Lincoln Electric Welder User Manual

Page 33

31

Plate Thickness (in.)

1/16

3/32

1/8

3/16

1/4

1/2

mm.

1.6

2.4

3.2

4.8

6.4

12.7

Current DC(–)

80 - 100

100 - 120

120 - 140

200 - 250

200 - 350

225 - 375

Electrode Diameter (in.)

1/16

1/16

1/16

3/32

1/8

1/8

mm.

1.6

1.6

1.6

2.4

3.2

3.2

Gas Flow, Argon (cfh)

10

10

10

15

20

25

L/min..

4.7

4.7

4.7

7.1

9.4

11.8

Filler-Rod Diameter (in.)

1/16

1/16

3/32

1/8

1/8

1/8

mm.

1.6

1.6

2.4

3.2

3.2

3.2

Arc Speed (ipm)

12

12

12

10

8

8

mm/sec

5.1

5.1

5.1

4.2

3.4

3.4

Total Time (hr/ft of weld)

0.0167

0.0167

0.0167

0.0200

0.0250

0.0250

hr/m. of weld

0.0548

0.0548

0.0548

0.0656

0.0820

0.0820

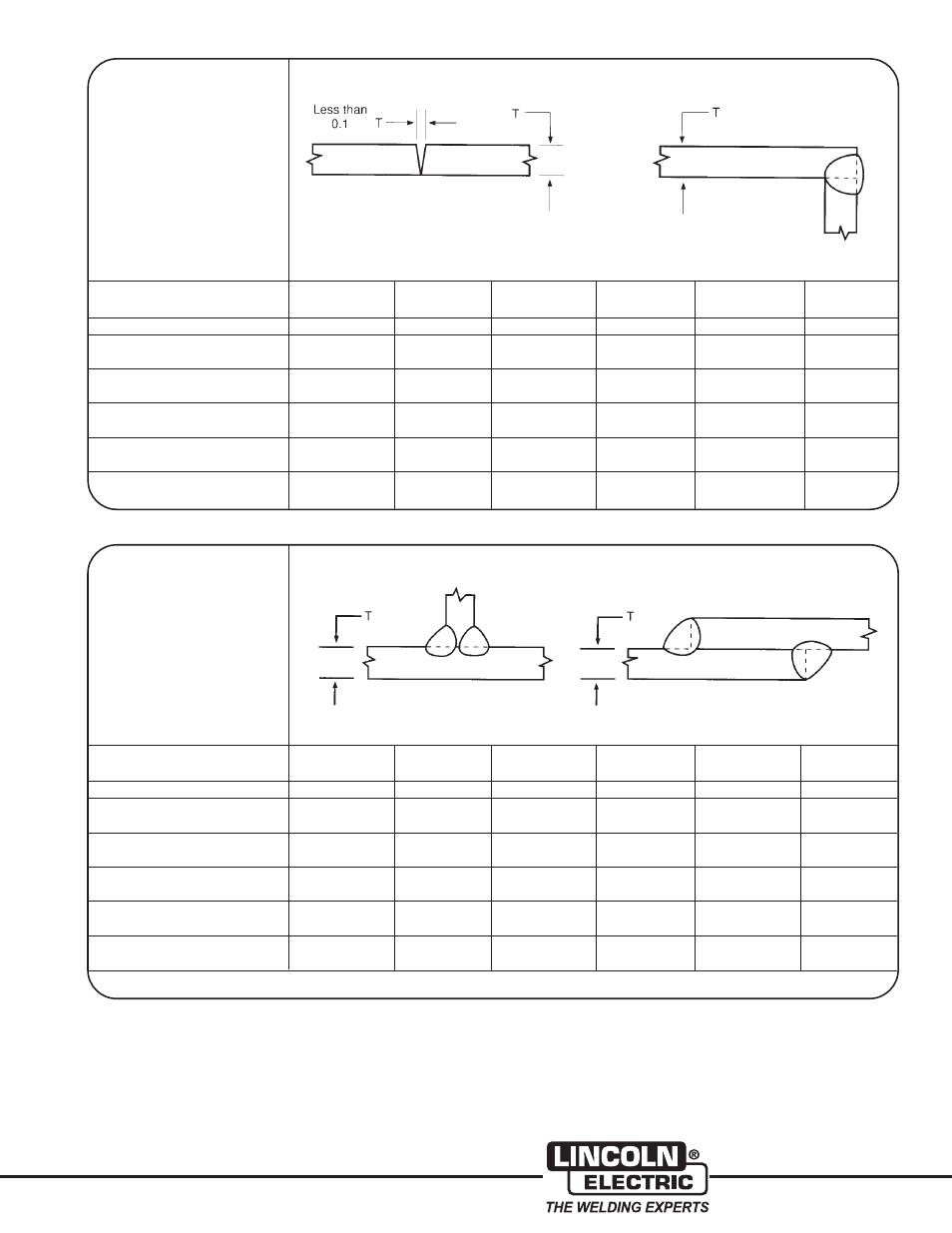

FIGURE 18 — Suggested procedures for GTAW of butt, corner, tee and lap joints in stainless steels.

Plate Thickness, T (in.)

1/16

3/32

1/8

3/16

1/4

1/2

mm.

1.6

2.4

3.2

4.8

6.4

12.7

Current DC(–)

90 - 110

110 - 130

130 - 150

225 - 275

225 - 350

225 - 375

Electrode Diameter (in.)

1/16

1/16

1/16

3/32

1/8

1/8

mm.

1.6

1.6

1.6

2.4

3.2

3.2

Gas Flow, Argon (cfh)

10

10

10

15

20

25

L/min..

4.7

4.7

4.7

7.1

9.4

11.8

Filler-Rod Diameter (in.)

1/16

1/16

3/32

1/8

1/8

1/8

mm.

1.6

1.6

2.4

3.2

3.2

3.2

Arc Speed (ipm)

10

10

10

8

8

8

mm/sec

4.2

4.2

4.2

3.4

3.4

3.4

Total Time (hr/ft of weld)

0.0200

0.0200

0.0200

0.0250

0.0250

0.0250

hr/m. of weld

0.0656

0.0656

0.0656

0.0820

0.0820

0.0820

For vertical-up and overhead, decrease current 10 to 20%.