Southbend EVS Tool Room lathe w/DRO SB1059F User Manual

Page 71

For Machines Mfg. Since 3/11

EVS Toolroom Lathe w/DRO

-69-

M A I N T E N A N C E

Checking & Adding Oil

Oil Type...Mobil DTE Light or ISO 32 Equivalent

Oil Amount .......................................... 15.9 Quarts

Check/Add Frequency .................................... Daily

Change Frequency ...................................Annually

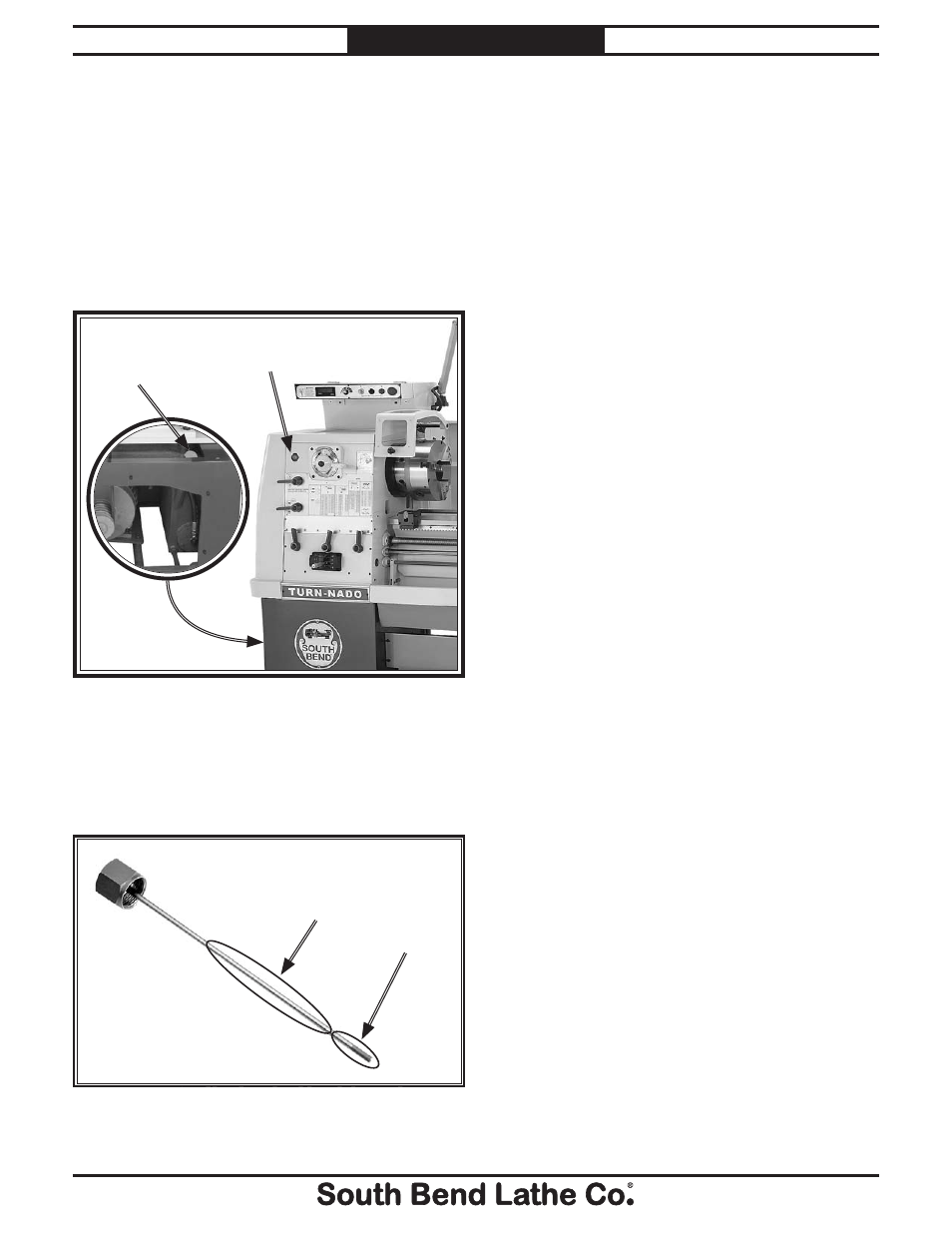

Use the oil sight glass shown in Figure 98 to

verify that oil is being pumped into the headstock

during operation. When the lathe is disconnected

from power, no oil will be seen in the sight glass.

The oil tank filler cap (see Figure 98) is fitted

with a dip stick for checking the headstock oil

level (see Figure 99). If the oil level is below the

full zone on the dip stick, add oil to the tank to

bring the level back into the full zone.

Figure 99. Headstock oil level dip stick.

Full Zone

Add Zone

Changing Headstock Oil

The headstock oil pump system must be cleaned

and the oil changed after the break-in period and

then annually (or every six months with heavy

service or extreme working conditions).

Since this lathe uses a base-mounted oil tank,

removing the drain plug and using a drain pan

is not a convenient option when changing the oil.

We recommend using a remote oil pump with a

suction hose that can be inserted through the

filler spout to the bottom of the oil tank instead.

If a remote oil pump system is not available,

use the headstock oil pump for this purpose, as

instructed below.

Items Needed:

Qty

5-Gallon Waste Oil Bucket with Lid .................... 1

Phillips Screwdriver #2 ........................................ 1

Standard Screwdriver #2 ...................................... 1

Funnel 8" ............................................................... 1

Hex Wrench 4mm ................................................. 1

Wrench 17mm ....................................................... 1

Wrench 25mm ....................................................... 1

Wrench 1

1

⁄

2

" ........................................................... 1

Mineral Spirits ................................... As Required

Rags .................................................... As Required

Gasket or Automotive Silicone Sealant ............... 1

Hose Clamp ........................................

1

⁄

2

" Diameter

Drain Hose .....................................

3

⁄

8

" ID x 4' Long

Magnets .................................................... Optional

Figure 98. Headstock oil flow sight glass location.

Headstock Oil

Flow Sight Glass.

Tank Filler

Cap