2 martensitic stainless steels – Lincoln Electric Welder User Manual

Page 5

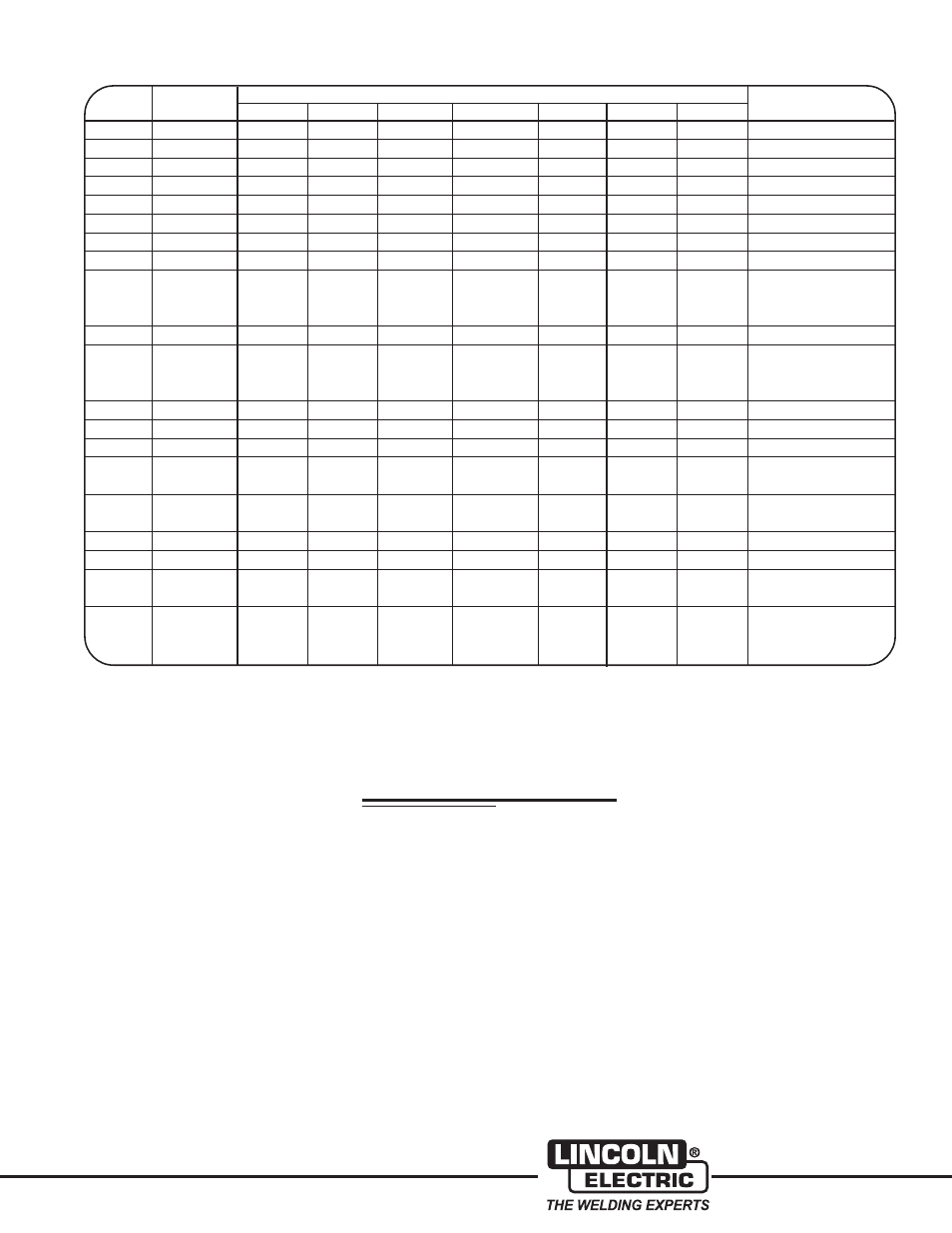

UNS

Composition - Percent *

Type

Number

C

Mn

Si

Cr

Ni

P

S

Other

405

S40500

0.08

1.00

1.00

11.5-14.5

0.04

0.03

0.10-0.30 Al

409

S40900

0.08

1.00

1.00

10.5-11.75

0.045

0.045

6 x %C min. TI

429

S42900

0.12

1.00

1.00

14.0-16.0

0.04

0.03

430

S43000

0.12

1.00

1.00

16.0-18.0

0.04

0.03

430F**

S43020

0.12

1.25

1.00

16.0-18.0

0.06

0.15 min.

