Lincoln Electric Welder User Manual

Page 26

24

multipass welds.

Submerged arc welding creates a

large volume of molten metal that

remains fluid for appreciable time. It

is essential that this molten metal be

supported and contained until it has

solidified. The two most common

means of weld backing are

nonfusible backing and fusible

backing.

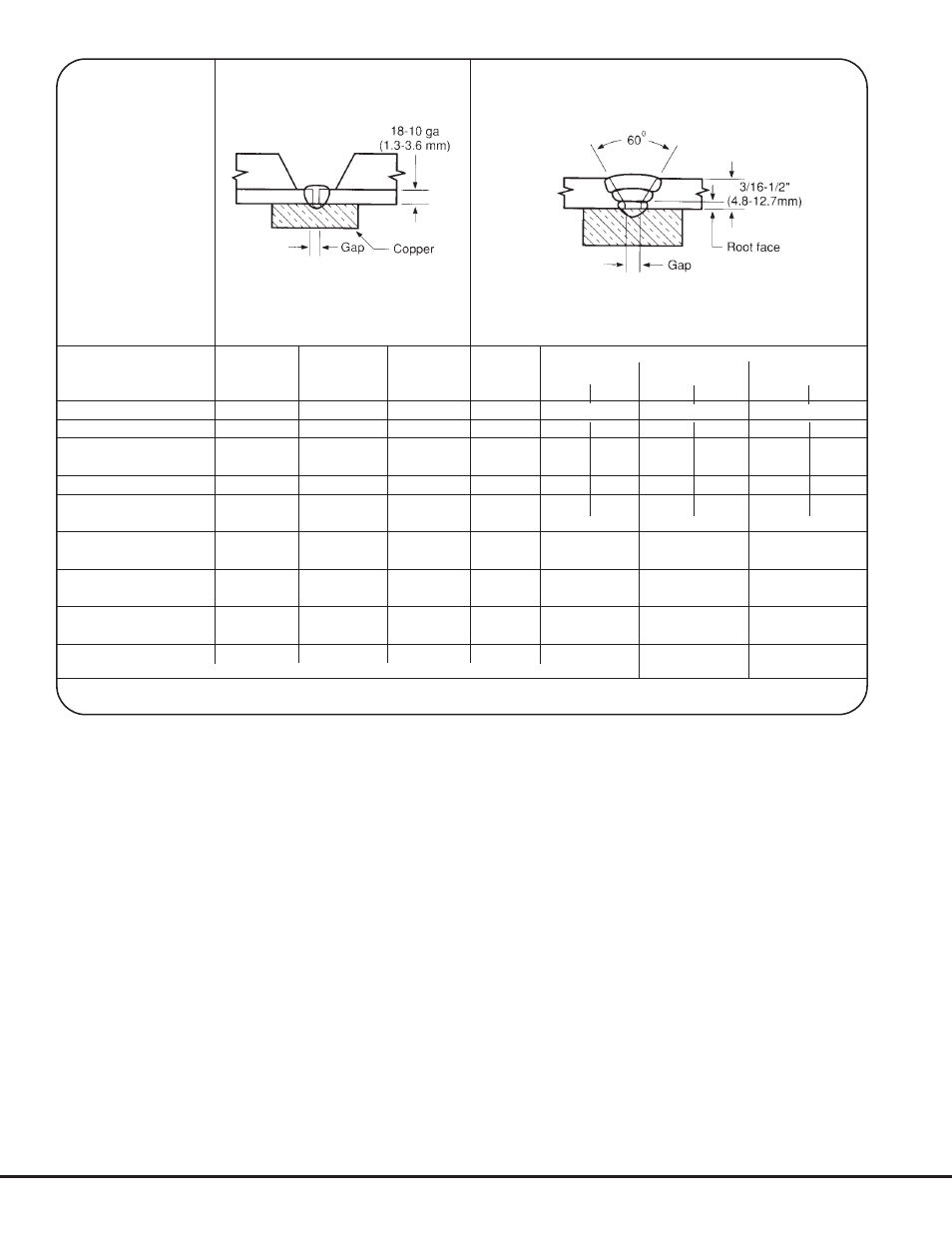

Copper backing is the most

frequently used nonfusible backing in

the welding of stainless steel. When

copper is used as a chill bar, care

must be taken to prevent copper

grain boundary penetration. Recom -

mended groove dimensions are

shown in Figure 13. Ceramic

backing tapes are also sometimes

used.

