Sensor durability – Kodak I780 User Manual

Page 8

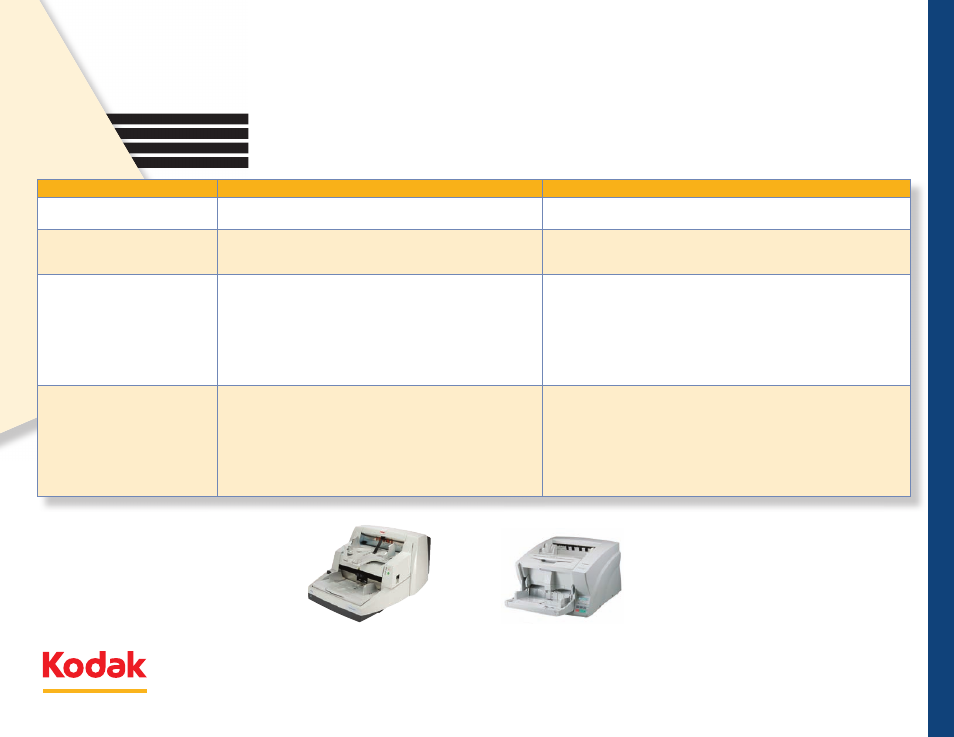

Kodak i780 Scanner vs. Canon DR-X10C Scanner

Fact Check

Canon DR-X10C Scanner

Kodak i780 Scanner

Vendor’s marketing claim

Contact Image Sensor (CIS): “Robust design, outstanding

imaging quality.”

Charge Coupled Device (CCD): “Superior durability and image quality.”

Sensor technology

compare/contrast

CIS array requires that documents come into direct contact

with sensor glass during imaging; this is necessary for the

sensor to capture a quality image.

CCD sensors obtain a quality image without contact between document

and sensor glass.

Sensor placement in

transport path

Real-world scanning jobs, where documents introduce dust, dirt

and staples to the transport path, increase likelihood of damage

to Canon’s Contact Image Sensor during the scanning process.

In the Canon Scanner design, the sensor is encased in glass that

is directly exposed to documents during scanning.

The elegance of Kodak’s CCD sensor design means it is not placed in the

paper path and does not come into contact with documents as they are

scanned and pass through the transport. Instead, via a series of mirrors

that lie above the CCD sensor but beneath the glass barrier viewable

in the paper path, images and data are rapidly captured as documents

pass, while the CCD is protected by the glass barrier or imaging guide.

Additionally, foam guards seal the imaging guide and surround the

mirrors, further preventing contamination.

Impact of sensor technology

on productivity, incidence of

service calls

Direct contact between sensor glass and document originals

increases likelihood of sensor glass damage. With the Canon

DR-X10C Scanner, a service call is needed in order to replace

damaged sensor glass. Uptime and productivity are jeopardized

by Canon’s technological choices.

No contact is required between a document to be scanned and CCD

sensor glass during scanning process, minimizing any chance of risk

to sensor glass surface from staples, dust or dirt on documents. CCD

sensor is located far below paper path and is additionally protected

by a glass barrier known as an “imaging guide” in Kodak i780 Scanner

specifications. Replacement of glass imaging guide, if ever required, can

be completed by end user. Kodak’s intelligent design elements enable

maximum uptime and productivity for customers.

Sensor durability

Kodak’s CCD (Charge Coupled Device) sensor provides enhanced durability over Canon’s CIS (Contact Image Sensor) technology, which requires any document being

Kodak’s CCD (Charge Coupled Device) sensor provides enhanced durability over Canon’s CIS (Contact Image Sensor) technology, which requires any document being

scanned to be in direct physical contact with the sensor glass. As a result, sensor damage is a possibility. CCD sensors do not require contact and produce high-quality

scanned to be in direct physical contact with the sensor glass. As a result, sensor damage is a possibility. CCD sensors do not require contact and produce high-quality

images without close proximity, eliminating the possibility of sensor glass damage due to contact. The

images without close proximity, eliminating the possibility of sensor glass damage due to contact. The

Kodak i780 Scanner is designed to maximize uptime, reduce

service calls and optimize productivity for your operation.

service calls and optimize productivity for your operation.

Kodak i780 Scanner

Canon DR-X10C Scanner

C

ompetitiv

e

B

en

C

hmarking

Count on Kodak for consistent and true performance.

Count out Canon.

©Kodak, 2009. Kodak is a trademark of Kodak.

All testing conducted in quality assurance labs at Kodak’s Document Imaging headquarters facility, 2600 Manitou Road, Rochester, NY from November 18th, 2008 – December 11th, 2008.