0.06 Mo

430FSe**

S43023

0.12

1.25

1.00

16.0-18.0

0.06

0.06

0.15 min. Se

430Ti

S43036

0.10

1.00

1.00

16.0-19.5

0.75

0.04

0.03

5 x %C - Ti min.

434

S43400

0.12

1.00

1.00

16.0-18.0

0.04

0.03

0.75-1.25 Mo

436

S43600

0.12

1.00

1.00

16.0-18.0

0.04

0.03

0.75-1.25 Mo;

5 x %C min.

Nb(Cb) + Ta

442

S44200

0.20

1.00

1.00

18.0-23.0

0.04

0.03

444

S44400

0.025

1.00

1.00

17.5-19.5

1.00

0.04

0.03

1.75-2.5 Mo, 0.035 N

0.2 + 4 (%C + %N);

(Ti +Nb(Cb) )

446

S44600

0.20

1.50

1.00

23.0-27.0

0.04

0.03

0.25 N

18-2FM**

S18200

0.08

2.50

1.00

17.5-19.5

0.04

0.15 min.

18SR

0.04

0.3

1.00

18.0

2.0 Al; 0.4 Ti

26-1

S44625

0.01

0.40

0.40

25.0-27.5

0.50

0.02

0.02

0.75-1.5 Mo; 0.015N;

(E-Brite)

0.2 Cu; 0.5 (Ni+Cu)

26-1Ti

S44626

0.06

0.75

0.75

25.0-27.0

0.5

0.04

0.02

0.75-1.5 Mo; 0.04 N;

0.2 Cu; 0.2-1.0 Ti

29-4

S44700

0.01

0.30

0.20

28.0-30.0

0.15

0.025

0.02

3.5-4.2 Mo

29-4-2

S44800

0.01

0.30

0.20

28.0-30.0

2.0-2.5

0.025

0.02

3.5-4.2 Mo

Monit

S44635

0.25

1.00

0.75

24.5-26.0

3.5-4.5

0.04

0.03

3.5-4.5 Mo;

0.3-0.6 (Ti + Nb(Cb) )

Sea-cure/

S44660

0.025

1.00

0.75

25.0-27.0

1.5-3.5

0.04

0.03

2.5-3.5 Mo;

Sc-1

0.2 + 4 (%C + %N)

(Ti + Nb(Cb) )

of a number of standard and several

non-standard ferritic stainless steels.

They are characterized by weld and

HAZ grain growth which can result in

low toughness of welds.

To weld the ferritic stainless steels,

filler metals should be used which

match or exceed the Cr level of the

base alloy. Type 409 is available as

metal cored wire and Type 430 is

available in all forms. Austenitic

Types 309 and 312 may be used for

dissimilar joints. To minimize grain

growth, weld heat input should be

minimized, Preheat should be limited

to 300-450°F and used only for the

higher carbon ferritic stainless steels

(e.g., 430, 434, 442 and 446). Many

of the highly alloyed ferritic stainless

steels are only available in sheet and

tube forms and are usually welded

by GTA without filler metal.

3.2

MARTENSITIC

STAINLESS STEELS

The martensitic stainless steels

contain 11 to 18% Cr, up to 1.20% C

and small amounts of Mn and Ni

and, sometimes, Mo. These steels

will transform to austenite on heating

and, therefore, can be hardened by

formation of martensite on cooling.

This group includes Types 403, 410,

414, 416, 420, 422, 431 and 440.

Both standard and non-standard

martensitic stainless steels are listed

in Table II. They have a tendency

toward weld cracking on cooling

when hard brittle martensite is

formed.

Chromium and carbon content of the

filler metal should generally match

these elements in the base metal.

Type 410 filler is available as covered

electrode, solid wire and cored wire

and can be used to weld types 402,

410, 414 and 420 steels. Type

410NiMo filler metal can also be

used. When it is necessary to match

the carbon in Type 420 steel, Type

420 filler, which is available as solid

wire and cored wire, should be used.

Types 308, 309 and 310 austenitic

filler metals can be used to weld the

martensitic steels to themselves or to

other steels where good as-

deposited toughness is required.

Preheating and interpass temperature

in the 400 to 600°F (204 to 316°C)

range is recommended for most

3

*Single values are maximum values.

(From ASM Metals Handbook, Ninth Edition, Volume 3)

TABLE I — Nominal Compositions of Ferritic Stainless Steels

**These grades are generally

considered to be unweldable.