English, Maintenance work on chassis and engine – KTM Super Duke 990s User Manual

Page 23

ALL MAINTENANCE AND ADJUSTMENT WORK MARKED WITH AN ASTERISK * REQUIRES SPECIAL TECHNICAL SKILLS. IN YOUR OWN INTE-

REST, HAVE THIS WORK PERFORMED BY AN AUTHORIZED KTM WORKSHOP, WHERE YOUR MOTORCYCLE WILL BE SERVICED BY SPECIALLY

TRAINED TECHNICIANS.

– DO NOT CLEAN THE MOTORCYCLE WITH A POWER WASHER OTHERWISE WATER WILL GET INTO THE BEARINGS, ELECTRIC SOCKET CON-

NECTORS, ETC.

– USE SPECIAL KTM SCREWS WITH THE CORRECT THREAD LENGTH TO FASTEN THE SPOILER TO THE TANK. MOUNTING OTHER SCREWS

OR LONGER SCREWS COULD PUNCTURE THE TANK AND CAUSE FUEL TO LEAK OUT.

– IF YOU DISCONNECT SOCKET CONNECTORS WITH SELF-LOCKING NUTS, REPLACE THEM BEFORE REMOUNTING. IF NO NEW SELF-

LOCKING NUTS ARE AVAILABLE, APPLY LOCTITE 243 TO THE THREAD OF THE OLD NUTS. IF THE THREAD IS DAMAGED, REPLACE THE

SCREWS AND NUTS.

– DO NOT USE TOOTHED DISKS OR SPLIT WASHERS FOR THE ENGINE FASTENING BOLTS SINCE THEY WILL WORK THEIR WAY INTO THE

FRAME COMPONENTS AND BECOME LOOSE. ALWAYS USE SELF-LOCKING NUTS.

– LET THE MOTORCYCLE COOL DOWN BEFORE SERVICING TO AVOID BEING BURNED.

– PROPERLY DISPOSE OF OILS GREASE, FILTERS, FUEL, CLEANSERS, ETC. OBSERVE THE REGULATIONS EFFECTIVE IN YOUR COUNTRY.

– NEVER POUR USED OIL IN THE SEWER OR DISPOSE OF IT OUTDOORS. 1 LITER OF USED OIL WILL POLLUTE 1,000,000 LITERS OF WATER.

ENGLISH

22

MAINTENANCE WORK ON CHASSIS AND ENGINE

»

BASIC SETTING

FORK

990 SUPER DUKE

Driving Comfort

Basic Setting

Driving Sport

Maximum Payload

Compression adjuster (clicks)

20

15 10 15

Rebound adjuster (clicks)

20

15 10 15

Spring preload (turns)

5

5 5 6

1

2

2

Adjusting the fork and shock absorber

There are a number of ways to adjust the fork and shock absorber to match

the chassis to your driving style and the payload.

We have provided a table with pragmatical values to help you tune up your

motorcycle. These tune-up specifications are reference values only and should

serve as a basis for your personal chassis and suspension tuning. Do not make

arbitrary changes to the settings (maximum ±40%) since this may impair the

handling characteristics (particularly in the high-speed range).

Make sure both fork legs are equally adjusted.

