Carriage controls – Southbend South Bend 16 SPEED GEARHEAD LATHE SB1053 User Manual

Page 9

For Machines Mfg. Since 3/11

16-Speed Gearhead Lathe

-7-

I N T R O D U C T I O N

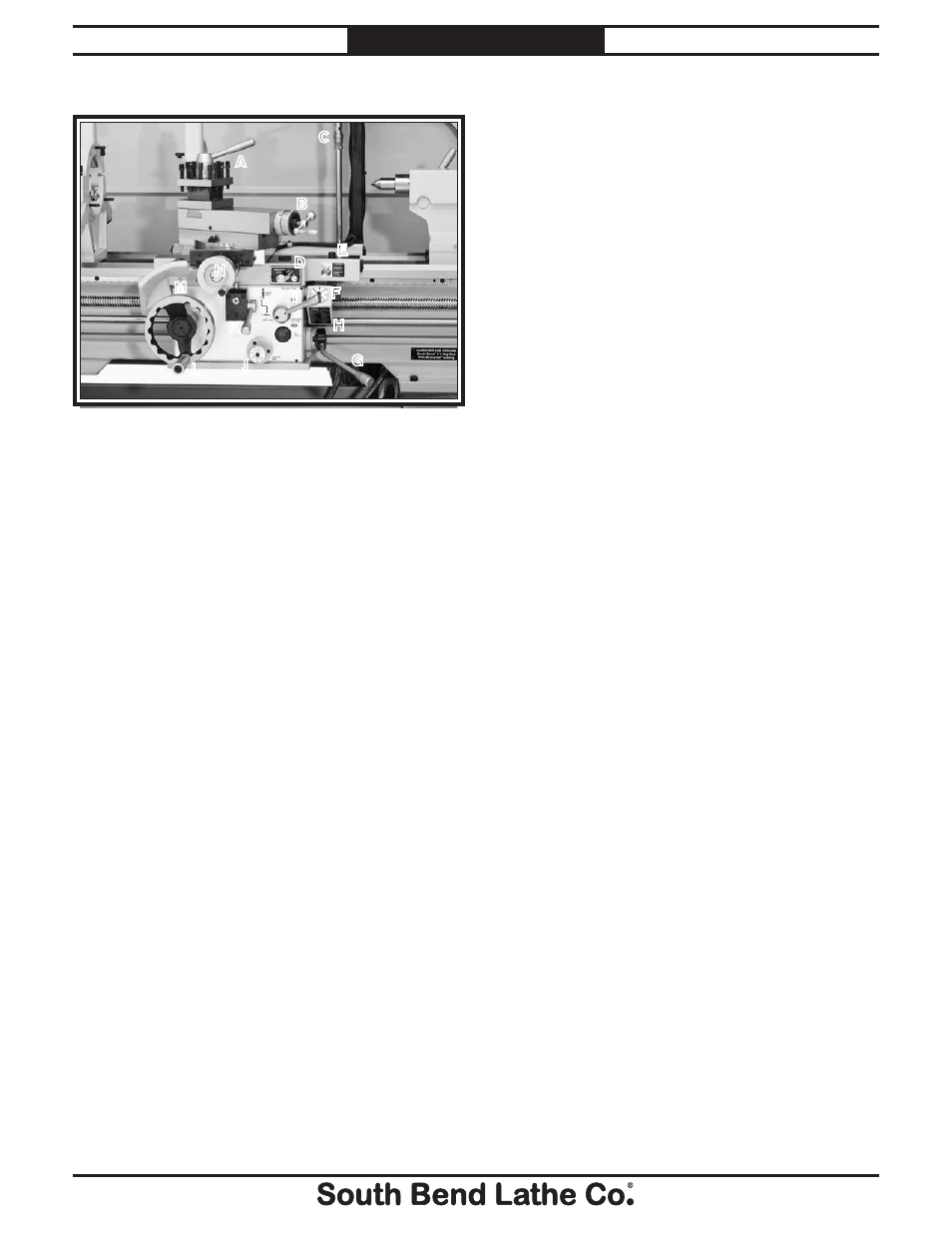

A. 4-Position Tool Post Lever:

Locks the tool

holder in four possible positions.

B. Compound Rest Handwheel:

Moves the

cutting tool back and forth relative to

the workpiece. Includes an indirect-read

graduated dial, which represents actual tool

movement.

C. Coolant Valve Lever:

Controls the flow of

coolant from the nozzle.

D. One-Shot

Oiler:

Draws oil from the apron

reservoir and lubricates the bed ways

underneath the saddle.

E. Carriage Lock Bolt:

Secures the carriage in

place for greater rigidity and accuracy when

using the cross slide or compound rest for

machining operations.

Figure 8. Carriage controls.

A

C

B

E

D

F

G

I

J

K

L

N

M

H

F. Thread

Dial:

Indicates when to engage the

half nut during inch threading operations.

G. Spindle ON/OFF Lever:

Starts, stops and

reverses direction of spindle rotation.

H. Thread Dial Chart:

For each inch thread,

displays which number on the thread dial to

engage the half nut.

I.

Half Nut Lever:

Engages and disengages the

half nut for threading operations.

J.

Quick-Change Feed Direction Knob:

Changes

direction of carriage feed or the cross slide

feed without having to stop the lathe and

move the headstock feed direction lever.

K. Feed Control Lever:

Engages and disengages

the cross slide or carriage feed.

L. Carriage

Handwheel:

Moves the carriage

manually along the bed.

M. Apron:

Houses the carriage gearing and

controls.

N. Cross Slide Handwheel:

Moves the cross

slide toward or away from the workpiece.

Includes a direct-read graduated dial, which

represents half the amount of tool movement

and the total amount of material removed

from the diameter of the workpiece.

Carriage Controls