Chuck & faceplate mounting, Installation & removal devices – Southbend EVS Tool Room lathe w/DRO SB1059F User Manual

Page 39

For Machines Mfg. Since 3/11

EVS Toolroom Lathe w/DRO

-37-

O P E R A T I O N

Chuck & Faceplate

Mounting

This lathe ships with the 3-jaw chuck installed.

This is a scroll-type chuck where all three jaws

move in unison when the chuck key is used.

The included 4-jaw chuck features independent

jaws, which are used for square or unevenly-

shaped stock, and to mount work that needs to

be adjusted to near zero total indicated runout.

If neither chuck can hold your workpiece, the

cast iron faceplate has slots for T-bolts that hold

standard or custom clamping hardware. With the

correct clamping hardware, this faceplate will

hold non-cylindrical parts.

Installation & Removal

Devices

Because chucks are heavy and often awkward to

hold, some kind of lifting, support, or protective

device should be used during installation or

removal. The weight and size of the chuck will

determine the appropriate device to use (refer to

the following figure for examples).

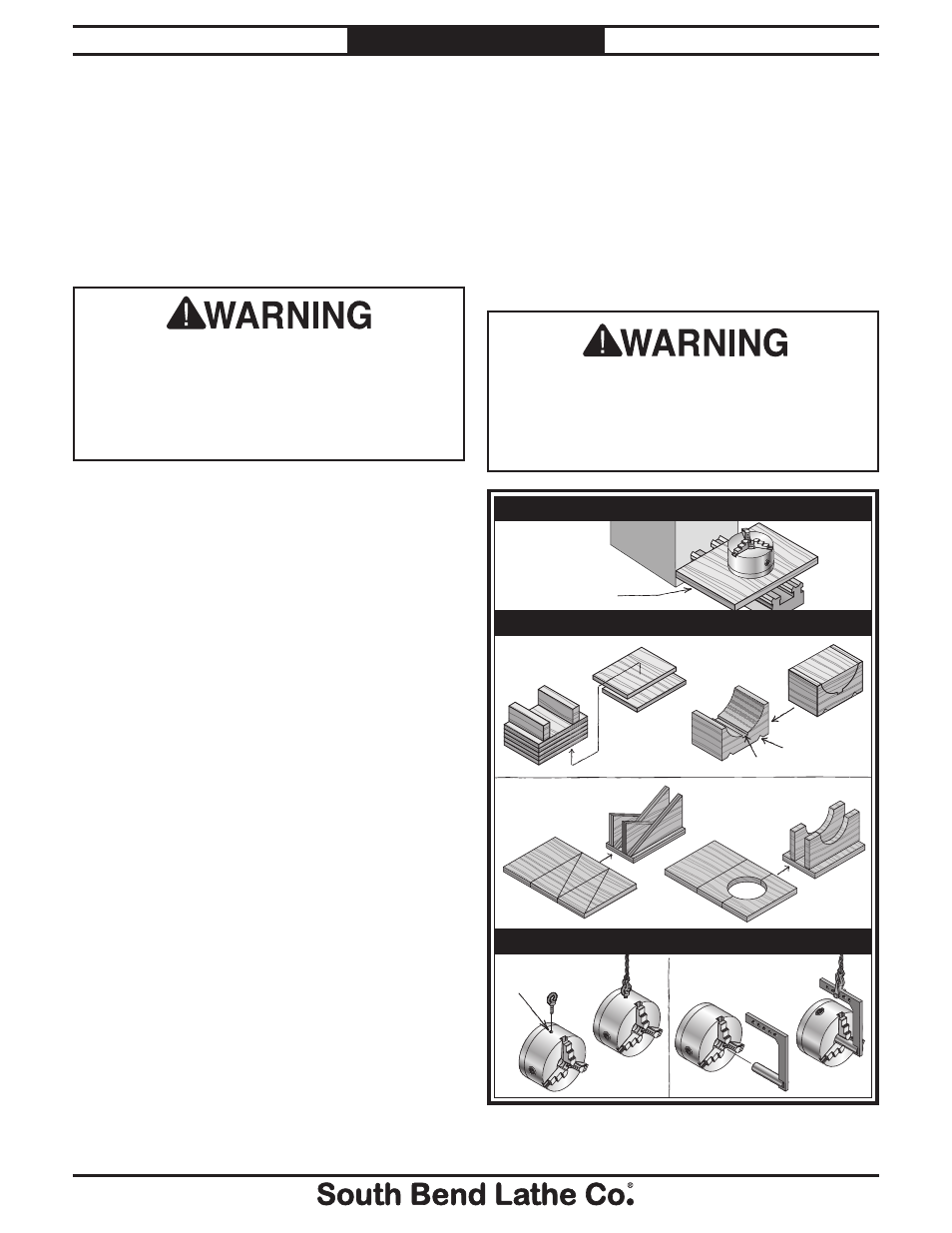

Pre-Threaded Hole

for Lifting Eye

Way Slot

Jaw Slot

Plywood & 2x4

Chuck Cradle

Plywood Chuck Cradle

(Straight Cuts)

Plywood Chuck Cradle

(Curved Cuts)

Fabricated Steel

Lifting Hook

Solid Block

Chuck Cradle

Plywood Protection

Plate for Chucks

Installed by Hand

SMALL, LIGHTWEIGHT CHUCKS

MEDIUM-SIZE, HEAVY CHUCKS

LARGE, VERY HEAVY CHUCKS

Figure 29. Examples of common devices used during

chuck installation and removal.

A dropped chuck can cause amputation,

serious crushing injuries, or property damage.

Always use a lifting, support, or protective

device to reduce this risk when installing or

removing a chuck.

This lathe is equipped with a D1-type spindle

nose. This type of spindle uses camlocks that are

adjusted with a chuck key to securely mount a

chuck or faceplate with repeatable precision and

ease.

Never use spindle speeds faster than the

chuck RPM rating or the safe limits of your

workpiece. Excessive spindle speeds greatly

increase the risk of the workpiece or chuck

being thrown from the machine with deadly

force!