Scroll chuck clamping, Jaw chuck, Mounting workpiece – Southbend 14" Turn-X Toolroom Lathe SB1039 User Manual

Page 37

For Machines Mfg. Since 5/11

14" TURN-X

®

Toolroom Lathe

-35-

O P E R A T I O N

Scroll Chuck Clamping

This scroll-type chuck has an internal scroll-gear

that moves all jaws in unison when adjusted with

the chuck key. This chuck will hold cylindrical

parts on-center with the axis of spindle rotation

and can be rotated at high speeds if the

workpiece is properly clamped and balanced.

Never mix jaw types or positions to

accommodate an odd-shaped workpiece.

The chuck will spin out of balance and

may throw the workpiece! Instead, use an

independent jaw chuck or a faceplate.

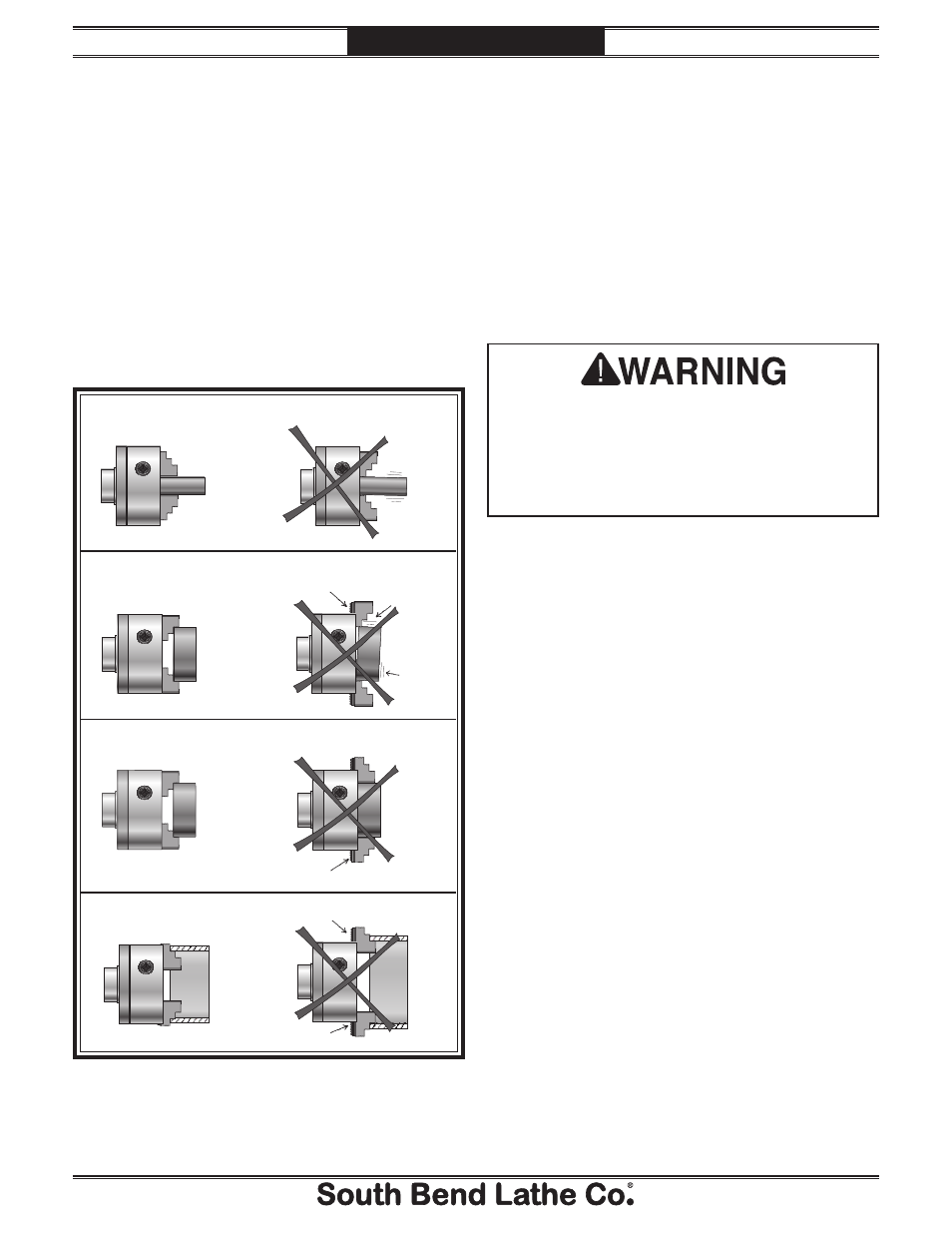

Figure 35. Jaw selection and workpiece holding.

Insufficient

Jaw Clamping

Unstable

Workpiece

Bar Stock

Inside

Safer

Use

Jaw

Cylinder

Unsafe Jaw Position

Poor Scroll

Gear Engagement

Inside

Safer

Use

Jaw

Shallow

Bar Stock

Inside

Unsafe

Use

Jaw

Poor Scroll Gear Engagement

Unsafe Jaw Position and

Outside

Safer

Use

Jaw

Poor Scroll Gear Engagement

Unsafe Jaw Position and

Poor

Unstable

Workpiece

Shallow

Bar Stock

Outside

Safer

Use

Jaw

Grip

4-Jaw Chuck

Refer to the Chuck Installation (see Page 33)

and Chuck Removal (see Page 34) instructions

to install or remove the 4-jaw chuck.

The 4-jaw chuck features independently

adjustable hardened steel jaws for holding non-

concentric or off-center workpieces. Each jaw can

be independently removed from the chuck body

and reversed for a wide range of work holding

versatility.

Mounting Workpiece

1. DISCONNECT LATHE FROM POWER!

2. Place a chuck cradle or plywood on the

bedway below the chuck to protect the

bedway surfaces.

3. Use the chuck key to open each jaw so the

workpiece will lay flat against the chuck

face, jaw steps, or into the spindle opening.

4. With help from another person or a holding

device, position the workpiece so it is

centered in the chuck.

Because of the dynamic forces involved in

machining a non-concentric or off-center

workpiece, always use a low spindle speed

to reduce risk of the workpiece coming loose

and being thrown from the lathe, which could

cause death or serious personal injury.