Southbend South Bend SB1042PF User Manual

Page 85

For Machines Mfg. Since 3/11

Turn-Nado

®

EVS Lathes

-83-

S E R V I C E

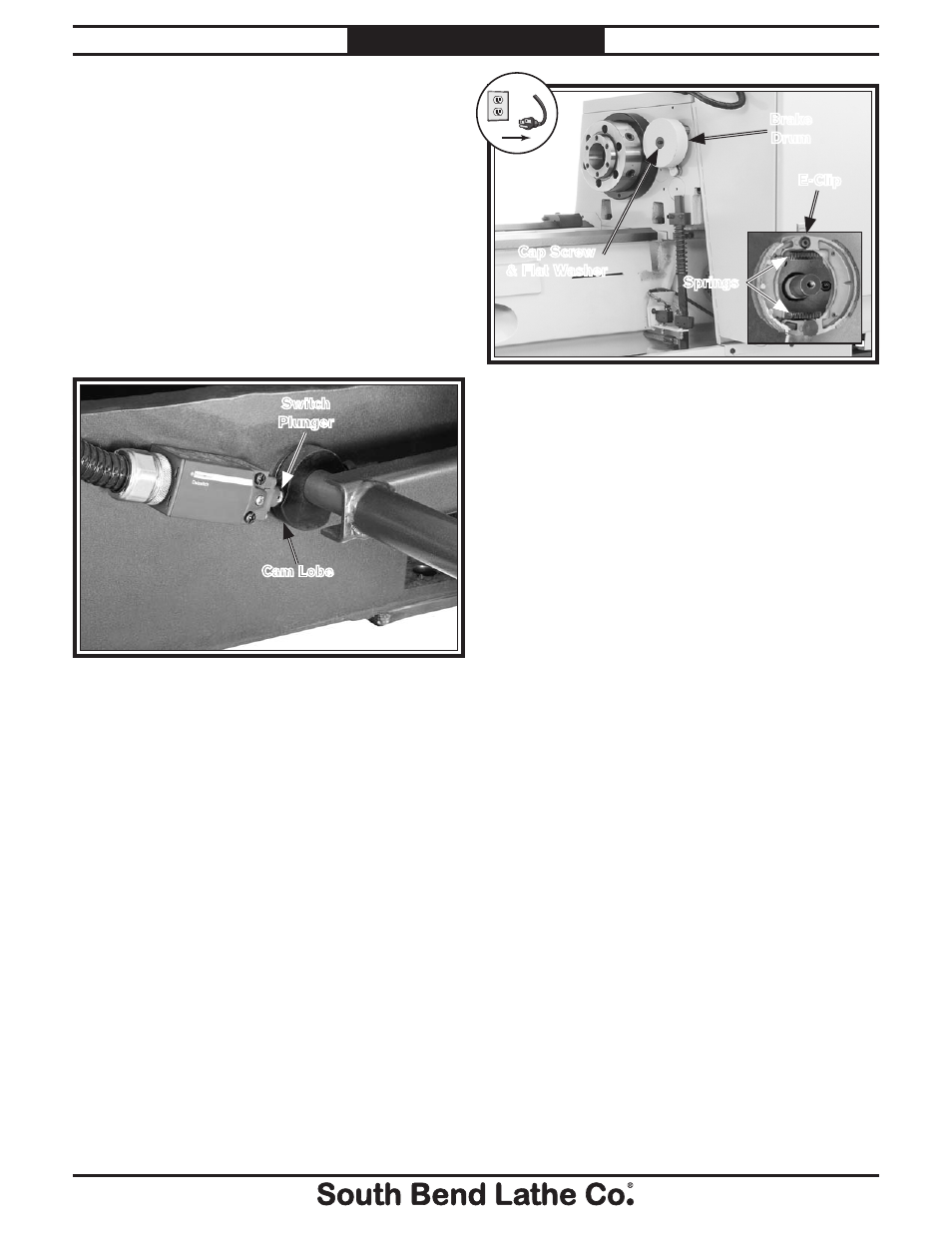

6.

Have another person step on the brake pedal

while you verify that the cam lobe shown in

Figure 129 makes the brake switch plunger

click in.

— If the switch does not click, loosen the two

switch mounting screws, push the pedal

all the way down, and move the switch

closer to the lobe until it clicks. Secure the

switch in place at this location.

With the foot pedal released, the switch

plunger should be approximately 3mm

from the lobe.

Figure 129. Brake switch.

Cam Lobe

Switch

Plunger

7.

Have another person press and release the

brake pedal a few times while you watch for

loose linkage fasteners or worn pivot points.

Tighten or replace parts as necessary.

8.

While the brake pedal is being held down

to lock the brake drum in place, remove the

drum retaining cap screw and flat washer

shown in Figure 130.

9.

Use mineral spirits and a rag to clean the

drum, then inspect it.

— If the drum is bell-mouthed, cracked, or

shows deep grooves, replace it. For minor

scoring, the drum can be dressed with

sandpaper or turned on a lathe.

Figure 130. Brake drum.

Brake

Drum

Cap Screw

& Flat Washer

E-Clip

Springs

10.

Remove the E-clip and springs shown in the

inset of Figure 130, then remove the brake

shoes.

11.

Clean the brake shoes with hot soapy water,

then inspect them and measure the brake

lining thickness.

— If the lining is

3

⁄

16

" or less or if the lining is

damaged, replace the brake shoes as a set.

12.

Replace the brake drum cover, backsplash,

and chuck guard before re-connecting the

lathe to power.

!