With a fusible metallic backing, the

weld penetrates into and fuses with

the stainless backing, which either

temporarily or permanently becomes

an integral part of the assembly.

Most submerged arc welding is done

in the flat position. This results in the

best bead contour and ease of

operation. Occasionally, welding is

done on circumferential seams.

Figure 14 illustrates the effect of

various inclinations.

Submerged arc fluxes are available

as proprietary materials for welding

stainless steel. Composition of

materials fall into two categories –

fused type and bonded type. The

fused type is glasslike and is

produced by melting the ingredients

at high temperatures followed by

crushing to granulate the flux. The

bonded or agglomerated type is

produced by mixing the ingredients

with a suitable binder and baking

the mixture. Lincoln manufactures

only bonded fluxes.

Alloying elements can be added to

the weld deposit through some

bonded fluxes. These include

chromium, nickel, molybdenum and

niobium (columbium). If alloying

Welding Position: Flat

Weld Quality Level: Code

Steel Weldability: Good

Plate Thickness in.

0.050 (18 ga)

0.078 (14 ga)

0.140 (10 ga)

3/16

1/4

3/8

1/2

Plate Thickness

mm.

1.3

2.0

3.6

4.8

6.4

9.5

12.7

Pass

1

1

1

1

1

2

1

2-3

1

2-5

Electrode Class

E3XX-16

E3XX-16

E3XX-16

E3XX-16

E3XX-16

E3XX-16

E3XX-16

Electrode

Size in.

5/64

3/32

1/8

5/32

5/32

3/16

5/32

3/16

5/32

3/16

Electrode Size

mm.

2.0

2.4

3.2

4.0

4.0

4.8

4.0

4.8

4.0

4.8

Current (amp) DC (+)

40*

60

85

125

125

160

125

160

125

160

Arc Speed (in./min.)

14 -16

11.5 - 12.5

8.5 - 9.5

6.7 - 7.3

5.7-6.3 7.6-8.4

5.7-6.3

5.7-6.3

5.7-6.3

5.7-6.3

Arc Speed

mm/sec

5.9 - 6.8

4.9 - 5.3

3.6 -4.0

2.8 - 3.1

2.4-2.7 3.2-3.6

2.4-2.7

2.4-2.7

2.4-2.7

2.4-2.7

Electrode Req’d (lb./ft.)

0.020

0.038

0.080

0.150

0.340

0.650

1.06

Electrode Req’d

kg/m

0.030

0.057

0.119

0.223

0.506

0.968

1.579

Total Time (hr./ft. of weld)

0.0133

0.0167

0.0222

0.0286

0.0583

0.100

0.167

Total Time

hrs./m of weld

0.0436

0.0548

0.0728

0.0938

0.1913

0.3281

0.5479

Gap (in.)

0

1/32

1/32

1/16

3/32

3/32

3/32

Gap

mm

0

0.8

0.8

1.6

2.4

2.4

2.4

Root Face (in.)

0

0

0

1/16

1/16

1/16

1/16

Root Face

mm

0

0

0

1.6

1.6

1.6

1.6

*Use DC (–)

Note: AC can be used with 10% increase in current. E3XX-15 electrode can be used with a 10% decrease in current.

FIGURE 6 — Suggested procedures for SMAW of butt joints in austenitic stainless steel from 18 (1.3 mm) gauge

to 1/2 inch (12.7 mm) thickness in the flat position.