guides and drive rolls

greatly reducing set up time.

FIGURE E.2 - GENERAL PHYSICAL DESCRIPTION

GENERAL FUNCTIONAL

DESCRIPTION

• The POWER FEED® 25M Wire Feeder is a highly

versatile wire feeder with easy to use features that

make it easy for the operator to adjust the arc for

specific preferences.

• The new MSP4 panel clearly displays key welding

information. Use the MSP4 panel to quickly adjust

weld settings, arc starting parameters, arc end para-

meters and set-up variables.

• The POWER FEED® 25M Wire Feeder is provided

with an infrared red (IR) port. Transferring welding

settings is accomplished with a common palm com-

puter.

• When the POWER FEED® 25M Wire Feeder is cou-

pled to a Power Wave welding power source, the

result is a welding system with absolutely superior

arc performance.

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion