Burner/blower removal (cont), Burner (cont) – State Industries GP650YTPDT User Manual

Page 14

Technical Literature Department

13 of 52

Ashland City, TN © 2008

Servicing should only be performed by a Qualified Service Agent

ULTRA HIGH EFFICIENCY POWER VENT/POWER DIRECT VENT - SERVICE MANUAL

BURNER (CONT)

Burner/Blower Removal (cont)

Service Notes - Blower Flange & Blower Adapter Gaskets.

Whenever the blower or burner is removed for service DO NOT overtighten the machine

screws that hold the blower flange to the blower adapter (page 12) or the blower adapter to

the water heater tank (above). Torque on these screws should not exceed 40 inch lbs.

If these mounting screws are overtightened the gaskets will be squeezed and deformed

from their natural shape. This can partially block the flow of the fuel air mixture and cause

rough starting, rough operation and ignition failure.

If these gaskets are deformed from overtightening the mounting screws it can also lead to

gasket leakage. Hot flue gases leaking from these points can burn up wiring, igniters, and

other components.

Blower Adapter

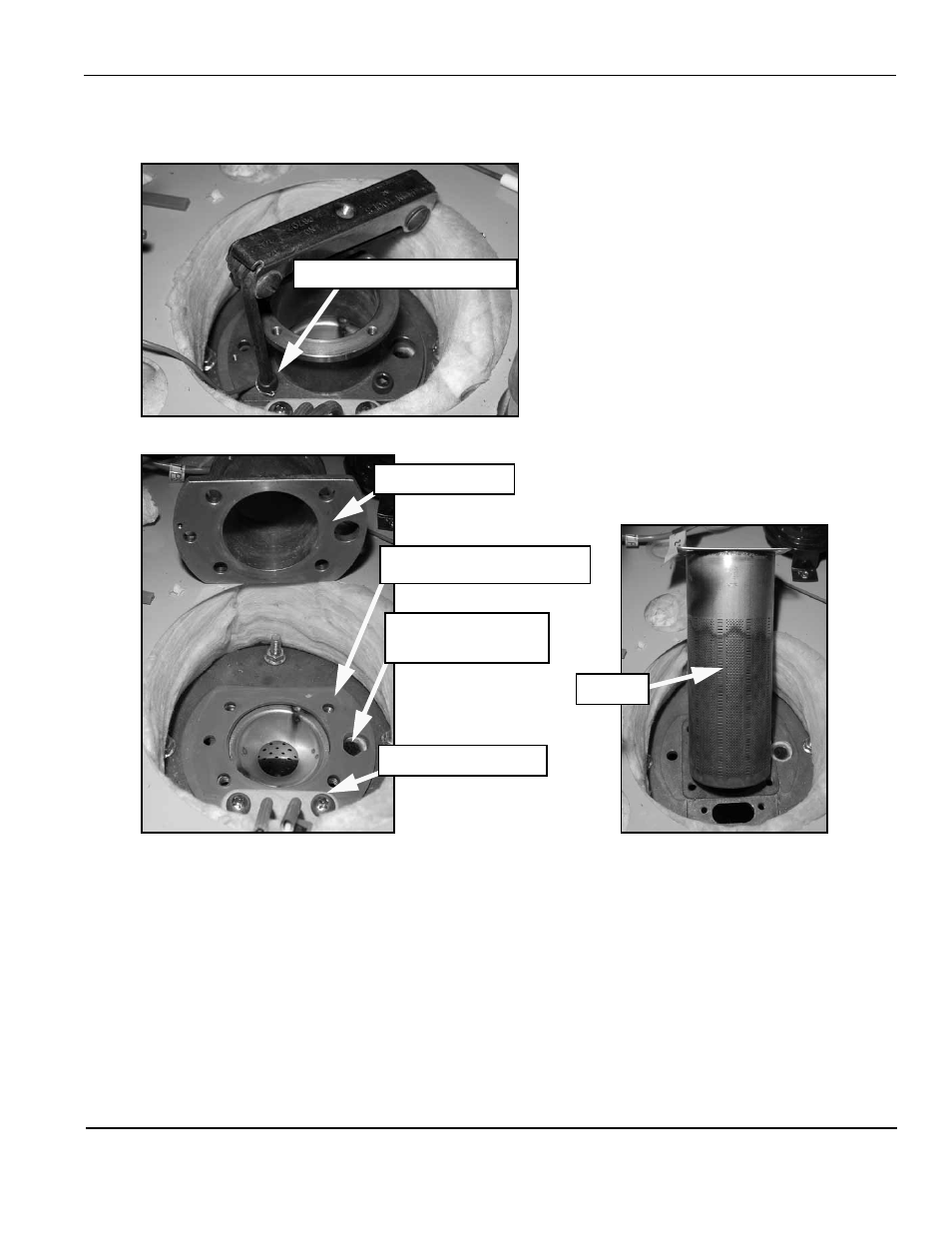

BLOWER/BURNER REMOVAL PROCEDURE

(CONT)

9 Remove 4 blower adapter 1/4” hex machine

screws. Do not over tighten when reinstalling -

torque should not exceed 40 inch lbs.

10 Remove the blower adapter.

11 Be extremely careful when handling the Sight

Glass inside the Burner View Port (page 11) this

can easily be dropped and lost - and the water

heater must have the sight glass in place to

operate safely.

12 Remove the hot surface igniter - 2 Phillips head

screws.

13 Remove the blower adapter gasket. Gasket may

be reused if not damaged or showing signs of

excessive wear.

14 Lift the burner up and out.

1/4” Hex Machine Screws

Hot Surface Igniter

Burner

Blower Adapter Gasket

Sight Glass inside

Burner View Port