Lincoln Electric Welder User Manual

Page 28

26

Welding Position: Flat

Weld Quality Level: Code

Steel Weldability: Good

Plate Thickness (in.)

0.078 (14 ga)

0.140 (10 ga)

3/16

1/4

3/8

Plate Thickness

mm.

2.0

3.6

4.8

6.4

9.5

Pass

1

1

1

1

1

2

Electrode Class

E3XX-16, E3XX-17

E3XX-16, E3XX-17

E3XX-16, E3XX-17

E3XX-16, E3XX-17

E3XX-16, E3XX-17

Electrode

Size in.

3/32

1/8

5/32

3/16

3/16

Electrode Size

mm.

2.4

3.2

4.0

4.8

4.8

Current (amp) DC(+)

60

85

125

160

160

175

Arc Speed (in./min.)

14 - 16

12.5 - 13.5

10.5 - 11.5

6.2 - 6.8

6.2 - 6.8

5.7 - 6.3

Arc Speed

mm/sec.

5.9 -6.8

5.3 - 5.7

4.4 - 4.9

2.6 - 2.9

2.6 - 2.9

2.4 - 2.7

Electrode Req’d (lb/ft)

0.028

0.056

0.094

0.22

0.45

Electrode Req’d

kg/m.

0.042

0.083

0.140

0.33

0.67

Total Time (hr/ft of weld)

0.0133

0.0154

0.0182

0.0308

0.0641

Total Time

hrs/m of weld

0.0436

0.0505

0.0597

0.101

0.210

T (in.)

0.04

1/32

3/64

1/16

0

T

mm.

1.0

0.8

1.2

1.6

0

AC can be used with a 10% increase in current. E3XX-15 electrode can be used with a 10% decrease in current.

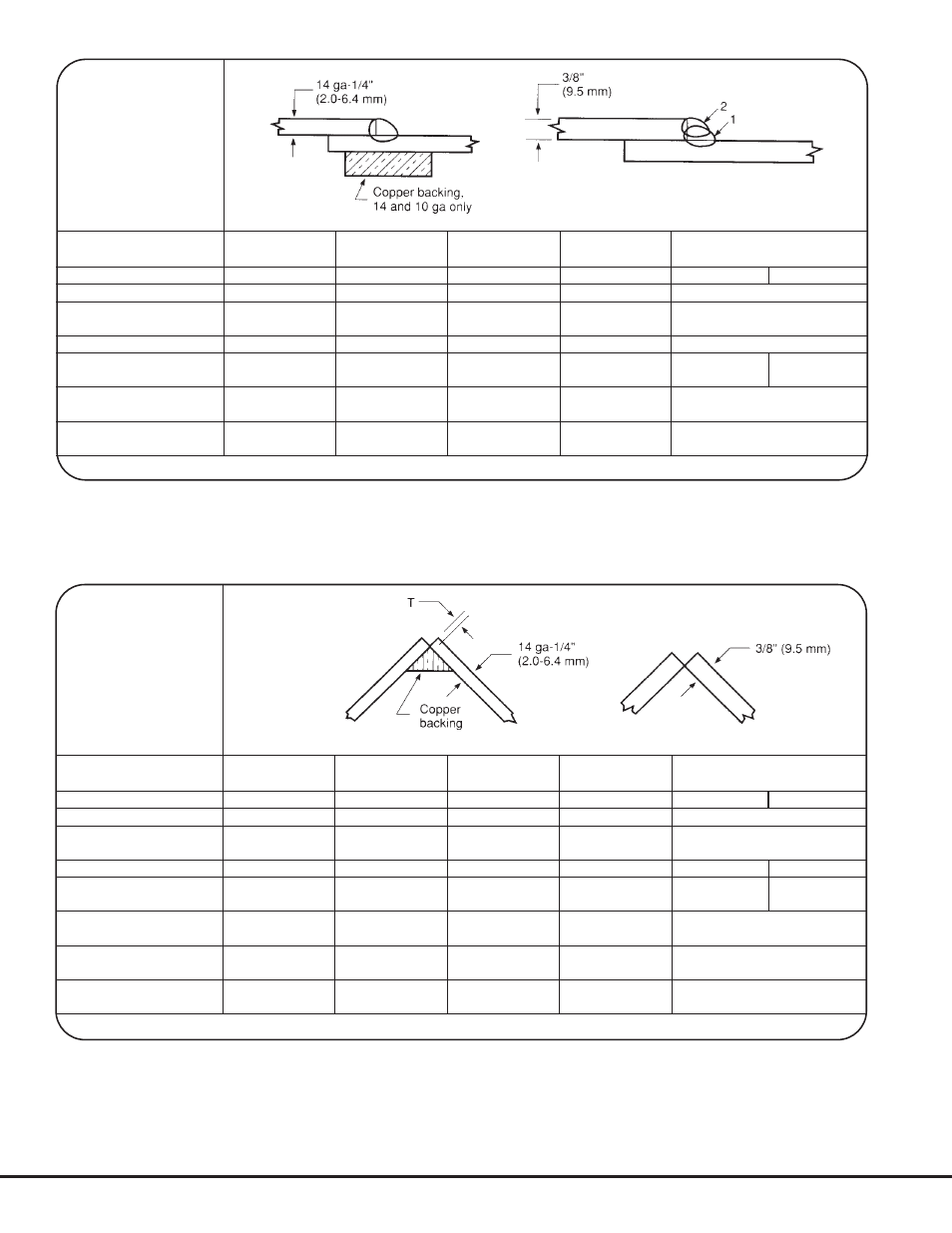

Figure 10 — Suggested procedures for SMAW of corner joints in austenitic stainless steel from

14 gauge (2.0mm) to 3/8 inch (9.5mm) thickness in the flat position.

Welding Position:

Horizontal

Weld Quality Level: Code

Steel Weldability: Good

Plate Thickness (in.)

0.078 (14 ga)

0.140 (10 ga)

3/16

1/4

3/8

Plate Thickness

mm.

2.0

3.6

4.8

6.4

9.5

Pass

1

1

1

1

1

2

Electrode Class

E3XX-16, E3XX-17

E3XX-16, E3XX-17

E3XX-16, E3XX-17

E3XX-16, E3XX-17

E3XX-16, E3XX-17

Electrode

Size in.

3/32

1/8

5/32

3/16

3/16

Electrode Size

mm.

2.4

3.2

4.0

4.8

4.8

Current (amp) DC(+)

60

90

125

170

175

Arc Speed (in./min.)

12.5 - 13.5

12.5 - 13.5

8.6 - 9.4

6.2 - 6.8

6.2 - 6.8

6.7 - 7.3

Arc Speed

mm/sec.

5.3 - 5.7

5.3 - 5.7

3.6 - 4.0

2.6 - 2.9

2.6 - 2.9

2.8 - 3.1

Electrode Req’d (lb/ft)

0.036

0.056

0.130

0.240

0.460

Electrode Req’d

kg/m.

0.054

0.083

0.194

0.357

0.685

Total Time (hr/ft of weld)

0.0154

0.0154

0.0222

0.0308

0.0594

Total Time

hrs/m of weld

0.051

0.051

0.073

0.101

0.195

The notes to fillet weld procedure also apply here.

FIGURE 9 — Suggested procedures for SMAW of lap joints in austenitic stainless steel from

14 gauge (2.0mm) to 3/8 inch (9.5mm) thickness in the horizontal position.