Siemens Chem-Ad Series User Manual

Water technologies, Key benefits

Water Technologies

Wallace & Tiernan

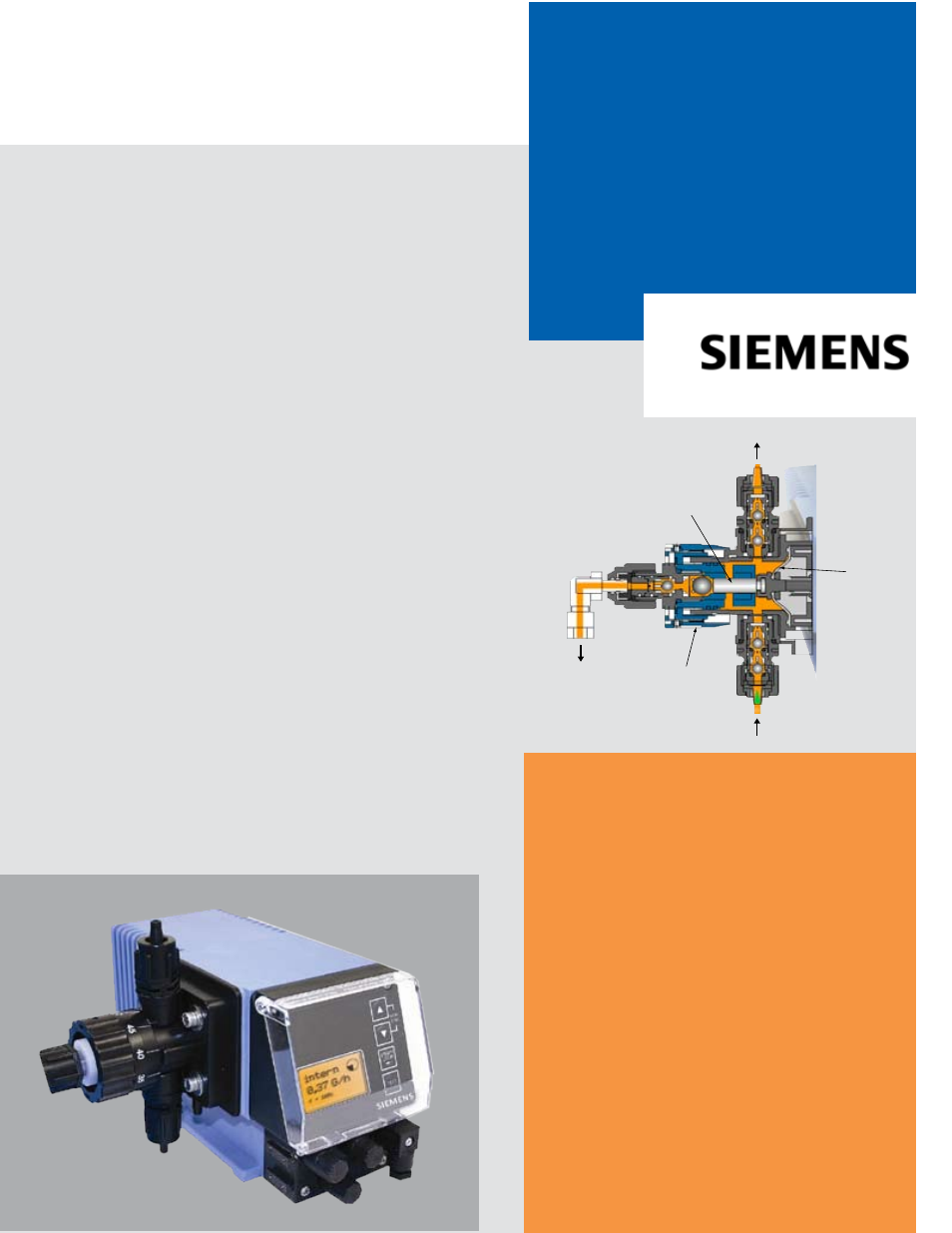

Chem-Ad® Series A

Diaphragm Metering

Pump

Technical Information

TI 440.600-1 UA

Key Benefits:

Dependable low capacity metering from 0.06

USGPH (0.2 LPH) to 0.44 USGPH (0.5 LPH) and back

pressures to 120 PSI (10 BAR @ 50 Hz)

Reliable metering of most multi-phase fluids,

particularly Sodium Hypochlorite, with integral

auto de-gasing

Flexible automatic signal input - analog or pulse

Simple user-friendly pump calibration

Continuous accurate chemical dosing

Suitable for unmanned installations with auto

controls and optional flow monitoring

Easy to read back-lit digital display of pump

capacity, strokes operating mode and alarm

Low maintenance PVDF head standard

Corrosion resistant IP65 enclosure

CE marked electronics

•

•

•

•

•

•

•

•

•

•

The Wallace & Tiernan Chem-Ad Series A is an electronically

controlled, motor driven diaphragm metering pump. It is

designed specifically for very low feedrate applications,

particularly sodium hypochlorite. The pump features a

unique, constant circulation liquid end with a calibrated,

adjustable plunger for precise feedrate control. This design

ensures consistent performance, even with chemicals that

tend to outgas, such as hypochlorite.

The Chem-Ad series of diaphragm metering pumps provided

by Siemens Water Technologies are designed to handle

the most demanding applications in the treatment of

potable water, swimming pools, wastewater and industrial

processes. A well-balanced range of capacities combines

with excellent reproducibility and optimal chemical

resistance. Chem-Ad metering pumps are of the positive

displacement-type driven by proven overload-proof motors.

Since they are available with a wide choice of configurations

ranging from manual to flow proportional to setpoint, these

pumps can cover any metering requirement.

The XL Series, shown below, features an integrated LED

display panel, touch-pad controls and multiple control

functions, including feedrate setpoint with closed-loop

control, flow/no-flow monitoring, batch operation and

feedrate display.

To Application

Return To

Supply

From Supply

Feedrate

Adjustment

Knob

Plunger

Re-Circulation

Diaphragm