Lincoln Electric Welder User Manual

Page 27

25

Welding Position: Vertical

and Overhead

Weld Quality Level: Code

Steel Weldability: Good

Plate Thickness (in.)

0.078 (14 ga)*

0.140 (10 ga)

3/16

1/4

Plate Thickness

mm.

2.0

3.6

4.8

6.4

Pass

1

1

1

1

2

Electrode Class

E3XX-15

E3XX-15

E3XX-15

E3XX-15

Electrode

Size in.

3/32

1/8

5/32

5/32

Electrode Size

mm.

2.4

3.2

4.0

4.0

Current (amp) DC(+)

50

75

110

110

Arc Speed (in./min.)

14 - 16

6.7 - 7.3

5.2 - 5.8

5.2 - 5.8

4.3 - 4.7

Arc Speed

mm/sec.

5.9 - 6.8

2.8 - 3.1

2.2 - 2.5

2.2 - 2.5

1.8 - 2.0

Electrode Req’d (lb./ft.)

0.030

0.091

0.160

0.370

Electrode Req’d

kg/m.

0.045

0.136

0.238

0.551

Total Time (hr./ft. of weld)

0.0133

0.0286

0.0364

0.0808

Total Time

hrs./m of weld

0.0436

0.0938

0.1194

0.2651

Gap (in.)

0

0

1/16

3/32

Gap

mm.

0

0

1.6

2.4

Root face (in.)

0

0

1/16

1/16

Root face

mm.

0

0

1.6

1.6

*Vertical down, all others vertical up.

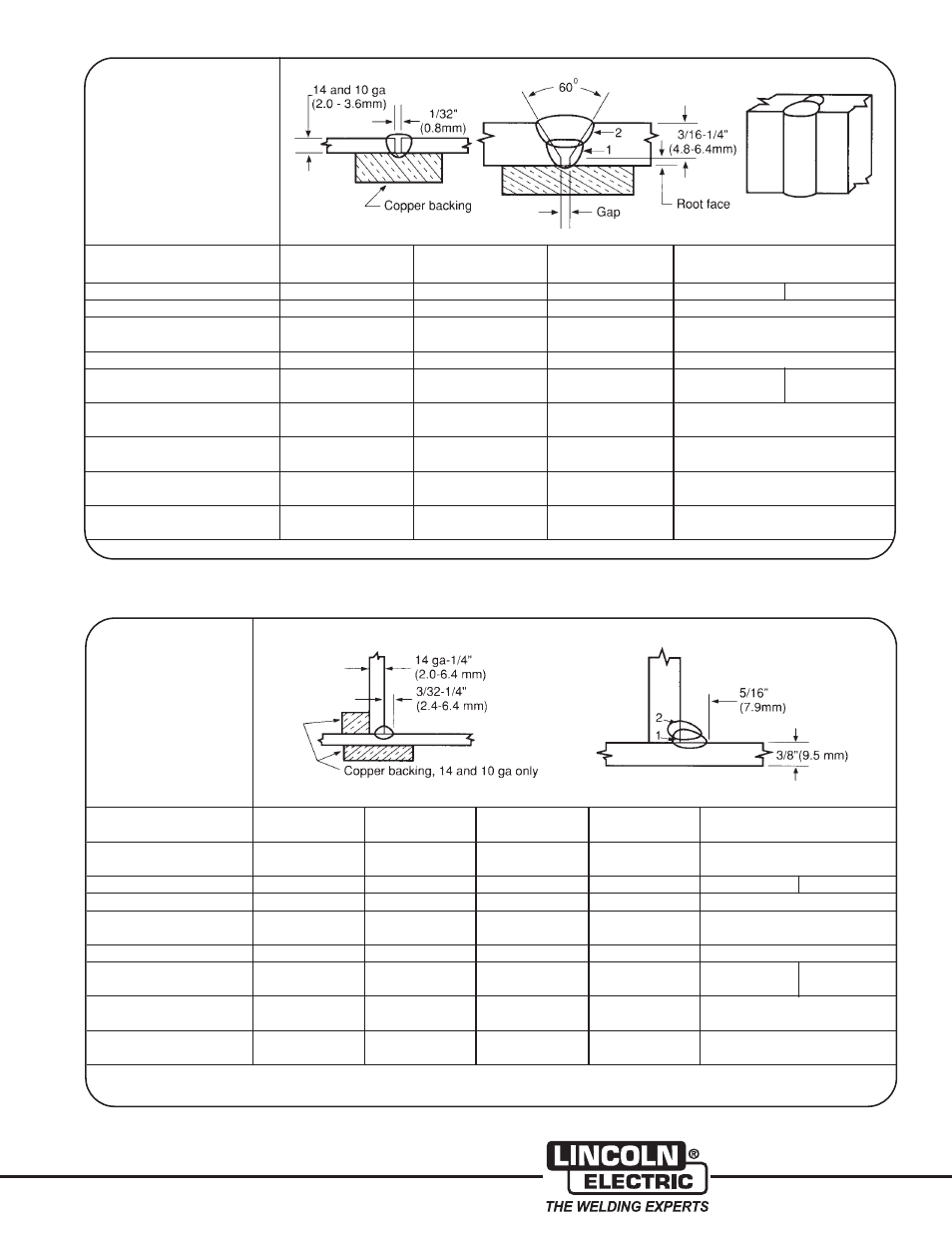

FIGURE 7 — Suggested procedures for SMAW of butt joints in austenitic stainless steel 14 gauge (2.0mm) to

1/4 inch (6.4mm) thickness in the vertical and overhead positions.

Welding Position: Flat or

Horizontal*

Weld Quality Level: Code

Steel Weldability: Good

Weld Size (in.)

3/32

1/8

3/16

1/4

5/16

Weld Size

mm.

2.4

3.2

4.8

6.4

7.9

Plate Thickness (in.)

0.078 (14 ga)

0.140 (10 ga)

3/16

1/4

3/8

Plate Thickness

mm.

2.0

3.6

4.8

6.4

9.5

Pass

1

1

1

1

1

2

Electrode Class

E3XX-16, E3XX-17

E3XX-16, E3XX-17

E3XX-16, E3XX-17

E3XX-16, E3XX-17

E3XX-16, E3XX-17

Electrode

Size in.

3/32

1/8

5/32

3/16

3/16

Electrode Size

mm.

2.4

3.2

4.0

4.8

4.8

Current (amp) DC(+)

60

85

120

160

170

Arc Speed (in./min.)

12.5 - 13.5

12.5 - 3.5

8.6 - 9.4

6.2 - 6.8

6.2 - 6.8

6.7 - 7.3

Arc Speed

mm/sec.

5.3 - 5.7

5.3 - 5.7

3.6 - 4.0

2.6 - 2.9

2.6 - 2.9

2.8 - 3.1

Electrode Req’d (lb/ft)

0.036

0.056

0.120

0.220

0.430

Electrode Req’d

kg/m.

0.054

0.083

0.178

0.328

0.640

Total Time (hr/ft of weld)

0.0154

0.0154

0.0222

0.0308

0.0594

Total Time

hrs/m of weld

0.051

0.051

0.073

0.101

0.195

* For vertical and overhead use same procedures as for vertical and overhead butt welds.

Note: AC can be used with a 10% increase in current. E3XX-15 electrode can be used with a 10% decrease in current.

FIGURE 8 — Suggested procedures for SMAW of fillet joints in austenitic stainless steel from 14 gauge (2.0mm)

to 3/8 inch (9.5mm) thickness in the flat or horizontal positions.