Labels, Envelopes – Samsung CLP-300 Series User Manual

Page 50

Specifications

8.4

• Condition: Envelopes should not be wrinkled, nicked, or

otherwise damaged.

• Temperature: You should use envelopes that are compatible

with the heat and pressure of the printer.

• Size: You should only use envelopes within the following size

ranges.

N

OTE

: You may experience some paper jams when using any

media with a length less than 127 mm

(

5 in). This may be

caused by paper that has been affected by environmental

conditions. For optimum performance, make sure you are

storing and handling the paper correctly. Please refer to

“Printer and Paper Storage Environment” on page 8.3.

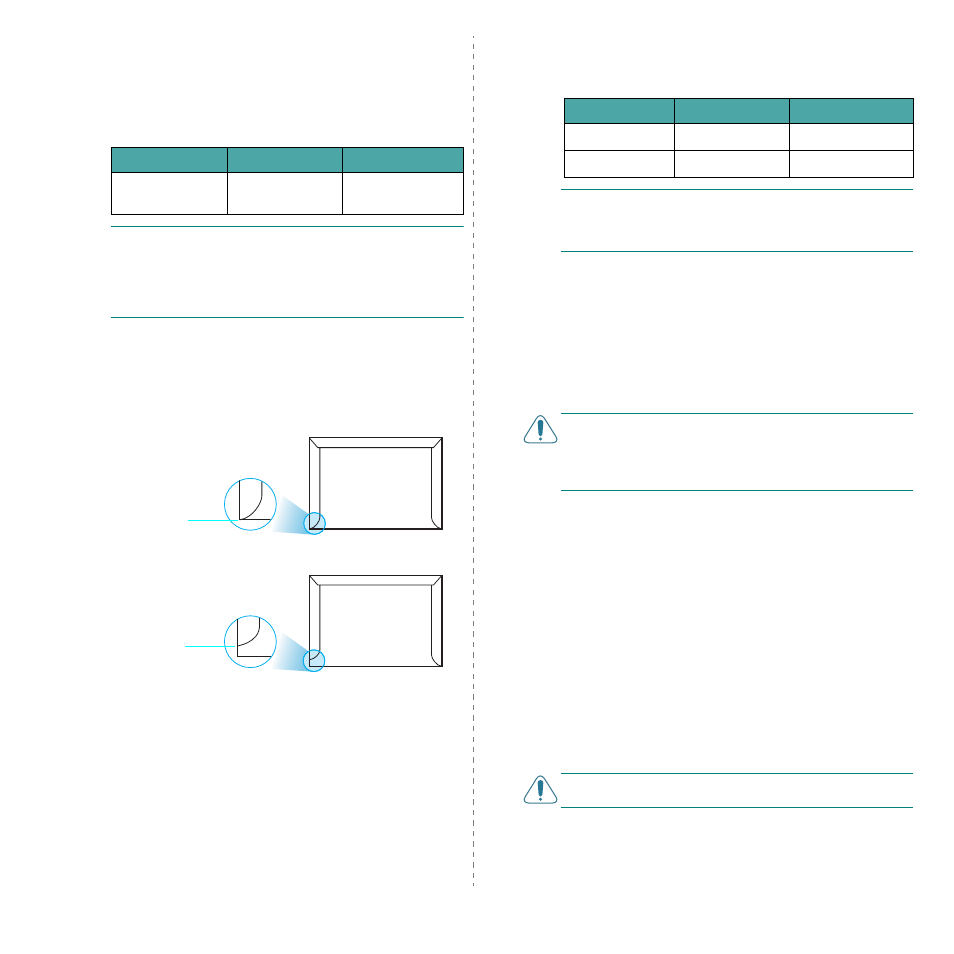

Envelopes with Double Side Seams

Double side-seam construction has vertical seams at both ends

of the envelope rather than diagonal seams. This style may be

more likely to wrinkle. Be sure the seam extends all the way to

the corner of the envelope as illustrated below.

Envelopes with Adhesive Strips or Flaps

Envelopes with a peel-off adhesive strip or with more than one

flap that folds over to seal must use adhesives compatible with

the heat and pressure in the printer. The extra flaps and strips

might cause wrinkling, creasing, or even jams, and may even

damage the fuser.

Minimum

Maximum

Tray

3 x 5 in

(76 x 127 mm)

8.5 x 14 in

(216 x 356 mm)

Correct

Incorrect

Envelope Margins

The following gives typical address margins for a commercial

#10 or DL envelope.

N

OTES

:

• For best print quality, position margins no closer than 0.6 in

(15 mm) from the edges of the envelope.

• Avoid printing over the area where the envelope’s seams meet.

Envelope Storage

Proper storage of envelopes helps contribute to print quality.

Envelopes should be stored flat. If air is trapped in an envelope,

creating an air bubble, then the envelope may wrinkle during

printing. See “Printing on Envelopes” on page 3.3.

Labels

C

AUTION

:

• To avoid damaging the printer, use only labels recommended

for laser printers.

• Never print on the same sheet of labels more than once and

never print on a partial sheet of labels.

When selecting labels, consider the quality of each component:

• Adhesives: The adhesive material should be stable at 180 °C

(356 °F), the printer’s fusing temperature.

• Arrangement: Only use labels with no exposed backing

between them. Labels can peel off sheets with spaces

between the labels, causing serious jams.

• Curl: Prior to printing, labels must lie flat with no more than

0.5 in (13 mm) of curl in any direction.

• Condition: Do not use labels with wrinkles, bubbles, or other

indications of separation.

See “Printing on Labels” on page 3.3.

Transparencies

Transparencies used in the machine must be able to withstand

180 °C (356 °F), the machine’s fusing temperature.

C

AUTION

: To avoid damaging the machine, use only

transparencies recommended for use in laser printers.

Type of Address

Minimum

Maximum

Return address

0.6 in (15 mm)

2 in (51 mm)

Delivery address

2 in (51 mm)

3.5 in (90 mm)