Lincoln Electric Welder User Manual

Page 8

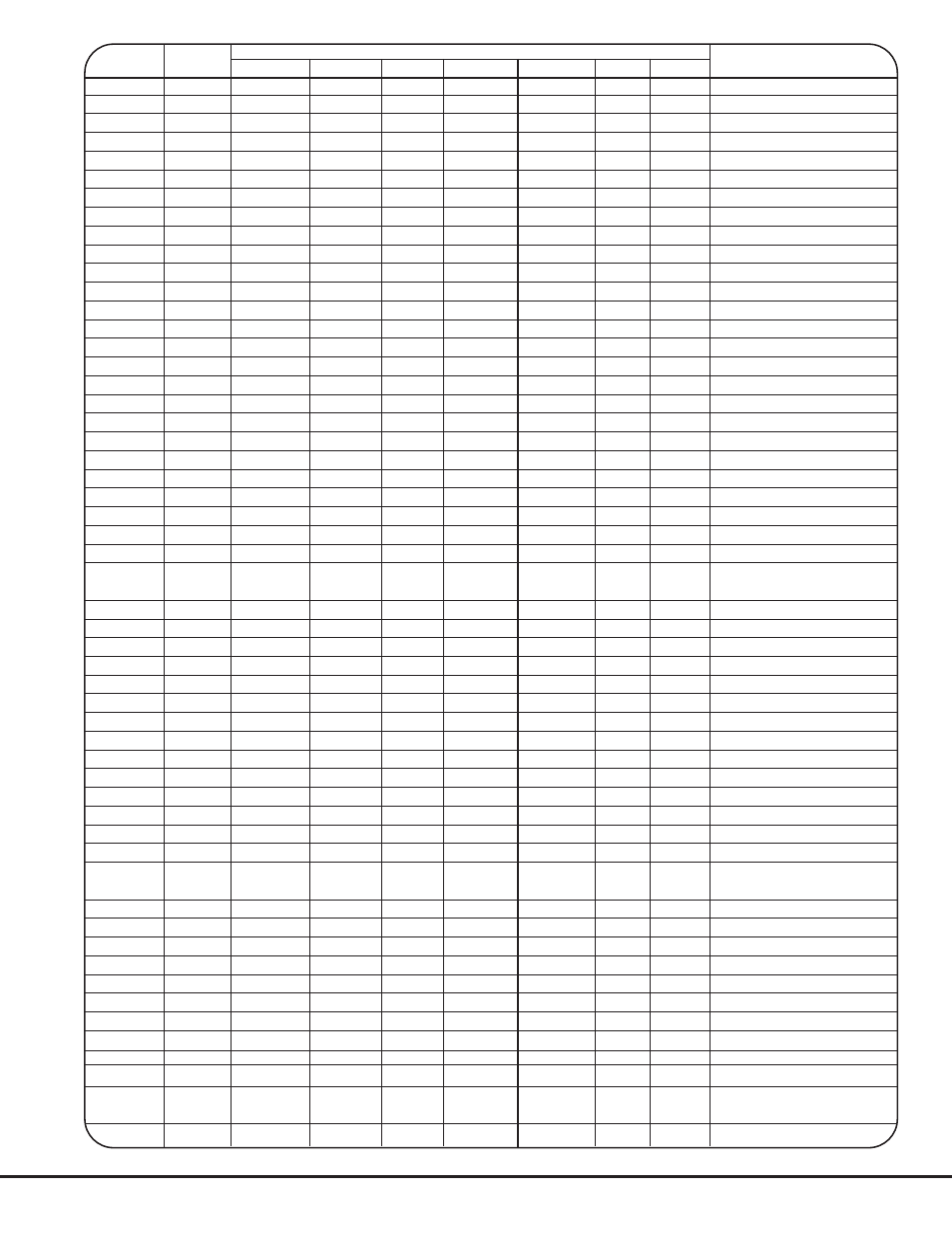

*Single values are maximum values.

