Break-in period, Welding processes stick (constant current) welding, Tig (constant current) welding – Lincoln Electric RANGER IM511-D User Manual

Page 19: Wire feed (constant voltage) welding

Stopping the Engine

Remove all welding and auxiliary power loads and

allow engine to run at low idle speed for a few minutes

to cool the engine.

Stop the engine by placing the “Engine” switch in the

“OFF” position.

A fuel shut off valve is not required on the Ranger 8

because the fuel tank is mounted below the engine.

Break-in Period

It is normal for any engine to use a greater amount of

oil until the break-in is accomplished. Check the oil

level twice a day during the break-in period (approxi-

mately 50 running hours)).

IMPORTANT: IN ORDER TO ACCOMPLISH THIS

BREAK-IN, THE UNIT SHOULD BE SUBJECTED TO

MODERATE LOADS, WITHIN THE RATING OF THE

MACHINE. AVOID LONG IDLE RUNNING PERIODS.

REMOVE LOADS AND ALLOW ENGINE TO COOL

BEFORE SHUTDOWN.

The engine manufacturer’s recommendation for the

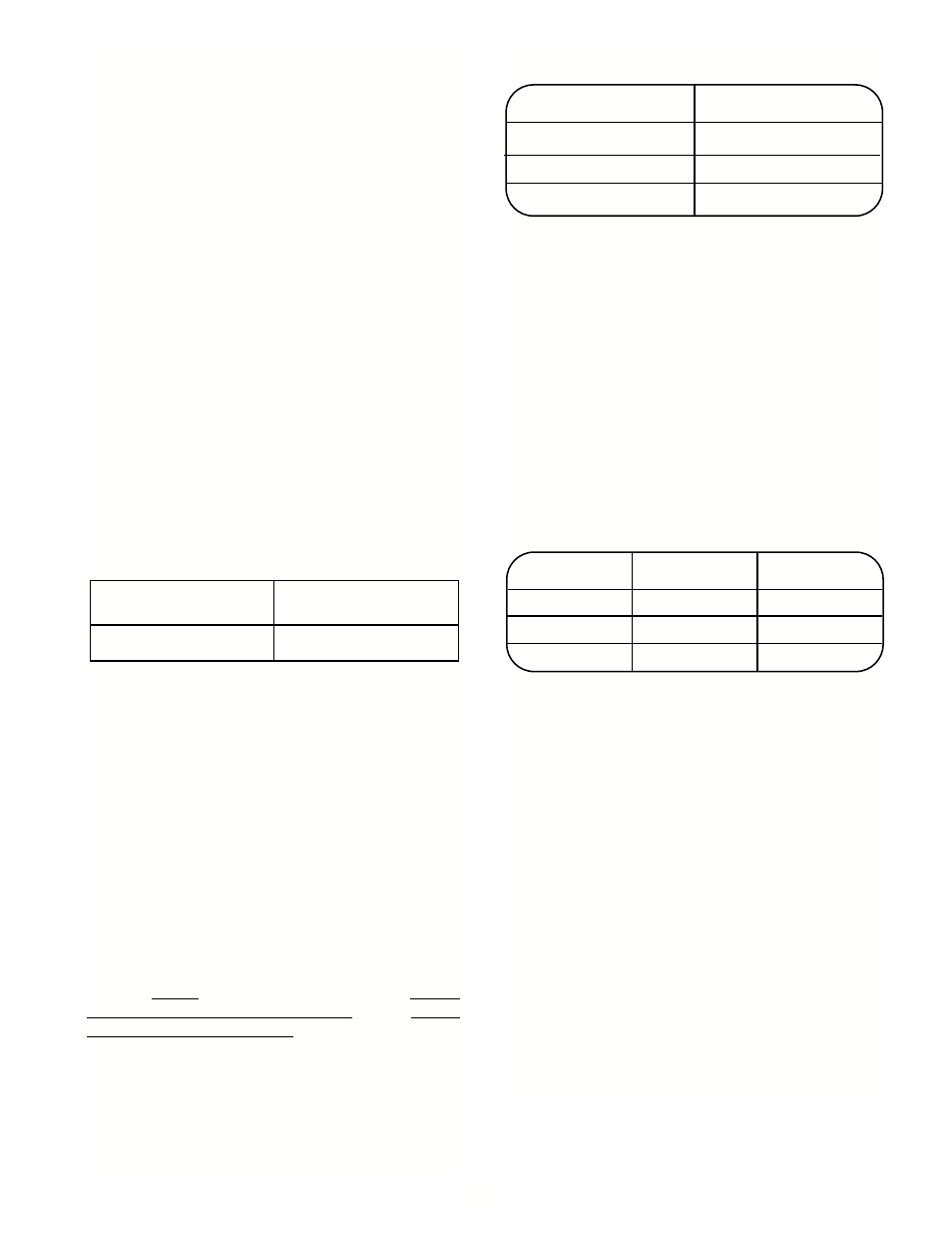

running time until the first oil change is as follows:

The oil filter is to be changed at the second oil change.

Refer to the Engine Owner’s Manual for more informa-

tion.

Welding Processes

Stick (Constant Current) Welding

Connect welding cables to the “TO WORK” and

“ELECTRODE” studs. Start the engine. Set the

"POLARITY” switch to the desired polarity. Set the

output “CONTROL” or remote output control to max

(10) and the “RANGE” switch to the setting that is

closest to the recommended current for the electrode

being used and make a trial weld. A fine adjustment

of the welding can be made by adjusting the output

“CONTROL” or remote control. For the best arc

stability, always use setting that results in the highest

setting of the output or remote control and the lowest

setting of the “RANGE” switch.

The Ranger 9 can be used with a broad range of AC

and DC stick electrodes. See “Welding Tips 1”

included with the Ranger 9 for electrodes within the