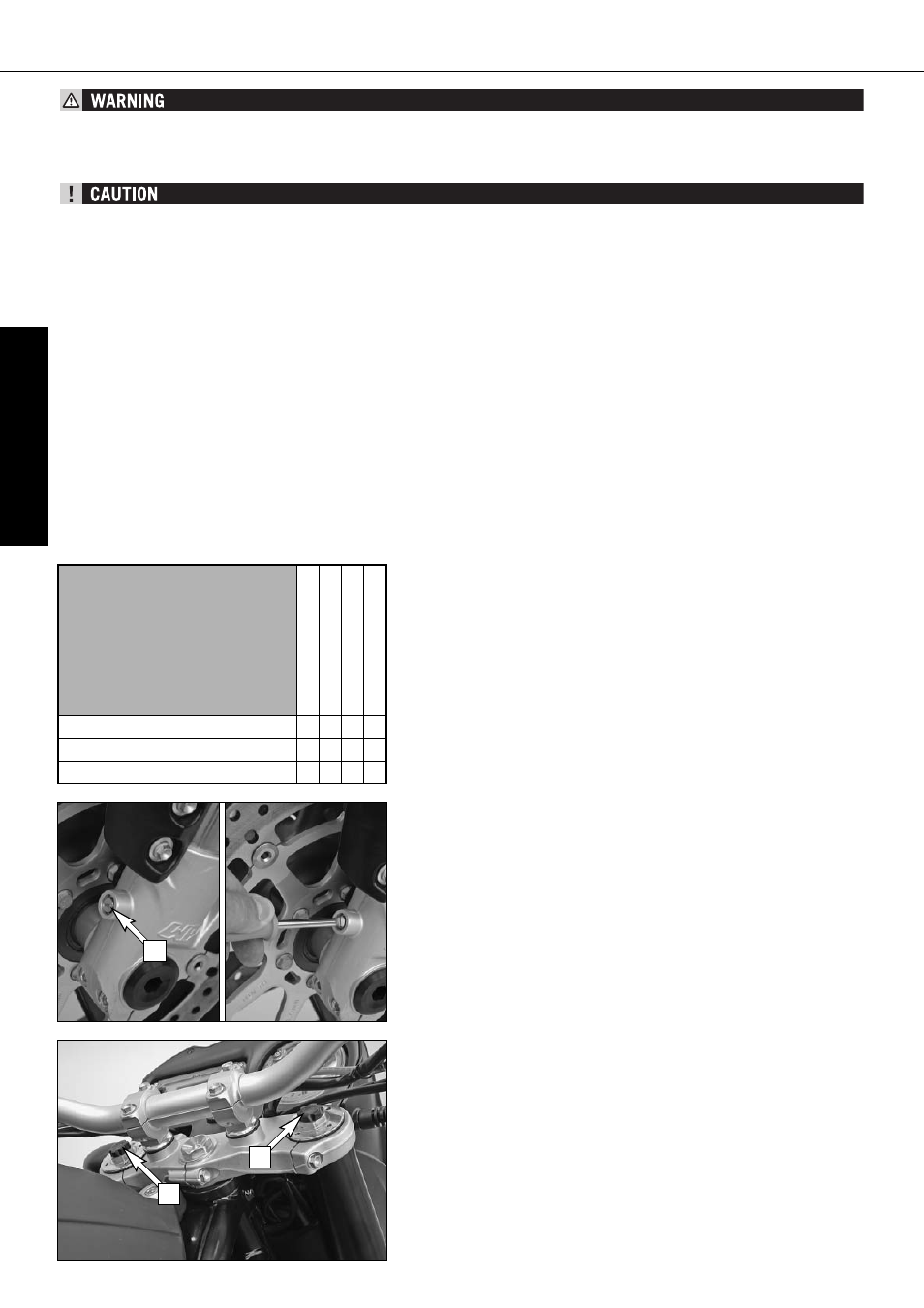

Adjusting compression damping of fork

Hydraulic compression damping determines the reaction when the fork is com-

pressed.

Turn the adjusting screws

[1] clockwise to increase damping, turn it counter-

clockwise to reduce damping during compression.

STANDARD ADJUSTMENT

– Turn adjusting screw clockwise as far as it will go.

– Turn 15 clicks in a counterclockwise direction.

Adjusting rebound damping of fork

Hydraulic rebound damping determines the reaction when the fork is

rebound. By turning the adjusting screw

[2] (REB), the degree of damping of

the rebound can be adjusted. Turn the knob clockwise to increase damping,

turn it counterclockwise to reduce damping during rebounding. Make the same

damping rate adjustment to both fork legs.

STANDARD ADJUSTMENT

– Turn adjusting screw clockwise as far as it will go.

– Turn 15 clicks in a counterclockwise direction.