(From ASM Metals Handbook, Ninth Edition, Volume 3)

UNS

Composition - Percent *

Type

Number

C

Mn

Si

Cr

Ni

P

S

Other

201

S20100

0.15

5.5-7.5

1.00

16.0-18.0

3.5-5.5

0.06

0.03

0.25 N

202

S20200

0.15

7.5-10.0

1.00

17.0-19.0

4.0-6.0

0.06

0.03

0.25 N

205

S20500

0.12-0.25

14.0-15.5

1.00

16.5-18.0

1.0-1.75

0.06

0.03

0.32-0.40 N

216

S21600

0.08

7.5-9.0

1.00

17.5-22.0

5.0-7.0

0.045

0.03

2.0-3.0 Mo; 0.25-0.5 N

301

S30100

0.15

2.00

1.00

16.0-18.0

6.0-8.0

0.045

0.03

302

S30200

0.15

2.00

1.00

17.0-19.0

8.0-10.0

0.045

0.03

302B

S30215

0.15

2.00

2.0-3.0

17.0-19.0

8.0-10.0

0.045

0.03

303**

S30300

0.15

2.00

1.00

17.0-19.0

8.0-10.0

0.20

0.15 min.

0.6 Mo

303Se**

S30323

0.15

2.00

1.00

17.0-19.0

8.0-10.0

0.20

0.06

0.15 min. Se

304

S30400

0.08

2.00

1.00

18.0-20.0

8.0-10.5

0.045

0.03

304H

S30409

0.04-0.10

2.00

1.00

18.0-20.0

8.0-10.5

0.045

0.03

304L

S30403

0.03

2.00

1.00

18.0-20.0

8.0-12.0

0.045

0.03

304LN

S30453

0.03

2.00

1.00

18.0-20.0

8.0-10.5

0.045

0.03

0.10-0.15 N

S30430

S30430

0.08

2.00

1.00

17.0-19.0

8.0-10.0

0.045

0.03

3.0-4.0 Cu

304N

S30451

0.08

2.00

1.00

18.0-20.0

8.0-10.5

0.045

0.03

0.10-0.16 N

304HN

S30452

0.04-0.10

2.00

1.00

18.0-20.0

8.0-10.5

0.045

0.03

0.10-0.16 N

305

S30500

0.12

2.00

1.00

17.0-19.0

10.5-13.0

0.045

0.03

308

S30800

0.08

2.00

1.00

19.0-21.0

10.0-12.0

0.045

0.03

308L

0.03

2.00

1.00

19.0-21.0

10.0-12.0

0.045

0.03

309

S30900

0.20

2.00

1.00

22.0-24.0

12.0-15.0

0.045

0.03

309S

S30908

0.08

2.00

1.00

22.0-24.0

12.0-15.0

0.045

0.03

309S Cb

S30940

0.08

2.00

1.00

22.0-24.0

12.0-15.0

0.045

0.03

8 x %C - Nb(Cb)

309 Cb + Ta

0.08

2.00

1.00

22.0-24.0

12.0-15.0

0.045

0.03

8 x %C (Nb(Cb) + Ta)

310

S31000

0.25

2.00

1.50

24.0-26.0

19.0-22.0

0.045

0.03

310S

S31008

0.08

2.00

1.50

24.0-26.0

19.0-22.0

0.045

0.03

312

0.15

2.00

1.00

30.0 nom.

9.0 nom.

0.045

0.03

254SMo

S31254

0.020

1.00

0.80

19.5-20.5

17.50-18.5

0.03

0.010

6.00-6.50Mo; 0.18-0.22N;

Cu=0.5-1.00

314

S31400

0.25

2.00

1.5-3.0

23.0-26.0

19.0-22.0

0.045

0.03

316

S31600

0.08

2.00

1.00

16.0-18.0

10.0-14.0

0.045

0.03

2.0-3.0 Mo

316F**

S31620

0.08

2.00

1.00

16.0-18.0

10.0-14.0

0.20

0.10 min.