rating of this unit and recommended welding currents

of each. See the following table for welding current

ranges:

CURRENT RANGES (AC and DC STICK WELDING

- 5 to 10 ON CONTROL DIAL)

TIG (Constant Current) Welding

The Ranger 9 can be used in a wide variety of AC

and DC Tungsten Inert Gas (TIG) welding applications

for AC TIG welding up to 200 amps and DC TIG

welding up to 250 amps.

The K930-1 TIG Module installed on a Ranger 9

provides high frequency and shielding gas control for

AC and DC GTAW (TIG) welding processes. The TIG

Module allows full range output control. Afterflow time

is adjustable from 0 to 55 seconds.

When using the Ranger 9 for AC TIG welding of

aluminum, the TIG Module is to be set for CONTINU-

OUS HF. The following settings and electrodes are

recommended:

When AC TIG welding, the actual maximum welding

current is 40 to 80 amps higher than the current

marked on the RANGE SWITCH dial. This is a result

of a lower effective reactance due to the natural rectifi-

cation that occurs with the AC TIG welding process.

Wire Feed (Constant Voltage) Welding

The Ranger 9 can be used with a broad range of flux-

cored wire (Innershield and Outershield) electrodes

and solid wires for MIG welding (gas metal arc

welding).

Some recommended Innershield electrodes are:

NR-211MP, NR-311, NR-203 series as well as,

Lincore® 33 and 55 hardfacing electrodes. Diameters

from .035 (0.9mm) up to and including 5/64” (2.0mm)

can be used. 5/64” (2.0mm) NS-3M can be used in

limited applications. Cable length and other condi-

tions can affect the ultimate results of this application.

Request Lincoln publication N-675 for additional infor-

mation.

-17 -

Pure (EWP)

Tungsten Diameter

“Range”

Switch Settings

Welding

Current

1/8

3/32

1/16

90, 120

45, 90

45, 90

100 to 200 amps

45 to 140 amps

45 to 100 amps

RANGE SETTING

ON MACHINE

ACTUAL

CURRENT RANGE

45

90

120

160

200

250

25 to 45 AMPS

50 to 90 AMPS

60 to 120 AMPS

80 to 160 AMPS

100 to 200 AMPS

140 to 250 AMPS

Kohler

CH20S

5 hr

Onan

P218

25 hr