Applications, Siemens building technologies, inc. 13 – Siemens BACNET 125-699 User Manual

Page 21

Applications

Siemens Building Technologies, Inc.

13

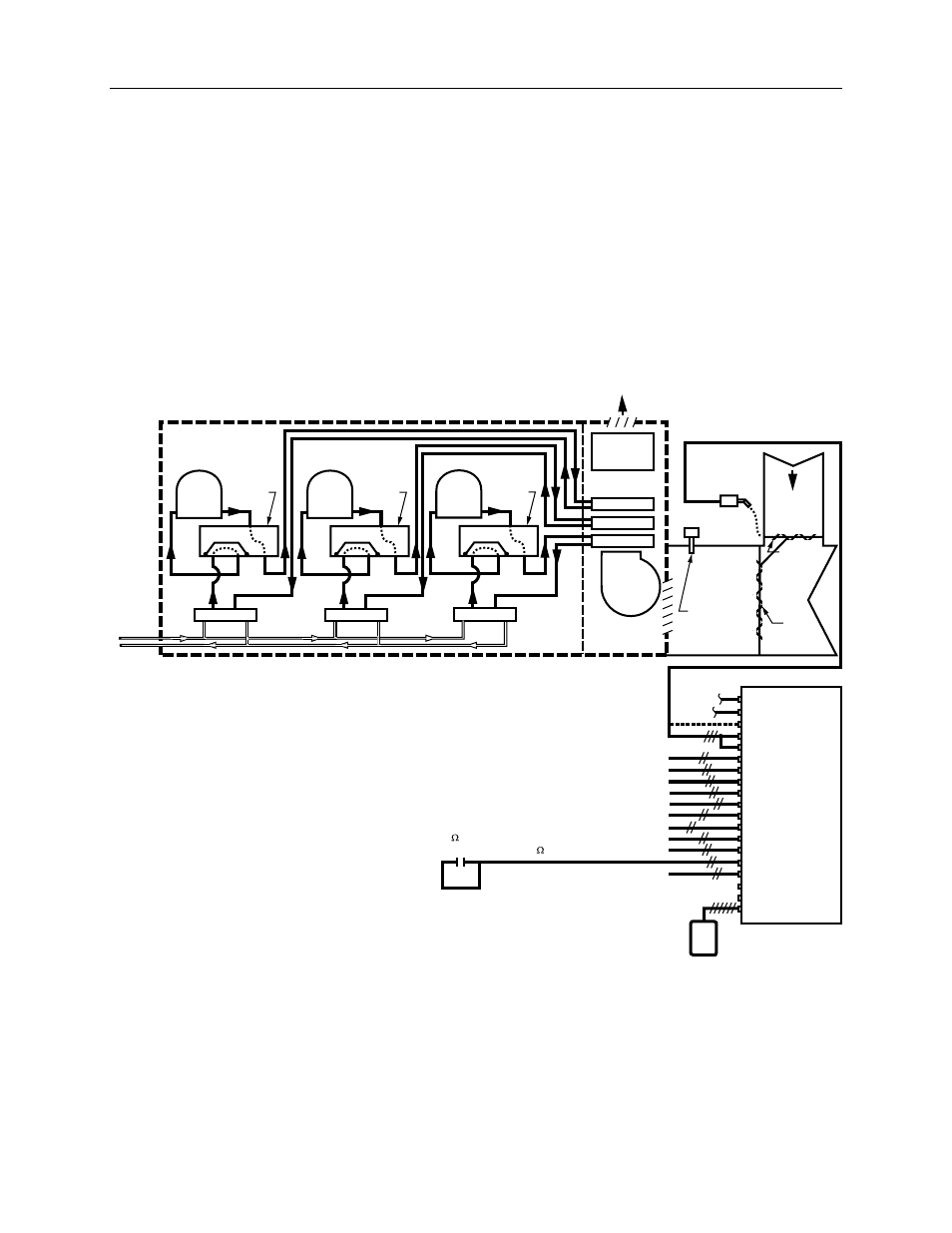

4. In this application, the maximum configurations are as follows:

• The maximum of CMP TOTL = 3.

• The maximum of EHTG STG CNT = 3.

• The maximum of CMP TOTL plus EHTG STG CNT = 4.

If these limits are exceeded, CMP TOTL will be set to 0 and EHTG STG CNT will be set

to 0. These points will remain at 0 until they are set correctly. This prevents the

application from trying to use the same DO as both a compressor and a stage of electric

heat.

FLN TRUNK

AO1 (0-10V)

DO1

DO2

DO3

DO4

DO5

DO6

DO7

DO8

DI3/AI3

DI4/AI4

DI5/AI5

DI2

DI6

AO2 (0-10V)

AO3 (0-10V)

RTS

N.O.

HEAT PUMP

CONTROLLER -

MULTI-STAGE

RTS

TEC2573CDR1

FAN

WALL

SWITCH

(OPTIONAL)

ELECTRIC

HEAT

(OPTIONAL)

COIL

HEATING /

COOLING

COIL

WATER

SOURCE

COMPRESSOR 3

REVERSING

VALVE

SUPPLY AIR

O.A.

N.C.

R.A.

1ST STAGE ELECTRIC HEAT (OPTIONAL)

REVERSING VALVE

COMPRESSOR 1

COMPRESSOR 2; OR 3RD STAGE ELECTRIC HEAT (OPTIONAL)

COMPRESSOR 3; OR 2ND STAGE ELECTRIC HEAT (OPTIONAL)

FAN

SPARE AI (0-10V or 4-20mA) OR SPARE DI (DRY CONTACT)

SPARE AI (10K THERMISTOR) OR SPARE DI (DRY CONTACT)

MIXED AIR TEMPERATURE SENSOR 10K THERMISTOR (OPTIONAL)

HEAT PUMP ALARM (OPTIONAL)

N.O.

* THE O.A. AND R.A. DAMPERS MUST

BE MECHANICALLY LINKED.

R.A.

DAMPER*

(OPTIONAL)

MIXED AIR

TEMPERATURE

SENSOR

(OPTIONAL)

COMPRESSOR 1

REVERSING

VALVE

COIL

COMPRESSOR 2

REVERSING

VALVE

COIL

COIL

COIL

O.A.

DAMPER*

(OPTIONAL)

24 V-AC

*

ON BOARD, AO1 IS GROUPED PYSICALLY WITH AO2 AND AO3

*

Figure 5. Application 2583 Control Drawing.