Af`ek`e – Woodstock W1814 User Manual

Page 26

-24-

N(/(+Fne\ijDXelXcD]^%('&'/"

FG

<

I

8

K@FEJ

<[^\Af`ek`e^

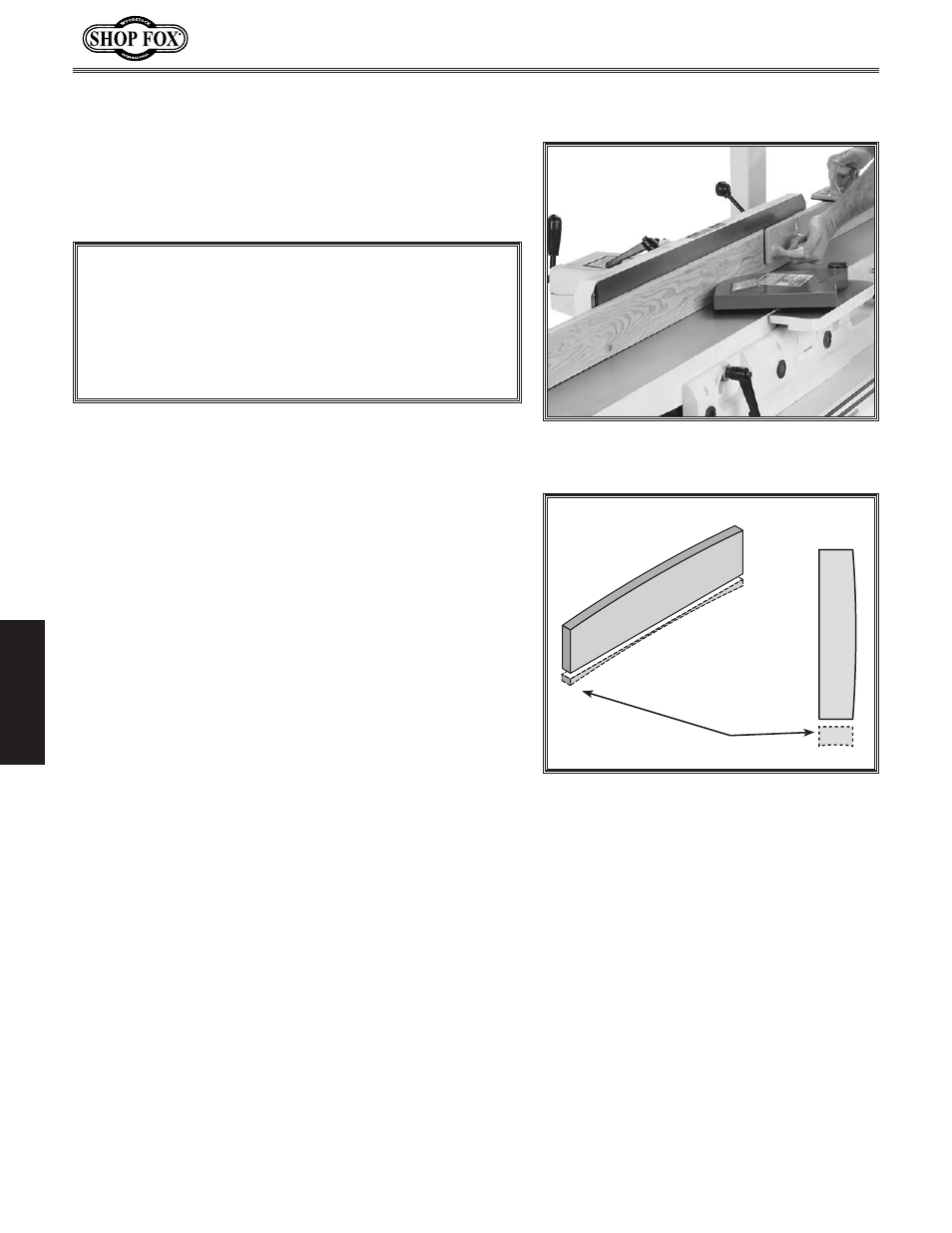

The purpose of edge jointing is to produce a finished,

flat-edged surface (see

=`^li\j*-&*.) that is suitable

for joinery or finishing. It is also a necessary step when

squaring rough or warped stock.

Kf\[^\af`ekfek_\af`ek\i#[fk_\j\jk\gj1

(% Read

and

understand

J8=

)% Make sure your stock has been inspected for danger-

ous conditions as described in the

JkfZb@ejg\Zk`fe

I\hl`i\d\ekj instructions, beginning on GX^\)(.

*% Set the cutting depth for your operation. Efk\1 N\

jl^^\jkY\kn\\e

(

Ð

(-

Xe[

(

Ð

/

]fi\[^\af`ek`e^#

lj`e^Xdfi\j_Xccfn[\gk_]fi_Xi[nff[jg\Z`\jfi

]fin`[\jkfZb.

+% Make sure the fence is set to 90˚.

,% If your workpiece is cupped (warped), place it so the

concave side is face down (

=`^li\*.) on the surface

of the infeed table.

-% Start

the

jointer.

.% Press the workpiece against the table and fence with

firm pressure. Use your trailing hand to guide the

workpiece through the cut, and feed the workpiece

over the cutterhead (see

=`^li\*-).

Efk\: @]pflic\X[`e^_Xe[^\kjn`k_`e+f]k_\

Zlkk\i_\X[#c`]k`klgXe[fm\ik_\Zlkk\i_\X[#Xe[

gcXZ\`kfek_\gfik`fef]k_\nfibg`\Z\k_Xk`jfm\i

k_\flk]\\[kXYc\%Efn#]fZljpfligi\jjli\fek_\

flk]\\[\e[f]k_\nfibg`\Z\n_`c\]\\[`e^#Xe[

i\g\Xkk_\jXd\XZk`fen`k_pflikiX`c`e^_Xe[`]`k

^\kjn`k_`e+f]k_\Zlkk\i_\X[%Kfb\\gpfli_Xe[j

jX]\#;FEFKc\kk_\d^\kZcfj\ik_Xe+]ifdk_\

Zlkk\i_\X[n_\e`k`jdfm`e^

/% RepeatJk\g. until the entire edge is flat.

@] pfl Xi\ efk \og\i`\eZ\[ n`k_ X af`ek\i# j\k

k_\ [\gk_ f] Zlk kf '# Xe[ giXZk`Z\ ]\\[`e^ k_\

nfibg`\Z\ XZifjj k_\ kXYc\j Xj [\jZi`Y\[ Y\cfn%

K_`j gifZ\[li\ n`cc Y\kk\i gi\gXi\ pfl ]fi k_\

XZklXcfg\iXk`fe%

EFK@:<

=`^li\*-% Typical edge jointing operation.

=`^li\*.%Illustration of edge jointing

results.

Portion

Removed with

Jointer