Onment, Real-world environment – Kodak I780 User Manual

Page 21

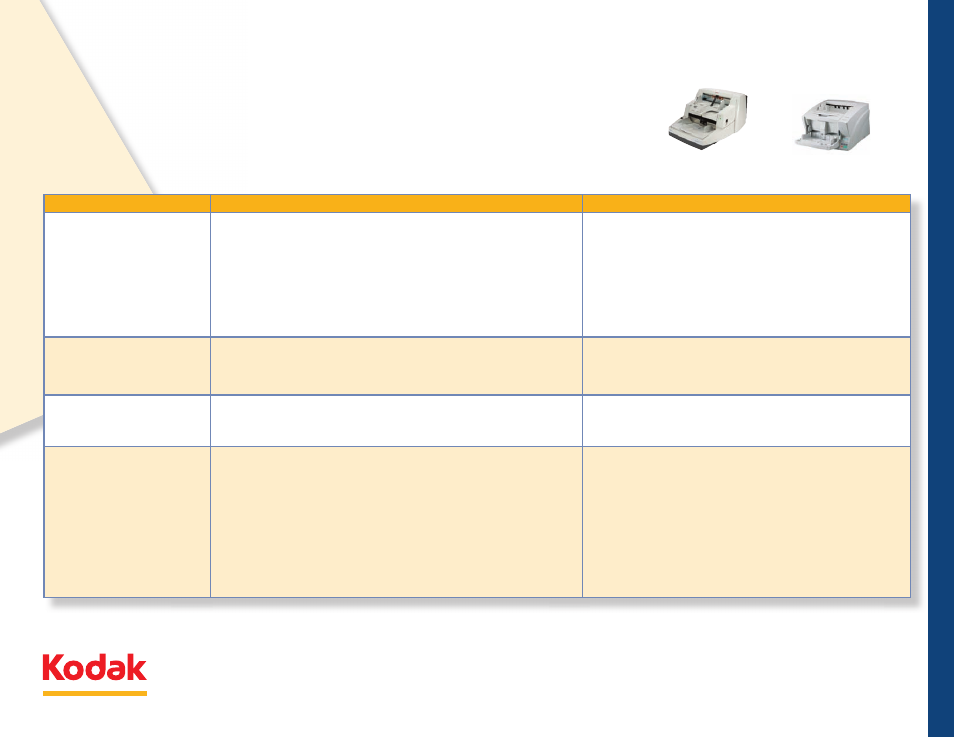

Kodak i780 Scanner vs. Canon DR-X10C Scanner

C

ompetitiv

e

B

en

C

hmarking

Real-world situation

Canon DR-X10C Scanner performance in real-world scanning scenarios

4, 5

Kodak i780 Scanner performance in real-world scenarios

4, 5

Mixed batches—variety of

document weights, sizes and

thicknesses scanned

Any real diversity of documents (checks, envelopes, etc.) throttled

scanner throughput by detecting false misfeeds, unless “misfeed retry”

feature was turned off. A wide document range initiates misfeed detect/

rapid recovery mode, requiring ongoing operator intervention and slowing

down throughput. With misfeed retry feature on, operator had to respond

constantly to scanner control panel error message, as well as resolve

physical document output vs. electronic images saved at the host.

Operator must determine if documents held in tray are only images

not captured.

SurePath paper handling delivered consistent, rated productivity

with ultrasonic double feed detection sensors enabled, and

always fed the image to the host. (A design created with the

operator’s ultimate productivity in mind.) Minimal misfeeding

and jamming during testing. Messaging at host minimized the

“clicks” necessary to clear real misfeeds and quickly restart

the job.

Torque

Canon’s active torque control is not sensitive enough for a variety of

documents, which resulted in bowing and ripping of documents when

speed setting was not adjusted properly for document

types fed.

Kodak’s separation rollers ran fast at initial contact with paper to

smoothly peel document off the top, then returned to a stable

speed—no manual intervention needed.

Standard-size documents

with checks or EKG printouts

attached with tape

Documents viewed as misfeeds, slowing scanner throughput and

requiring operator intervention and resolution at control panel

and host.

Captured images accurately with no productivity loss.

Dust and contaminants

Detected dust and attempted to clear, but streaks still appeared on

images. Confused dust with denser objects, causing scanning to stop.

Auto dust detection occurred only when scanner was first turned on, at

start of job, or coming out of energy saver mode. If dust accumulated

during a job, the scanner did not stop, clean and restart the job,

automatically. (Operator intervention and initiation of dust detection

mid-job resulted in dust being found and cleared in some instances.)

Streaks on images caused by dust accumulation were visible long before

the system auto initiated and cleared dust from the image path.

5

Kodak i780 Scanner’s design focuses on keeping dust away

from optics. CCD sensors are encased in glass and additionally

protected by a glass barrier—known as an imaging guide—and

foam guards to prevent dust from accumulating. No issues with

dust forming on the plate. Blower fans pulled in clean air and

pushed out contaminants and dust (while cooling lamps).

5

Real-world environment

(Mixed Batches/Transport/Reliability/

SurePath/Dust Detection)

A variety of real-world scanning scenarios were created and tested with documents scanned by the Kodak i780 Scanner and Canon DR-X10C Scanner.

4, 5

Count on Kodak for consistent and true performance.

Count out Canon.

©Kodak, 2009. Kodak is a trademark of Kodak.

All testing conducted in quality assurance labs at Kodak’s Document Imaging headquarters facility, 2600 Manitou Road, Rochester, NY from November 18th, 2008 – December 11th, 2008.

Kodak i780 Scanner

Canon DR-X10C Scanner