Faceplate – Southbend South Bend 16 SPEED GEARHEAD LATHE SB1053 User Manual

Page 40

-38-

For Machines Mfg. Since 3/11

16-Speed Gearhead Lathe

O P E R A T I O N

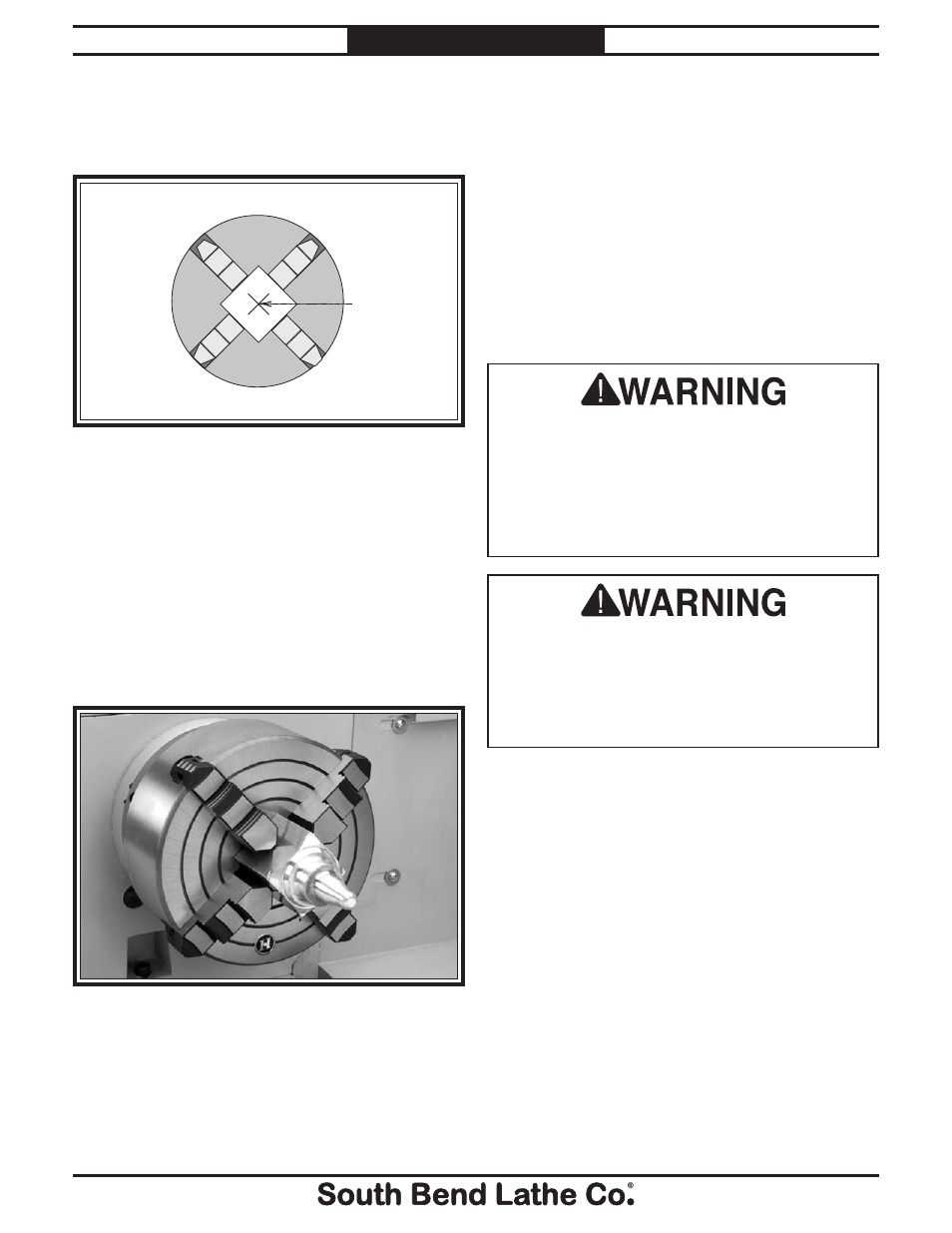

Figure 43. 4-jaw tightening sequence.

1

2

3

4

Workpiece

Centerpoint

5.

Tighten each jaw in small increments. After

you have adjusted the first jaw, continue

tightening in an opposing sequence, as

shown in Figure 43.

6.

After the workpiece is held in place by

the jaws, turn the chuck by hand and pay

attention to the workpiece alignment.

— If the workpiece is not correctly aligned

for your operation as you turn the chuck,

make fine adjustments by slightly

loosening one jaw and tightening the

opposing jaw until the workpiece is

correctly aligned (see Figure 44 for an

example).

Figure 44. Example photo of non-cylindrical workpiece

correctly mounted on the 4-jaw chuck.

Faceplate

Refer to the Chuck Installation (Page 35) and

Chuck Removal (Page 36) instructions to

install or remove the faceplate.

The 12" faceplate included with your lathe offers

a wide range of uses, including machining non-

concentric workpieces, straight turning between

centers, off-center turning, and boring.

The tools needed for mounting a workpiece will

vary depending on the type of setup you have.

Machining non-concentric workpieces at a

high speed could cause the workpiece to be

thrown from the spindle with deadly force at

the operator or bystanders. To reduce this

risk, only machine non-concentric workpieces

at low speeds and clamp counter-weights to

the faceplate to balance it.

Failure to properly secure a workpiece to the

faceplate could cause the workpiece to be

thrown from the lathe with deadly force at the

operator or bystanders. Use a minimum of

THREE independent clamping devices to hold

the workpiece onto the faceplate.