Brake service – Southbend South Bend SB1042PF User Manual

Page 84

-82-

For Machines Mfg. Since 3/11

Turn-Nado

®

EVS Lathes

S E R V I C E

Brake Service

The brake linkage on this lathe is not adjustable.

As pivot points wear, the increased play in

the linkage absorbs the usable stroke that is

required for full brake application.

If the brake does not stop the lathe quickly,

verify that the linkage is not excessively worn or

damaged and that all fasteners are tight before

replacing the brake shoes.

Needed: Qty

Another Person ..................................................... 1

Hex Wrench 6mm ................................................. 1

Hex Wrench 8mm ................................................. 1

Needle-Nose Pliers ................................................ 1

Basic Calipers ....................................................... 1

Safety Goggles .......................... 1 for Each Person

Approved Respirator ................. 1 for Each Person

To replace the brake shoes:

1.

DISCONNECT LATHE FROM POWER!

2.

Put on a respirator and eye protection to

protect yourself from hazardous brake dust.

3.

With the help of another person, remove

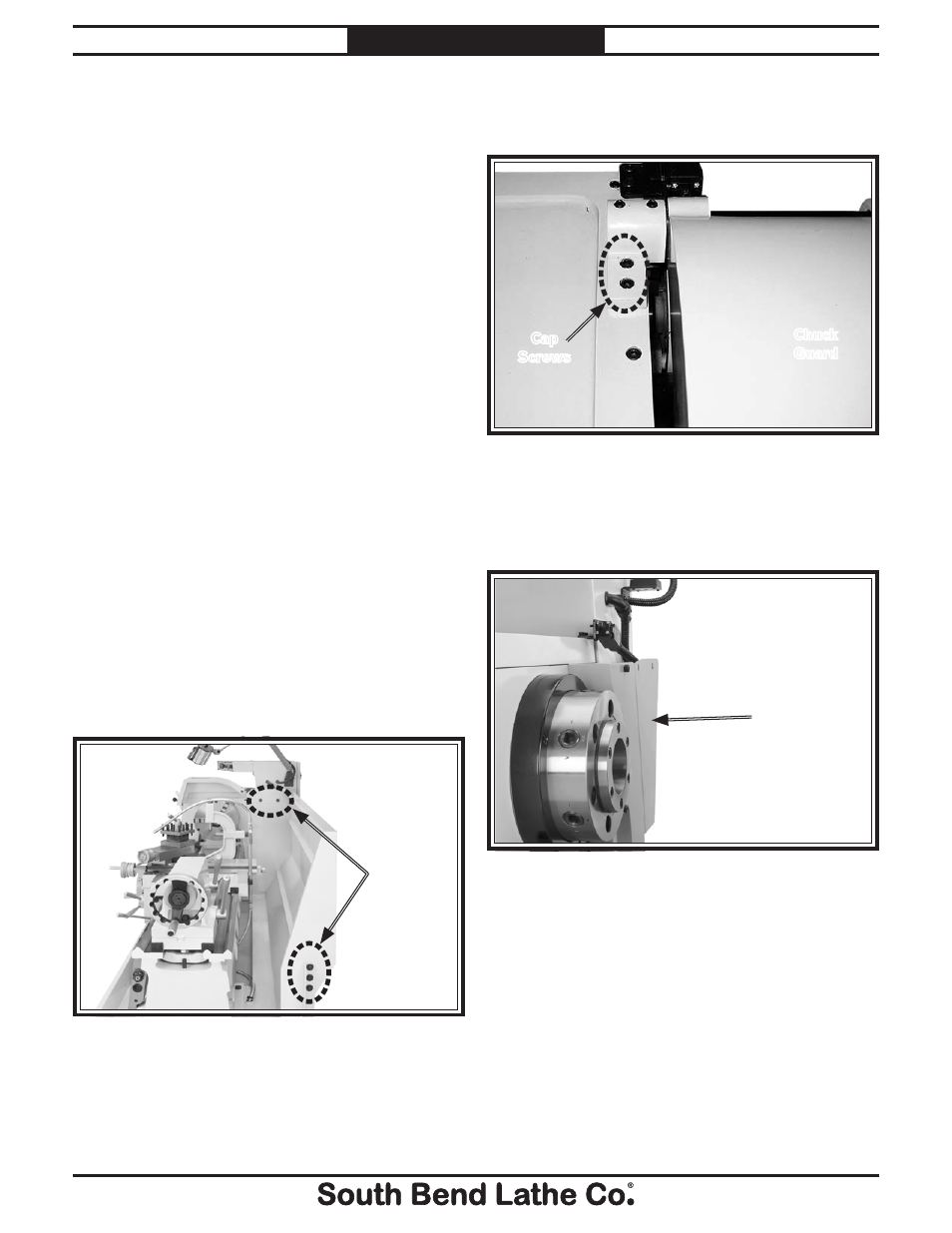

the splash guard. See Figure 126 for the

locations of the cap screws that secure the

backsplash.

Figure 126. Locations of the backsplash cap screws.

Cap

Screws

4.

Remove the two cap screws that secure the

chuck guard to the top of the headstock (see

Figure 127), then remove the guard.

Figure 127. Location of cap screws securing the chuck

guard.

Chuck

Guard

Cap

Screws

5.

If installed, remove the chuck from the

spindle, then remove the brake drum cover

(see Figure 128).

Figure 128. Brake drum cover.

Brake Drum

Cover