Tailstock, Positioning tailstock, Using quill – Southbend South Bend SB1042PF User Manual

Page 44

-42-

For Machines Mfg. Since 3/11

Turn-Nado

®

EVS Lathes

O P E R A T I O N

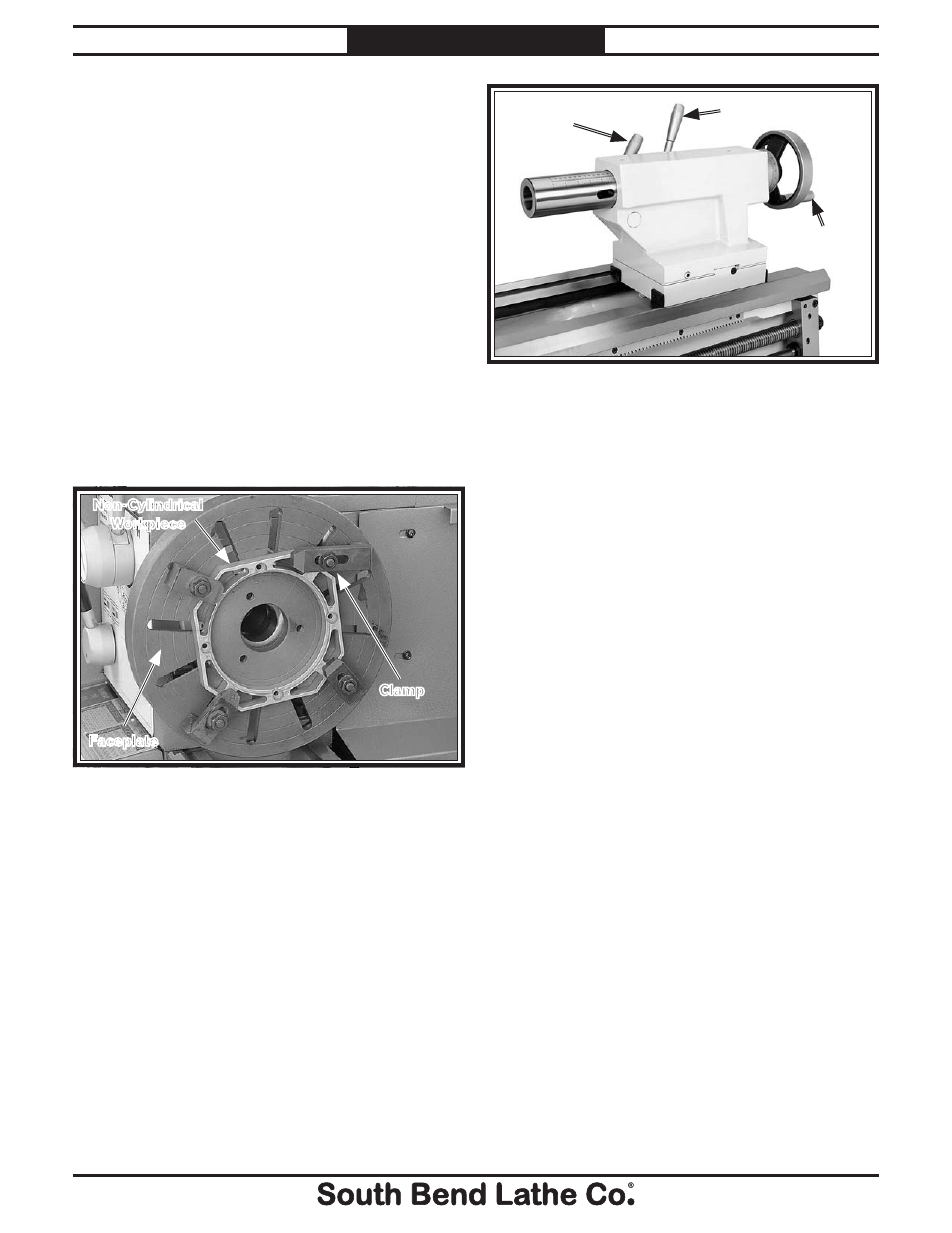

To mount a non-concentric workpiece to the

faceplate:

1.

DISCONNECT LATHE FROM POWER!

2.

Protect the bedway with a piece of plywood.

3.

With help from another person or a holding

device to support the workpiece, position it

onto the faceplate and clamp it in place with

a minimum of three independent clamping

devices (see Figure 39 for an example).

Be sure to take into account the rotational

and cutting forces that will be applied to the

workpiece when clamping it to the faceplate.

If necessary, use counter-weights to balance

the assembly and use a dial indicator to

make sure that the workpiece is properly

positioned for your operation.

Graduated Dial

Increments .....................................................0.001"

One Full Revolution ......................................0.100"

Increments on Quill

Inch .................................... 0"-6" in

1

⁄

8

" Increments

Metric ..................... 0–160mm in 1mm Increments

Positioning Tailstock

1.

Pull the tailstock lock lever backward (away

from the spindle) to unlock the tailstock from

the bedway.

2.

Slide the tailstock to the desired position.

3.

Push the tailstock lock lever forward (toward

the spindle) to lock the tailstock against the

bedway.

Using Quill

1.

Move the quill lock lever toward the spindle

to unlock the quill.

2.

Turn the tailstock handwheel clockwise

to move the quill toward the spindle or

counterclockwise to move it away from it.

3.

Move the lock lever away from the spindle to

secure the quill in place.

Tailstock

The tailstock (see Figure 40) is typically used

to support long workpieces by means of a live or

dead center (refer to Centers on Page 46). It

can also be used to hold a drill or chuck to bore

holes in the center of a part. Custom arbors and

tapers can also be cut on your lathe by using the

offset tailstock adjustment.

Figure 39. Example photo of workpiece clamped in a

faceplate.

Clamp

Faceplate

Non-Cylindrical

Workpiece

Figure 40. Tailstock and quill lock levers in locked

position.

Quill Lock

Lever

Tailstock

Handwheel

Tailstock Lock Lever