Chip drawer, Coolant system – Southbend South Bend SB1042PF User Manual

Page 65

For Machines Mfg. Since 3/11

Turn-Nado

®

EVS Lathes

-63-

O P E R A T I O N

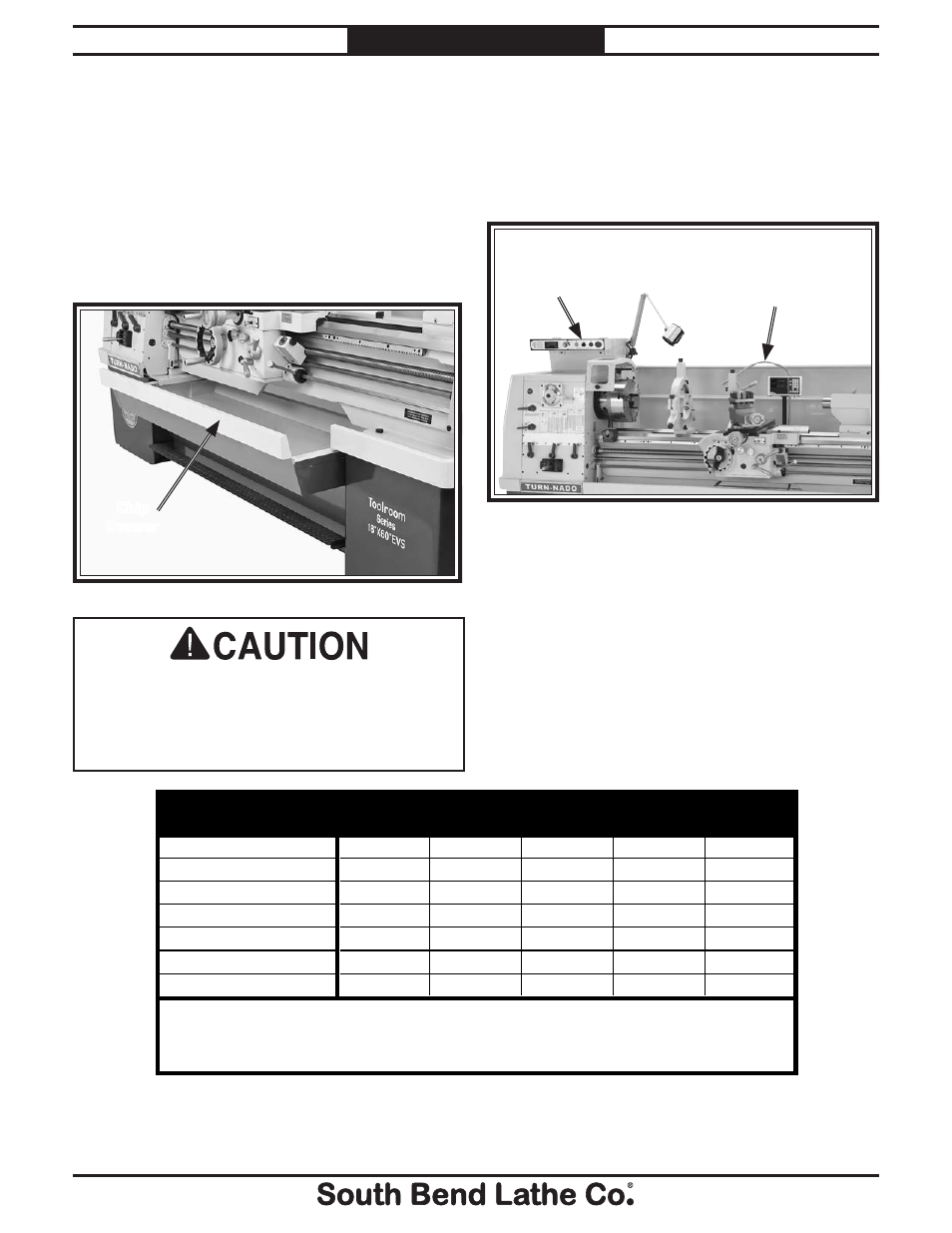

The chip drawer catches swarf and metal chips

during the machining process. It contains a

screen that keeps the large chips from returning

to the reservoir with the run-off coolant—this

prevents the chips causing pump damage.

Also, it slides open and is removable for cleaning

(see Figure 89).

Chip Drawer

Always use high quality coolant and follow the

manufacturer's instructions for diluting and

maintenance. The quick reference table shown

in Figure 91 can help you select the appropriate

fluid.

Refer to Coolant System Service on Page 75

for detailed instructions on how to add or change

fluid. Check the coolant regularly and promptly

change it when it becomes overly dirty or rancid,

or as recommended by the fluid manufacturer.

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Aluminum

Brass

Bronze

Cast iron

Low Carbon Steel

Alloy Metals

Stainless Steel

General Note:

Coolants are used for heavy-duty lathe operations and production turning. Oil-water

emulsions and synthetic cutting fluids are the most common for typical lathe operations. Sulferized oils

often are used for threading. For small projects, spot lubrications can be done with an oil can or brush, or

omitted completely.

Workpiece

Dry

Water

Soluble Oil

Synthetic

Coolants

Sulferized

Oil

Mineral

OIl

Figure 91. Coolant selection table.

Coolant System

When the coolant pump switch is turned ON, the

fluid is delivered through the nozzle attached to

the carriage. The flow is controlled by the valve

lever at the base of the nozzle (see Figure 90).

Figure 90. Coolant system controls.

Coolant

Pump Switch

Nozzle

& Valve

Lever

The chip drawer is very heavy. Unless

removing the chip drawer for cleaning, do

not pull it out more than halfway to prevent it

falling and causing impact injuries. If removing

the drawer for cleaning, get assistance!

Figure 89. Chip drawer.

Chip

Drawer