1.75-2.5 Mo

316H

S31609

0.04-0.10

2.00

1.00

16.0-18.0

10.0-14.0

0.045

0.03

2.0-3.0 Mo

316L

S31603

0.03

2.00

1.00

16.0-18.0

10.0-14.0

0.045

0.03

2.0-3.0 Mo

316LN

S31653

0.03

2.00

1.00

16.0-18.0

10.0-14.0

0.045

0.03

2.0-3.0 Mo; 0.10-0.30 N

316N

S31651

0.08

2.00

1.00

16.0-18.0

10.0-14.0

0.045

0.03

2.0-3.0 Mo; 0.10-0.16 N

317

S31700

0.08

2.00

1.00

18.0-20.0

11.0-15.0

0.045

0.03

3.0-4.0 Mo

317L

S31703

0.03

2.00

1.00

18.0-20.0

11.0-15.0

0.045

0.03

3.0-4.0 Mo

317M

S31725

0.03

2.00

1.00

18.0-20.0

12.0-16.0

0.045

0.03

4.0-5.0 Mo

321

S32100

0.08

2.00

1.00

17.0-19.0

9.0-12.0

0.045

0.03

5 x %C min. Ti

321H

S32109

0.04-0.10

2.00

1.00

17.0-19.0

9.0-12.0

0.045

0.03

5 x %C min. Ti

329

S32900

0.10

2.00

1.00

25.0-30.0

3.0-6.0

0.045

0.03

1.0-2.0 Mo

330

N08330

0.08

2.00

0.75-1.5

17.0-20.0

34.0-37.0

0.04

0.03

AL6-XN

N80367

0.030

2.00

1.00

20.0-22.0

23.5-25.5

0.04

0.03

6.00-7.00Mo; 0.18-0.25N;

Cu=0.75

330HC

0.40

1.50

1.25

19.0 nom.

35.0 nom.

332

0.04

1.00

0.50

21.5 nom.

32.0 nom.

0.045

0.03

347

S34700

0.08

2.00

1.00

17.0-19.0

9.0-13.0

0.045

0.03

10 x %C min. Nb(Cb) +Ta

347H

S34709

0.04-0.10

2.00

1.00

17.0-19.0

9.0-13.0

0.045

0.03

10 x %C min. Nb(Cb) + Ta

348

S34800

0.08

2.00

1.00

17.0-19.0

9.0-13.0

0.045

0.03

0.2 Cu; 10 x %C min. Nb(Cb) + Ta(c)

348H

S34809

0.04-0.10

2.00

1.00

17.0-19.0

9.0-13.0

0.045

0.03

0.2 Cu; 10 x %C min. Nb(Cb) + Ta

384

S38400

0.08

2.00

1.00

15.0-17.0

17.0-19.0

0.045

0.03

Nitronic 32

S24100

0.10

12.0

0.50

18.0

1.6

0.35 N

Nitronic 33

S24000

0.06

13.0

0.5

18.0

3.0

0.30 N

Nitronic 40

S21900

0.08

8.0-10.0

1.00

18.0-20.0

5.0-7.0

0.06

0.03

0.15-0.40 N

Nitronic 50

S20910

0.06

4.0-6.0

1.00

20.5-23.5

11.5-13.5

0.04

0.03

1.5-3.0 Mo; 0.2-0.4 N;

0.1-0.3 Cb; 0.1-0.3 V

Nitronic 60

S21800

0.10

7.0-9.0

3.5-4.5

16.0-18.0

8.0-9.0

0.04

0.03

1.5-3.0 Mo; 0.2-0.4 N;

TABLE III — Nominal Compositions of Austenitic Stainless Steels

**These grades are generally

considered to be unweldable.

6