0 selection of a welding process – Lincoln Electric Welder User Manual

Page 20

18

sheets are plug welded at frequent

intervals to join them closely to the

shell.

2. Overlapping welds deposited on

the steel surface.

3. Small strips are overlapped or

placed side-by-side and welded to

the shell. Sometimes this technique is

referred to as “wallpapering”

Welding Clad Steel

Clad steel consists of stainless steel

sheet permanently bonded to mild

steel plate. To join clad steel plates,

first weld the mild steel with mild

steel electrodes. Do not tie into the

stainless cladding with the mild steel

electrodes. After gouging the back-

side of the first mild steel bead, weld

from the stainless side using

stainless steel electrodes.

Joining Manganese Steel

E308-X or E309-XX electrodes are

used to weld manganese steel to

carbon steel or to manganese steel.

The stainless welds provide excellent

joint strength and ductility but are

difficult to flame cut. Therefore, when

a manganese steel piece must be

replaced periodically, such as dipper

teeth, Wearshield Mangjet

®

electrode

can be recommended. Wearshield

15CrMn electrode has better crack

resistance, but the deposit is difficult

to flame cut.

Thick Harfacing Deposits

E308-X or E309-XX deposits

increase the toughness of thick

hardfacing deposits. For best results,

use one layer of stainless between

each two layers of hardfacing.

9.0

SELECTION OF

A WELDING

PROCESS

Joint Cleanliness

For high-quality welds, stainless steel

joints must be clean. The choice of

power brushing, degreasing, pickling,

grinding or simply wiping depends

upon the application and amount of

dirt. Here are some specific hints:

1. Remove all moisture by blowing

with dry air or heating with a torch.

Beware of moisture in air lines, damp

rags and humidity deposited

overnight.

2. Eliminate organic contaminants like

oil, paints, anti-spatter compounds,

grease, pencil marks, cutting

compounds, adhesive from

Bare

Dissimilar

Covered

Welding

PH Stainless

Designation

UNS No.

Electrodes

Wire

Steels

Martensitic Types

17-4PH

S17400

AMS 5827B, E630

AMS 5826

E or ER309,

and

(17-4 PH) or

(17-4 PH) or

E or ER309 Cb

15-5 PH

S15500

E308

ER308

Stainless W

S17600

E308 or

AMS 5805C

E or ERNiMo-3,

ENiMo-3

a

(A-286) or

E or ER309

ERNiMo-3

b

Semiaustenitic Types

17-7PH

S17700

AMS 5827B

AMS 5824A

E or ER310,

(17-4 PH),

(17-7 PH)

ENiCrFe-2, or

E308, or E309

ERNiCr-3

PH 15-7Mo

S15700

E308 or E309

AMS 5812C (PH 15-7Mo)

E or ER309, E or ER310

AM350

S35000

AMS 5775A (AM350)

AMS 5774B (AM350)

E or ER308, E or ER309

AM355

S35500

AMS 5781A (AM355)

AMS 5780A (AM355)

E or ER308, E or ER309

Austenitic Types

A-286

K66286

E309 or E310

ERNiCrFe-6 or

E or ER309,

ERNiMo-3

E or ER310

a. See AWS A5.11-97, Specification for Nickel and Nickel Alloy Welding Electrodes for Shielded Metal Arc Welding

b. See AWS A5.14-97, Specification for NIckel and Nickel Alloy Bare Welding Electrodes and Rod.

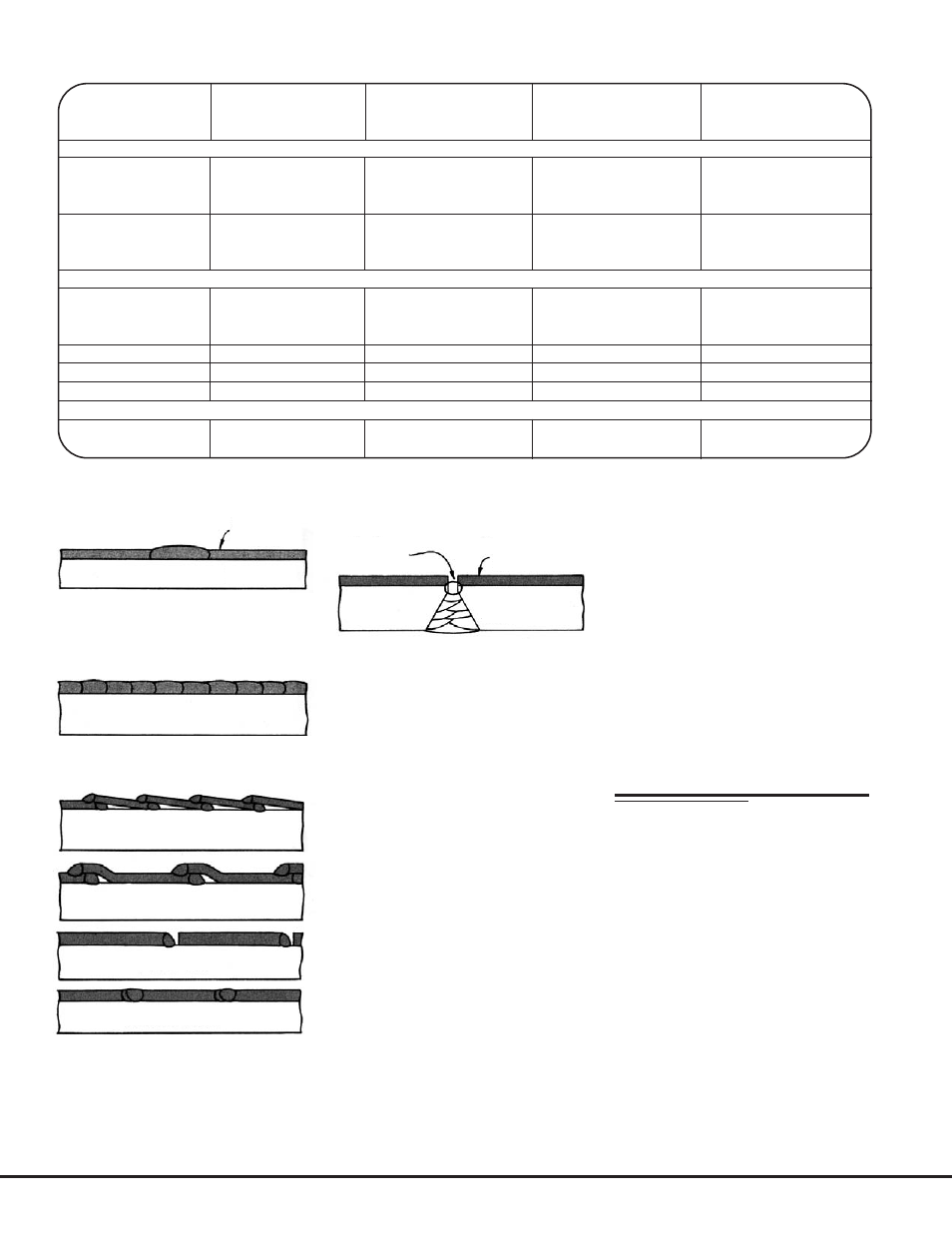

TABLE XIV — Filler Metals for Welding Precipitation-Hardening Stainless Steels

First Pass

Second Pass

Back

Gouge

Stainless

Steel

Stringer Beads

Mild Steel

Stainless

Steel

Mild Steel

Plug Weld