Southbend EVS Tool Room lathe w/DRO SB1059F User Manual

Page 35

For Machines Mfg. Since 3/11

EVS Toolroom Lathe w/DRO

-33-

P R E P A R A T I O N

7.

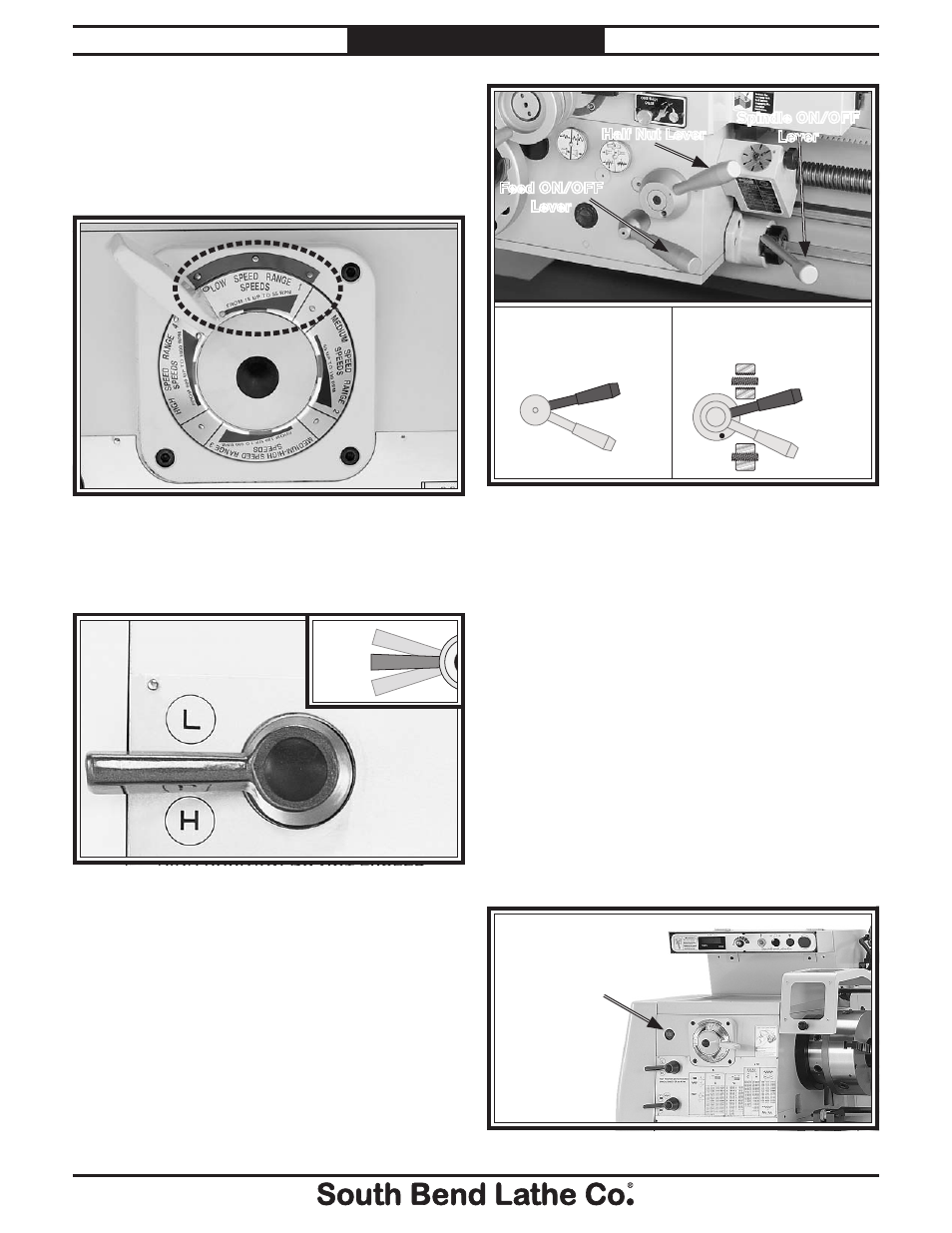

Move the spindle speed range lever to low

speed range 1 (18-55 RPM), as shown in

Figure 25.

Note:

You may need to rock the spindle back-

and-forth by hand to mesh the gears.

Figure 25. Spindle speed range lever.

8.

Move the gearbox range lever on the

headstock to the neutral (middle) position to

disable power feed, as shown in Figure 26.

Figure 26. Gearbox range lever in neutral.

L

OW

H

IGH

Neutral

9.

Pull up on the half nut and the feed ON/OFF

levers (see Figure 27), then use the carriage

handwheel to move the carriage back and

forth to ensure that it is not engaged with

the leadscrew or feed rod.

Note:

Steps 8–9 will ensure that the carriage

and cross slide do not unexpectedly move

during the following steps.

10.

To prevent the spindle from rotating when

power is applied to the motor, move the

spindle ON/OFF lever to the OFF (middle)

position (see Figure 27).

11.

Turn the master power switch ON, then

reset the STOP button by twisting it

clockwise until it pops out. The headstock oil

pump will turn ON.

12.

Observe the oil pump tube through the sight

glass on the headstock (see Figure 28).

Verify that you see oil flowing.

Important:

The headstock has a pressurized oil

system that is equipped with a pressure

safety switch. If the oil is not properly

flowing, the lathe will not start.

Figure 27. Apron controls for test run.

Half Nut Lever

Spindle ON/OFF

Lever

Feed ON/OFF

Lever

Engaged

Disengaged

Engaged

Disengaged

Half Nut Lever

and Half Nut

Feed ON/OFF

Lever

Figure 28. Headstock oil sight glass.

Verify oil is

flowing here